In short, atmosphere control gives you command over chemistry. It allows you to move beyond simple heating and precisely dictate the chemical environment your material is exposed to. This prevents unwanted reactions like oxidation, protects the integrity of sensitive materials, and even enables targeted surface modifications to achieve specific, improved properties.

Controlling the atmosphere inside a muffle furnace transforms it from a simple high-heat oven into a precise process tool. It allows you to dictate the chemical environment, preventing undesirable reactions and actively promoting beneficial ones to achieve specific material properties.

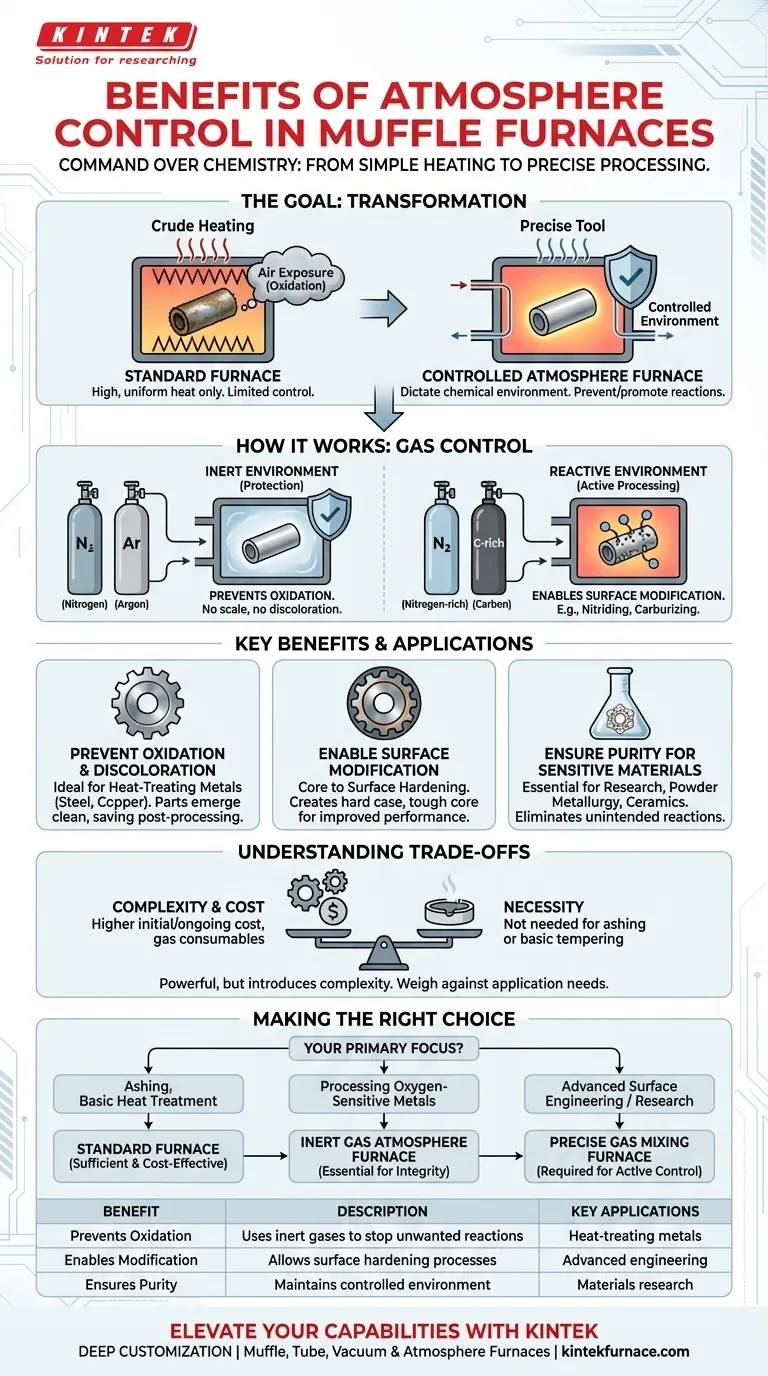

The Goal: From Crude Heating to Precise Processing

A standard muffle furnace excels at one thing: providing high, uniform heat while isolating the sample from the direct byproducts of combustion. This is a crucial first step. Atmosphere control is the next logical evolution, providing control over the gaseous environment within the heating chamber itself.

Creating a Chemically Inert Environment

The most common reason to control the furnace atmosphere is to prevent oxidation. At high temperatures, most materials will readily react with the oxygen present in ambient air.

By purging the chamber and flowing an inert gas, such as nitrogen or argon, you create a neutral environment. This protective blanket prevents oxygen from reaching the material's surface, stopping oxidation, scaling, and discoloration.

Introducing a Reactive Environment

Beyond simple protection, atmosphere control allows you to introduce specific gases to intentionally cause a chemical reaction on the material's surface.

This is a form of active processing. For example, introducing a nitrogen-rich atmosphere can be used for nitriding steel to harden its surface. Controlling the mix of reducing or oxidizing gases allows for highly specialized materials engineering.

Key Benefits in Practical Applications

Controlling the atmosphere directly translates to tangible improvements in process outcomes, material quality, and research validity.

Preventing Oxidation and Discoloration

For heat-treating metals like steel or copper, exposure to oxygen at high temperatures results in a layer of scale or oxide. This can ruin the surface finish and, in some cases, compromise the part's integrity.

An inert atmosphere ensures the part emerges from the furnace as clean as it went in, saving time and resources on post-processing cleaning or rework.

Enabling Deliberate Surface Modification

Atmosphere control is the core technology behind surface-hardening processes like carburizing or nitriding.

By introducing carbon- or nitrogen-rich gases at specific temperatures, you can diffuse these elements into the surface of a metal part. This creates a hard, wear-resistant outer case while maintaining a softer, tougher core, dramatically improving the material's performance.

Ensuring Purity for Sensitive Materials

In materials science research, powder metallurgy, or the processing of advanced ceramics, even minute, unintended surface reactions can alter the material's properties and invalidate results.

Atmosphere control eliminates this variable. It ensures that the changes observed in a material are due to the heat treatment alone, not due to random reactions with ambient air.

Understanding the Trade-offs

While powerful, atmosphere control is not a universal requirement. Its inclusion introduces complexity and cost that must be weighed against the needs of your application.

Increased Cost and Complexity

A furnace equipped for atmosphere control requires gas delivery systems, flow meters, safety interlocks, and potentially a vacuum pump. This increases the initial purchase price and the operational complexity compared to a standard air-atmosphere furnace.

Ongoing Operational Costs

Process gases like high-purity nitrogen and argon are a consumable cost. The total expense will depend on the frequency of use, the volume of the furnace chamber, and the required flow rates for your process.

Not Always Necessary

For many applications, atmosphere control is overkill. Processes like ashing samples, simple tempering of non-critical parts, or firing certain ceramics do not require a controlled atmosphere. In these cases, a standard, high-quality muffle furnace is the more practical and economical choice.

Making the Right Choice for Your Goal

The decision to invest in atmosphere control hinges entirely on the requirements of your process and the materials you work with.

- If your primary focus is ashing, binder burnout, or basic heat treatment where surface oxidation is acceptable: A standard muffle furnace without atmosphere control is sufficient and more cost-effective.

- If your primary focus is processing oxygen-sensitive metals (e.g., bright annealing steel, copper, or titanium alloys): An inert gas atmosphere is essential to prevent scaling and preserve the material's surface integrity.

- If your primary focus is advanced surface engineering or materials research: A furnace with precise gas mixing capabilities is required to actively control the chemical reactions and achieve specific material properties.

Ultimately, selecting a furnace with atmosphere control is a strategic decision to gain absolute command over your material's final properties.

Summary Table:

| Benefit | Description |

|---|---|

| Prevents Oxidation | Uses inert gases like nitrogen or argon to stop unwanted reactions, preserving material integrity. |

| Enables Surface Modification | Allows processes like carburizing or nitriding to harden surfaces and improve material properties. |

| Ensures Purity | Maintains a controlled environment for sensitive materials, ensuring accurate research and processing. |

| Key Applications | Ideal for heat-treating metals, advanced ceramics, and materials science research. |

Ready to elevate your laboratory's capabilities with advanced high-temperature furnace solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with cutting-edge equipment, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements, helping you achieve superior material processing outcomes. Don't settle for basic heating—gain absolute command over your processes. Contact us today to discuss how our tailored solutions can benefit your specific applications!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How does a chemically inert atmosphere function in a furnace? Prevent Oxidation and Ensure Material Purity

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- How does an inert atmosphere prevent oxidation? Shield Materials from Oxygen Damage

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment