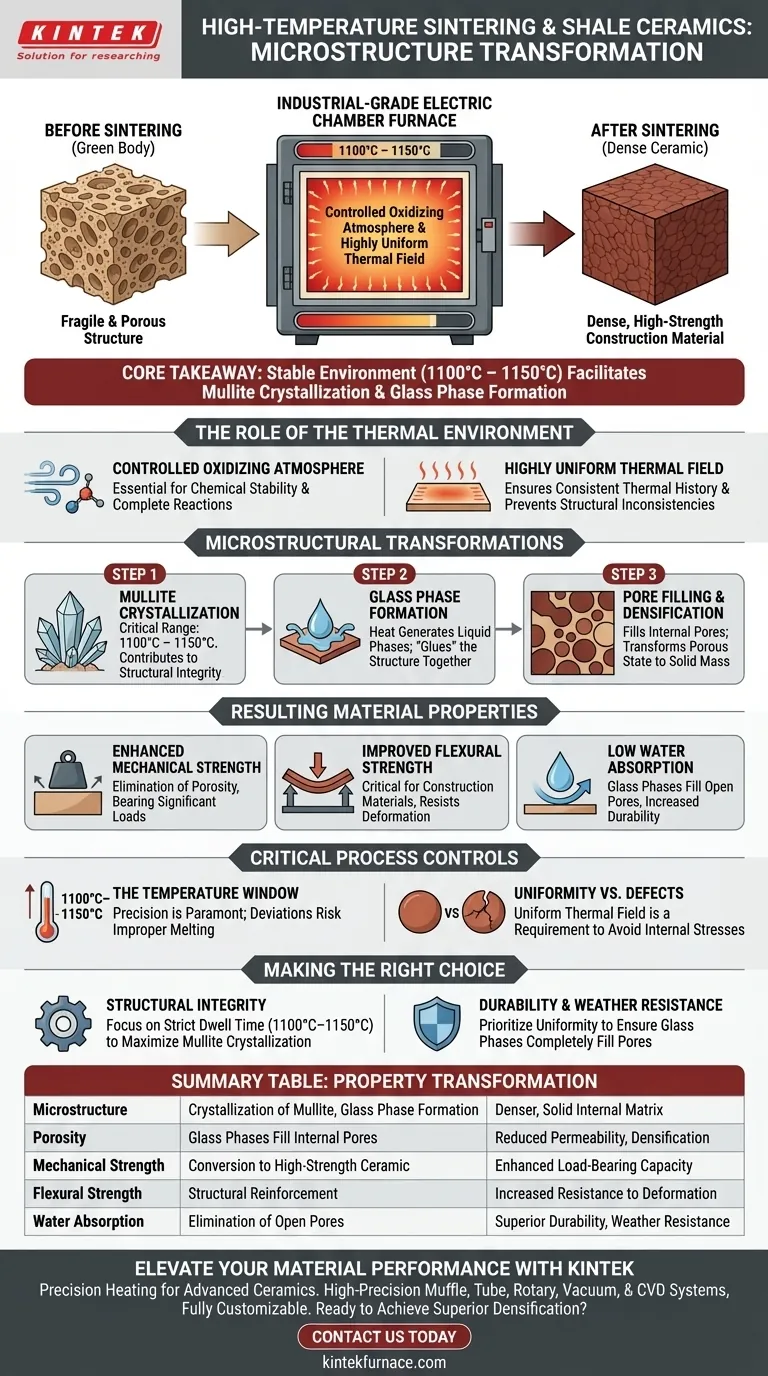

High-temperature sintering in an industrial-grade electric chamber furnace fundamentally alters the microstructure of shale ceramics. By subjecting the material to a controlled oxidizing atmosphere and a highly uniform thermal field, the process converts a fragile, porous green body into a dense, high-strength construction material. This transformation is driven by specific chemical and physical reactions that only occur within a precise temperature window.

Core Takeaway The furnace’s stable environment at temperatures between 1100°C and 1150°C facilitates the crystallization of mullite and the formation of glass phases. This fills internal pores, resulting in ceramics with significantly improved flexural strength and low water absorption.

The Role of the Thermal Environment

Controlled Oxidizing Atmosphere

The electric chamber furnace provides a controlled oxidizing atmosphere. This specific environmental condition is essential for the chemical stability of shale ceramics during the heating process. It allows for complete physical and chemical reactions to take place throughout the material.

Highly Uniform Thermal Field

Success in sintering relies on consistency. Industrial-grade electric furnaces are designed to maintain a highly uniform thermal field. This ensures that every part of the ceramic body experiences the same thermal history, preventing structural inconsistencies.

Microstructural Transformations

Mullite Crystallization

At the critical temperature range of 1100°C to 1150°C, the material undergoes a phase change. The furnace environment facilitates the crystallization of new mullite phases. Mullite is a key silicate mineral that contributes heavily to the structural integrity of the final ceramic.

Glass Phase Formation

Simultaneously, the heat generates glass phases within the ceramic matrix. These liquid-like phases flow into the microscopic voids within the material. This action effectively "glues" the structure together.

Pore Filling and Densification

The combination of mullite growth and glass phase formation fills the pores of the original green body. This transforms the material from a porous, permeable state into a dense, solid mass.

Resulting Material Properties

Enhanced Mechanical Strength

The primary outcome of this microstructural change is a dramatic increase in mechanical strength. The elimination of porosity creates a more robust internal structure capable of bearing significant loads.

Improved Flexural Strength

Specifically, the process imparts significantly improved flexural strength. This property—the ability to resist deformation under load—is critical for shale ceramics used as construction materials.

Low Water Absorption

Because the glass phases fill the open pores, the final product exhibits low water absorption. This makes the ceramic more durable and resistant to environmental weathering.

Critical Process Controls

The Temperature Window

Precision is paramount. The reactions required to strengthen shale occur specifically between 1100°C and 1150°C. Deviating from this range may fail to trigger the necessary crystallization or lead to improper melting.

Uniformity vs. Defects

The furnace's ability to provide a uniform thermal field is not a luxury; it is a requirement. Without it, uneven sintering would occur, leading to internal stresses or incomplete reactions in parts of the ceramic batch.

Making the Right Choice for Your Goal

To maximize the quality of your shale ceramics, focus on the specific parameters of your sintering cycle:

- If your primary focus is Structural Integrity: Ensure your furnace can maintain a strict dwell time within the 1100°C–1150°C window to maximize mullite crystallization.

- If your primary focus is Durability and Weather Resistance: Prioritize the uniformity of the thermal field to ensure glass phases completely fill pores throughout the entire batch, minimizing water absorption.

By controlling the thermal field and oxidation, you turn raw shale into a high-performance engineering material.

Summary Table:

| Property Transformation | Effect of High-Temp Sintering (1100°C - 1150°C) | Resulting Benefit |

|---|---|---|

| Microstructure | Crystallization of mullite and glass phase formation | Denser, more solid internal matrix |

| Porosity | Glass phases fill internal pores and microscopic voids | Reduced permeability and densification |

| Mechanical Strength | Conversion of green body to high-strength ceramic | Enhanced load-bearing capacity |

| Flexural Strength | Structural reinforcement via thermal history | Increased resistance to deformation |

| Water Absorption | Elimination of open pores | Superior durability and weather resistance |

Elevate Your Material Performance with KINTEK

Precision is the difference between fragile shale and high-performance ceramics. At KINTEK, we understand that a uniform thermal field and stable oxidizing atmosphere are critical to your research and production success.

Backed by expert R&D and manufacturing, KINTEK offers high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other lab high-temp furnaces—all fully customizable to meet your specific temperature windows and sintering requirements.

Ready to achieve superior material densification? Contact us today to discover how our advanced heating solutions can optimize your ceramic properties.

Visual Guide

References

- Carla Candeias, Fernando Rocha. Clay Schists from Barrancos (Portugal): An Approach Toward Sustainable Ceramic Raw Material Use. DOI: 10.3390/min15080852

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What role does a muffle furnace play in RH-SNP preparation? Master the Dual-Stage Thermal Synthesis

- What options are available for temperature uniformity in Box Furnaces? Achieve Precise Heat for Your Critical Processes

- What are the key considerations for temperature control when using a Muffle furnace? Master Precise Thermal Management

- What safety measures should be observed around the muffle furnace? Essential Protocols for Safe Operation

- What role does an air vent play in muffle furnaces? Master Atmosphere Control for Precise Results

- What factors should be considered before buying a muffle furnace? Ensure Safety and Efficiency for Your Lab

- What are the disadvantages of a muffle furnace? Understanding Key Limitations for Your Lab

- How does an elevator high-temperature furnace ensure process efficiency? Optimize S53P4 Bioactive Glass Production