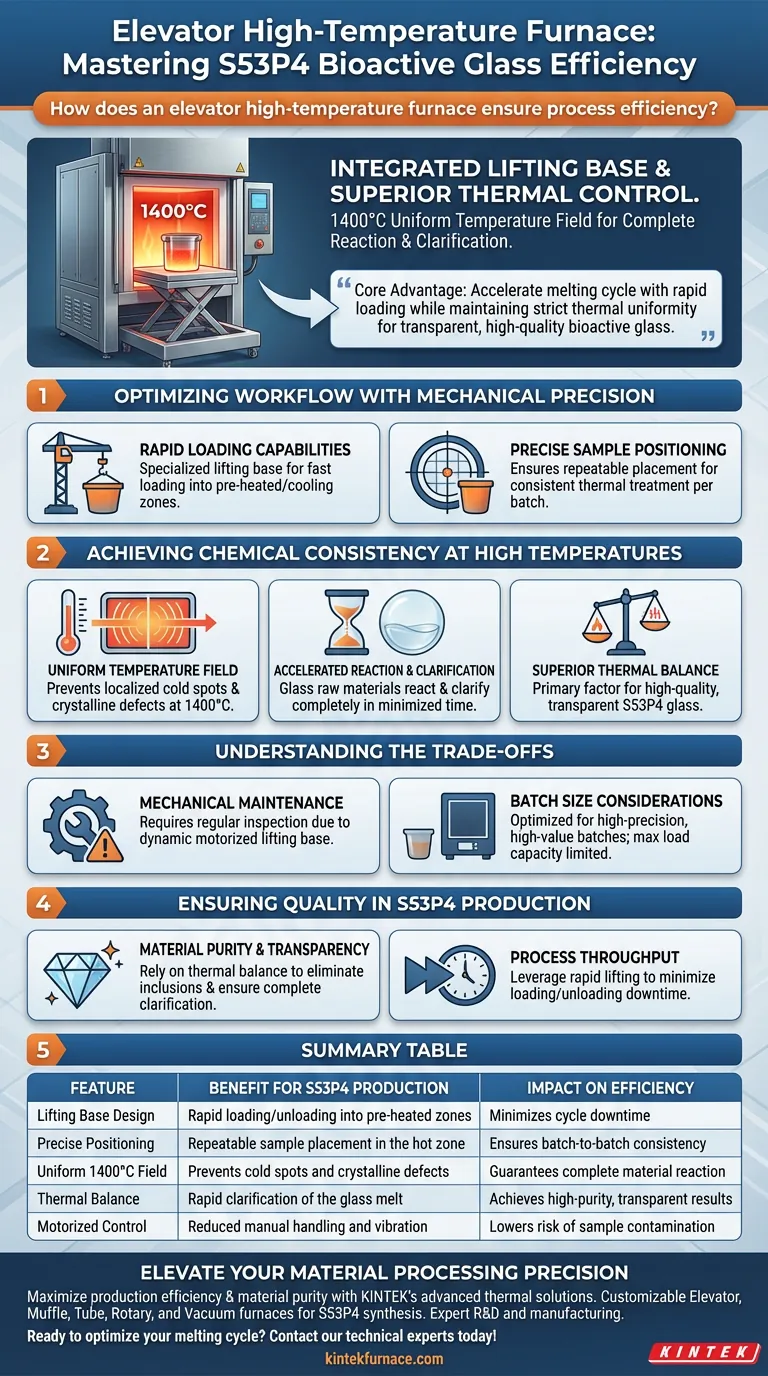

The efficiency of an elevator high-temperature furnace stems from its integrated lifting base and superior thermal control capabilities. This design allows for rapid loading and precise sample positioning, while maintaining a uniform temperature field at 1400°C to ensure complete reaction and clarification of raw materials in a short timeframe.

The core advantage of this furnace architecture is its ability to accelerate the melting cycle through rapid mechanical loading while maintaining the strict thermal uniformity required to produce transparent, high-quality bioactive glass.

Optimizing Workflow with Mechanical Precision

Rapid Loading Capabilities

The furnace utilizes a specialized lifting base design. This mechanism facilitates the rapid loading of the crucible directly into the pre-heated zone or controlled cooling zone.

Precise Sample Positioning

The lifting action ensures precise positioning of the S53P4 samples within the heating chamber. This repeatability is crucial for ensuring every batch receives the exact same thermal treatment.

Achieving Chemical Consistency at High Temperatures

Uniform Temperature Field

At the required melting temperatures of 1400°C, the furnace maintains a highly uniform temperature field. This consistency prevents localized cold spots that could lead to crystalline defects or unreacted raw materials.

Accelerated Reaction and Clarification

The thermal uniformity ensures that glass raw materials react and clarify completely within a minimized timeframe. This speed increases overall process efficiency by reducing the time required for the melt to become homogenous.

Superior Thermal Balance

Thermal balance control is fundamental to the operation of this furnace. It is the primary factor in obtaining high-quality, transparent glass materials, which is a critical quality metric for bioactive glass.

Understanding the Trade-offs

Mechanical Maintenance Requirements

The inclusion of a motorized lifting base introduces mechanical complexity not found in static box furnaces. This dynamic component requires regular inspection to ensure smooth, vibration-free movement during the fragile molten stages.

Batch Size Considerations

While the design offers superior control, the lifting mechanism typically defines the maximum load capacity. This architecture is generally optimized for high-precision, high-value batches rather than bulk, lower-grade mass production.

Ensuring Quality in S53P4 Production

To maximize the benefits of an elevator high-temperature furnace for your specific production goals, consider the following:

- If your primary focus is material purity and transparency: Rely on the furnace's thermal balance control to eliminate unmelted inclusions and ensure complete clarification.

- If your primary focus is process throughput: Leverage the rapid lifting mechanism to minimize the downtime associated with manual loading and unloading procedures.

Ultimately, the elevator furnace transforms the melting process from a variable task into a precise, repeatable engineering cycle.

Summary Table:

| Feature | Benefit for S53P4 Production | Impact on Efficiency |

|---|---|---|

| Lifting Base Design | Rapid loading/unloading into pre-heated zones | Minimizes cycle downtime |

| Precise Positioning | Repeatable sample placement in the hot zone | Ensures batch-to-batch consistency |

| Uniform 1400°C Field | Prevents cold spots and crystalline defects | Guarantees complete material reaction |

| Thermal Balance | Rapid clarification of the glass melt | Achieves high-purity, transparent results |

| Motorized Control | Reduced manual handling and vibration | Lowers risk of sample contamination |

Elevate Your Material Processing Precision

Maximize your production efficiency and material purity with KINTEK’s advanced thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers high-performance Elevator, Muffle, Tube, Rotary, and Vacuum furnaces—all fully customizable to meet the rigorous demands of S53P4 bioactive glass synthesis and other high-temp lab applications.

Ready to optimize your melting cycle? Contact our technical experts today to discover how our customizable CVD and high-temperature systems can transform your lab’s throughput.

Visual Guide

References

- Jian Zheng, Julian R. Jones. Sol‐gel derived S53P4 bioactive glass. DOI: 10.1111/jace.70090

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the significance of controlling the heating rate of a muffle furnace? Master Biochar Pyrolysis Parameters

- What is the role of high-temperature furnaces in 3D-printed glass debinding? Mastering the Silica Foundation

- What is the function of a laboratory high-temperature muffle furnace in niobate phosphor synthesis?

- What is the role of a high-temperature muffle furnace in solid-state synthesis? Master CaMnO3 Perovskite Production

- What are the benefits of atmosphere control in muffle furnaces? Unlock Precise Material Processing

- What are the common applications of box furnaces? Versatile Heat Treatment for Metals, Ceramics, and Research

- What is the necessity of cleaning and drying activated carbon supports in a muffle furnace? Unlock Peak Catalyst Performance

- What is the function of an industrial muffle furnace in stir casting? Enhance Aluminum Matrix Composite Production