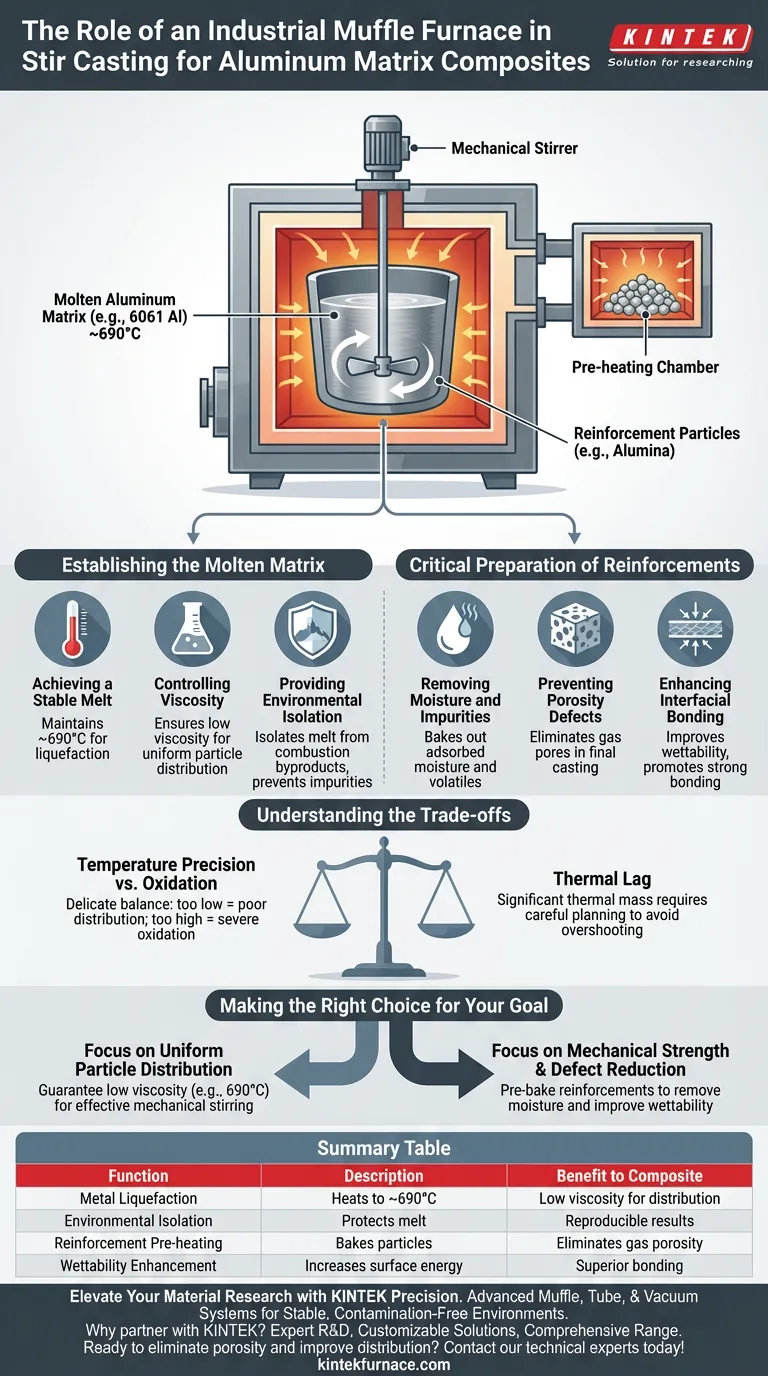

The primary function of an industrial muffle furnace in the stir casting process is to act as the central melting unit, creating the necessary liquid phase for the composite. specifically, it heats the matrix metal (such as 6061 aluminum alloy) to a controlled temperature, commonly around 690°C, to ensure it reaches a fully liquefied, low-viscosity state. This state is essential to allow the mechanical stirrer to uniformly distribute reinforcement particles throughout the melt.

Core Takeaway The muffle furnace is the foundational tool for stir casting, responsible for transforming the aluminum alloy into a receptive liquid matrix. Beyond simple melting, it provides the precise thermal control required to pre-treat reinforcement particles, ensuring strong interfacial bonding and preventing defect formation in the final composite.

Establishing the Molten Matrix

Achieving a Stable Melt

The muffle furnace’s most immediate role is providing a stable, high-temperature environment to liquefy the base metal. For aluminum matrix composites, this often involves maintaining temperatures like 690°C.

Controlling Viscosity

Liquefaction alone is not enough; the melt must have low viscosity. The furnace ensures the aluminum is fluid enough to accept the introduction of reinforcement particles without immediate clumping or segregation.

Providing Environmental Isolation

A key advantage of the muffle design is the isolation of the melt from combustion byproducts. This contamination-free environment allows researchers to generate reproducible results without introducing impurities that could degrade the alloy's chemistry.

Critical Preparation of Reinforcements

Removing Moisture and Impurities

While the primary reference highlights melting the metal, the furnace is often utilized to pre-bake reinforcement particles (such as alumina) before they are added to the melt. This high-temperature exposure removes adsorbed moisture and volatile impurities from the particle surfaces.

Preventing Porosity Defects

If moisture remains on the particles, it turns into steam upon contact with molten aluminum, creating gas pores in the casting. By using the furnace to pre-treat particles, you eliminate this common source of structural weakness.

Enhancing Interfacial Bonding

Pre-heating the particles in the muffle furnace significantly improves wettability. This ensures that when the ceramic particles enter the molten aluminum, the metal flows over them smoothly, creating a high-quality bond rather than rejecting the particles.

Understanding the Trade-offs

Temperature Precision vs. Oxidation

While the furnace provides heat, maintaining the exact temperature is a delicate balance. If the temperature is too low, the viscosity remains high, leading to poor particle distribution. However, if the temperature is excessive, it can lead to severe oxidation of the aluminum melt or unwanted chemical reactions between the matrix and the reinforcement.

Thermal Lag

Industrial muffle furnaces are robust but can have significant thermal mass. This means they may react slowly to temperature set-point changes, requiring careful planning to avoid overshooting target temperatures during the delicate mixing phase.

Making the Right Choice for Your Goal

To maximize the quality of your aluminum matrix composites, consider how you utilize the furnace for both phases of the material:

- If your primary focus is Uniform Particle Distribution: Ensure the furnace is set to a temperature that guarantees low viscosity (e.g., 690°C for 6061 Al) to facilitate mechanical stirring.

- If your primary focus is Mechanical Strength and Defect Reduction: Use the furnace to pre-bake your reinforcement particles to remove moisture and improve wettability before adding them to the melt.

Success in stir casting relies not just on melting the metal, but on using thermal precision to prepare both the liquid matrix and the solid reinforcements for integration.

Summary Table:

| Function | Description | Benefit to Composite |

|---|---|---|

| Metal Liquefaction | Heats aluminum alloy (e.g., 6061 Al) to ~690°C. | Ensures low viscosity for uniform particle distribution. |

| Environmental Isolation | Protects melt from combustion byproducts. | Prevents chemical impurities and ensures reproducible results. |

| Reinforcement Pre-heating | Bakes ceramic particles to remove moisture/volatiles. | Eliminates gas porosity and structural weaknesses. |

| Wettability Enhancement | Increases particle surface energy via heat. | Promotes superior interfacial bonding between matrix and reinforcement. |

Elevate Your Material Research with KINTEK Precision

Achieving the perfect aluminum matrix composite requires more than just heat—it requires thermal precision and environmental control. KINTEK’s advanced range of muffle, tube, and vacuum systems are engineered to provide the stable, contamination-free environment necessary for high-quality stir casting.

Why partner with KINTEK?

- Expert R&D & Manufacturing: Our systems are built for consistency and long-term durability in lab and industrial settings.

- Customizable Solutions: Whether you need specific atmosphere control or high-mass heating, our furnaces are tailored to your unique composite requirements.

- Comprehensive Range: From Rotary and CVD systems to high-temperature Muffle furnaces, we support every stage of advanced material synthesis.

Ready to eliminate porosity and improve particle distribution in your composites? Contact our technical experts today to find the perfect thermal solution for your lab.

Visual Guide

References

- C P Vandana, Q. Mohammad. Revolutionizing Aluminum-Based Composites: Enhancing Strength with Eggshell and Bagasse Ash Reinforcement via Stir Casting. DOI: 10.1051/e3sconf/202450701052

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why is a muffle furnace essential in research laboratories? Unlock Precision Heating for Accurate Results

- Why is a 550°C environment in a Muffle Furnace necessary for AC/ZnO nanocomposites? Achieve Optimal Crystallinity

- How are high-temperature muffle furnaces and AAS utilized in lipstick heavy metal detection for consumer safety?

- What is the specific function of a muffle furnace in rice straw biochar production? Key Pyrolysis Roles Explained

- Which industries utilize Box Furnaces? The Essential Tool for Industrial Heat Treatment

- What is the role of a laboratory high-temperature muffle furnace in the pretreatment of peat clay? Unlock Reactivity

- What experimental conditions does a programmable muffle furnace provide for fire-retardant coatings? Lab Precision

- What advanced features do muffle furnaces include? Boost Precision and Safety in Your Lab