At its core, a vacuum furnace benefits material processing by creating an exceptionally clean and controlled environment. By removing atmospheric gases like oxygen and nitrogen, it fundamentally prevents unwanted chemical reactions such as oxidation and contamination, allowing for heat treatment that preserves or enhances the intrinsic properties of the material.

The primary advantage of a vacuum furnace is not just the application of heat, but the removal of the atmosphere. This single action eliminates the root cause of most heat-related defects, ensuring that the final material is defined by its intended composition and structure, not by unintended chemical reactions.

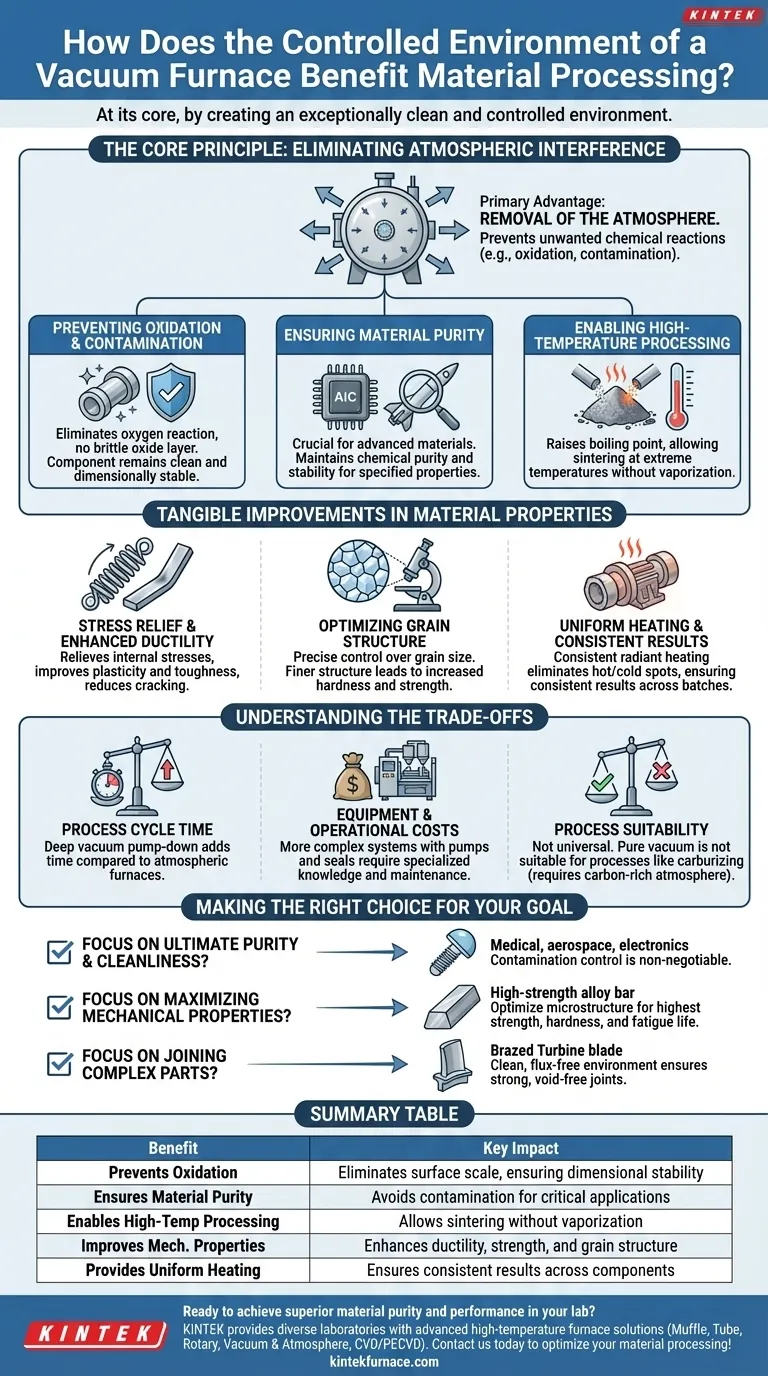

The Core Principle: Eliminating Atmospheric Interference

The defining feature of a vacuum furnace is its ability to create a "negative" atmosphere. By pumping out reactive gases, it provides a stable environment where heat can do its work without causing unintended side effects.

Preventing Oxidation and Contamination

The most immediate benefit of removing air is the prevention of oxidation. When heated, most metals readily react with oxygen, forming a brittle, undesirable oxide layer (scale) on the surface.

A vacuum environment eliminates this risk entirely. This ensures the component remains clean, dimensionally stable, and free from surface impurities that can compromise its performance.

Ensuring Material Purity

For advanced materials used in aerospace, medical, and electronics, even trace amounts of contamination can be catastrophic. A vacuum furnace guarantees that no foreign elements from the atmosphere are introduced during the heating cycle.

This maintains the chemical purity and stability of the material, which is critical for achieving its specified electrical, mechanical, or chemical properties.

Enabling High-Temperature Processing

Certain processes require temperatures so high that materials would vaporize at normal atmospheric pressure. By lowering the pressure, a vacuum raises the boiling point of these elements.

This allows processes like sintering to occur at extreme temperatures. Materials can be heated until they begin to densify and fuse together without turning into a gas, which is essential for creating strong, dense parts from powdered metals or ceramics.

Tangible Improvements in Material Properties

Eliminating atmospheric interference directly translates into superior and more consistent material characteristics. The controlled environment allows for precise manipulation of a material's internal structure.

Stress Relief and Enhanced Ductility

Vacuum annealing is highly effective at relieving internal stresses built up during manufacturing processes like machining or forming.

This controlled heating and cooling cycle, free from the risk of oxidation, improves the material's plasticity (ductility) and toughness, making it less prone to cracking under load.

Optimizing Grain Structure

Heat treatment in a vacuum allows for precise control over the material's crystalline or grain structure. This process can be used to refine grain size, which directly impacts mechanical properties.

For many alloys, a finer grain structure leads to increased hardness and strength, making vacuum treatment essential for high-performance and high-strength applications.

Uniform Heating and Consistent Results

Modern vacuum furnaces provide exceptional temperature uniformity. The absence of air currents allows for highly consistent radiant heating, ensuring that the entire part—regardless of its geometry—reaches the target temperature at the same time.

This uniformity eliminates hot and cold spots, guaranteeing consistent results across the entire component and from one batch to the next.

Understanding the Trade-offs

While powerful, a vacuum furnace is not a universal solution. Its benefits come with practical considerations.

Process Cycle Time

Achieving a deep vacuum requires a "pump-down" phase, which adds time to the overall process cycle compared to an atmospheric furnace. The time required depends on the furnace size and desired vacuum level.

Equipment and Operational Costs

Vacuum furnaces are more complex and expensive to purchase and maintain than their atmospheric counterparts. The vacuum pumps, seals, and control systems require specialized knowledge and regular servicing.

Process Suitability

Not all heat treatments benefit from a pure vacuum. Some processes, such as carburizing, require a specific, carbon-rich atmosphere to diffuse carbon into the steel's surface. While many vacuum furnaces can perform this by backfilling with a controlled gas, a pure vacuum would be counterproductive.

Making the Right Choice for Your Goal

The decision to use a vacuum furnace should be driven by the required quality and performance of the final component.

- If your primary focus is ultimate purity and cleanliness: For medical implants, aerospace components, or sensitive electronics, the contamination control of a vacuum furnace is non-negotiable.

- If your primary focus is maximizing mechanical properties: To achieve the highest levels of strength, hardness, and fatigue life in advanced alloys, vacuum treatment provides the control needed to optimize the material's microstructure.

- If your primary focus is joining complex parts: For high-strength brazing, the clean, flux-free environment of a vacuum ensures a strong, void-free joint that is impossible to achieve in open air.

Ultimately, choosing a vacuum furnace is an investment in achieving unparalleled control over your material's final integrity.

Summary Table:

| Benefit | Key Impact |

|---|---|

| Prevents Oxidation | Eliminates surface scale, ensuring dimensional stability |

| Ensures Material Purity | Avoids contamination for critical applications |

| Enables High-Temperature Processing | Allows sintering without vaporization |

| Improves Mechanical Properties | Enhances ductility, strength, and grain structure |

| Provides Uniform Heating | Ensures consistent results across components |

Ready to achieve superior material purity and performance in your lab? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our vacuum furnaces can optimize your material processing and deliver unmatched results!

Visual Guide

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What are the five main benefits of using a vacuum furnace chiller? Enhance Process Control and Product Quality

- What role does a high-temperature vacuum furnace play in the desilication of biomass? Achieve Ultra-High Purity Carbon

- Why is a vacuum annealing furnace necessary for PBF-LB/M titanium alloys? Optimize Material Integrity

- How does temperature control precision of industrial melting furnaces affect intermetallic phase selection?

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- How does a sintering furnace optimize Al/CNT green compacts? Achieve High Densification & Precision Microstructure

- What heating methods are available for vacuum graphitizing furnaces? Induction vs. Resistance Heating Explained

- Why is high-vacuum degasification necessary for HfO2 coatings? Prevent Ir Layer Delamination and Bubbling