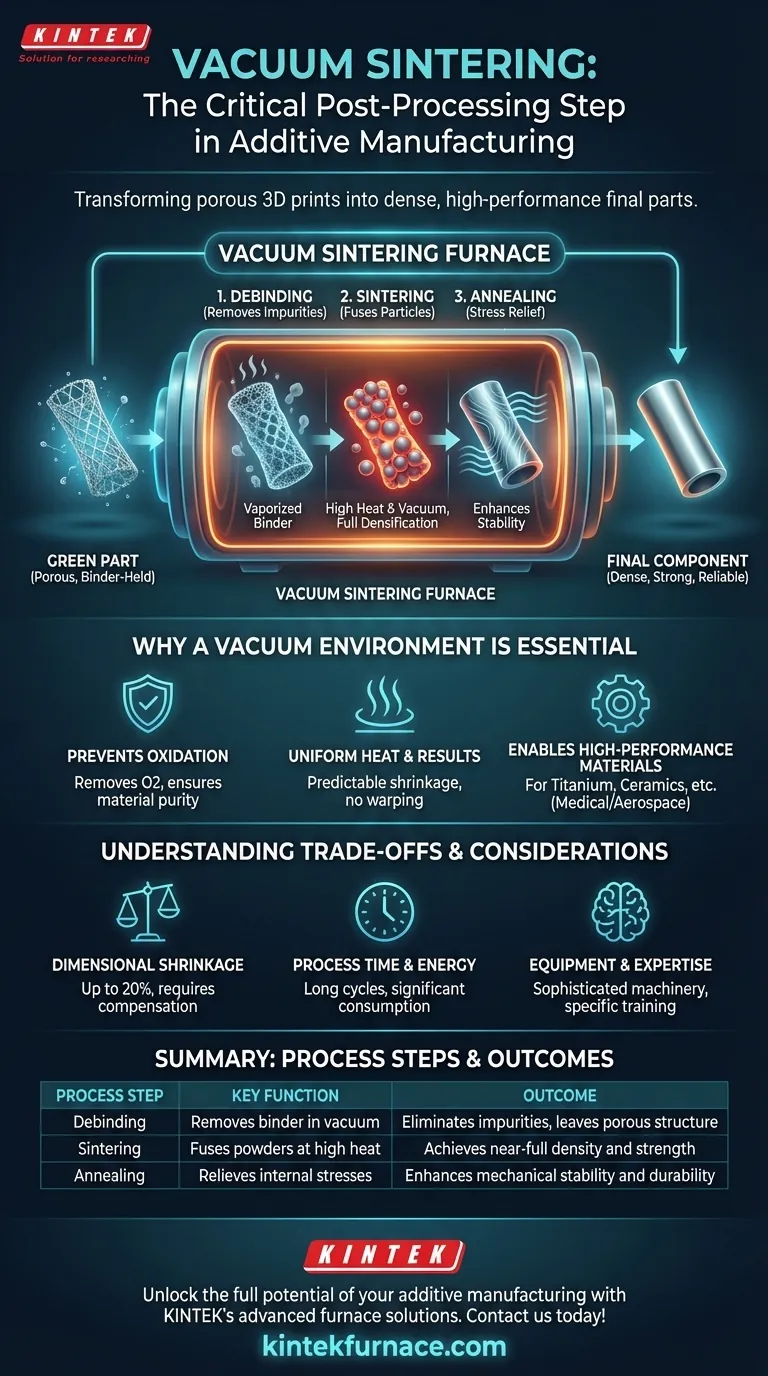

In additive manufacturing, a vacuum sintering furnace is the critical post-processing step that transforms a fragile, porous 3D printed object into a dense, high-performance final part. It uses a combination of high heat and a controlled vacuum environment to remove binding agents and fuse metal or ceramic powders together, achieving the material properties required for demanding applications.

The core function of a vacuum furnace is to perfect what the 3D printer starts. It turns a "green" part—a geometrically correct but structurally weak object—into a fully dense, strong, and reliable component ready for real-world use.

From "Green" Part to Final Component

The journey from a printed object to a functional part involves several distinct thermal processes, most of which occur within the vacuum furnace. This controlled environment is what guarantees the final quality.

The Initial "Green" State

After a metal 3D printing process like binder jetting, the initial output is known as a "green" part. This part has the correct shape but consists of metal powder held together by a polymer binder. It is brittle and has none of the mechanical properties of a solid metal.

Step 1: Debinding to Remove Impurities

The first stage inside the furnace is debinding. The part is gently heated to a temperature that vaporizes the binder material. The vacuum system then safely removes these vapors, leaving behind a fragile part made of loosely-connected metal powder.

Step 2: Sintering for Full Densification

Next, the temperature is raised significantly, approaching but not reaching the metal's melting point. This is sintering. At this high temperature, the metal particles fuse together, a process that eliminates the pores between them and densifies the part to near 100% of its theoretical density.

Step 3: Annealing for Stress Relief

The same furnace is often used for a final heat treatment cycle, such as annealing. This process relieves internal stresses that may have built up during the rapid heating and cooling of the printing and sintering stages, ultimately enhancing the part's final mechanical strength and stability.

Why a Vacuum Environment is Non-Negotiable

Performing these heating processes in a vacuum is not optional; it is fundamental to achieving a high-quality result. An open-air furnace would ruin the part.

Preventing Oxidation and Contamination

At the extreme temperatures required for sintering, reactive metals would instantly oxidize if exposed to air. This oxidation creates a weak, brittle layer and compromises the entire part's integrity. A vacuum removes oxygen and other atmospheric contaminants, ensuring material purity.

Ensuring Uniform Heat and Predictable Results

A vacuum provides a highly stable and uniform heating environment. This consistency is crucial for ensuring the part shrinks predictably and evenly. Inconsistent heating would lead to warping, internal defects, and a failed component.

Enabling High-Performance Materials

This process is essential for manufacturing parts from high-performance materials like titanium, stainless steel, or technical ceramics like zirconia. These materials are used in critical applications like medical implants, aerospace components, and high-precision instruments where material failure is not an option.

Understanding the Trade-offs

While essential, integrating vacuum sintering into a workflow introduces specific considerations that must be managed for success.

Critical Factor: Dimensional Shrinkage

During sintering, as the part densifies, it shrinks. This shrinkage can be significant—often up to 20%—but it is highly predictable. The initial 3D model must be designed larger to compensate for this exact shrinkage, requiring careful engineering and material science knowledge.

Process Time and Energy Consumption

Debinding and sintering are not fast processes. A single furnace cycle can take many hours or even days depending on the part size and material. While modern furnaces are designed for energy efficiency with advanced insulation, they still represent a significant portion of the total production time and energy cost.

Equipment and Expertise

Vacuum sintering furnaces are sophisticated and expensive pieces of industrial equipment. Operating them correctly requires specific training and expertise to manage heating profiles, vacuum levels, and safety protocols for different materials.

Making the Right Choice for Your Goal

Integrating vacuum sintering is a strategic decision based on your final application requirements. It's the key that unlocks the full potential of certain additive manufacturing technologies.

- If your primary focus is maximum material performance: Vacuum debinding and sintering are mandatory to achieve the density, strength, and purity required for functional, load-bearing metal and ceramic parts.

- If your primary focus is high dimensional accuracy: You must precisely calculate and compensate for material shrinkage in your initial CAD design to ensure the final sintered part meets specifications.

- If your primary focus is end-use parts for demanding industries: The quality assurance provided by a controlled vacuum environment is essential for meeting the stringent standards of the medical, aerospace, and high-precision instrumentation sectors.

Ultimately, the vacuum sintering furnace is what makes metal binder jetting and similar additive processes viable for producing true engineering-grade components.

Summary Table:

| Process Step | Key Function | Outcome |

|---|---|---|

| Debinding | Removes binder material in vacuum | Eliminates impurities, leaves porous structure |

| Sintering | Fuses metal/ceramic powders at high heat | Achieves near-full density and strength |

| Annealing | Relieves internal stresses | Enhances mechanical stability and durability |

Unlock the full potential of your additive manufacturing with KINTEK's advanced high-temperature furnace solutions. Our Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, backed by deep customization, ensure precise sintering for dense, reliable parts. Contact us today to discuss how we can meet your unique experimental and production needs!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How does a rotary tube furnace operate? Master Continuous Heating for Uniform Results

- What are the key advantages of rotary tube furnaces? Achieve Superior Uniformity and Efficiency for Your Materials

- How do rotary tube furnaces contribute to material science and chemical engineering? Unlock Precision in Material Processing

- How does the heating process work in rotary tube furnaces? Achieve Uniform Heat for Powders and Granules

- What other fields utilize rotary tube furnaces? Discover Versatile Heating Solutions for Multiple Industries