The primary function of a muffle furnace in rice straw biochar production is to create a controlled, oxygen-limited environment for pyrolysis. By isolating the biomass from direct flame and external air, the furnace heats the rice straw—typically to around 600°C—to thermally decompose organic matter without burning it to ash. This process converts the raw straw into a stable, porous carbon material with high pH and high cation content.

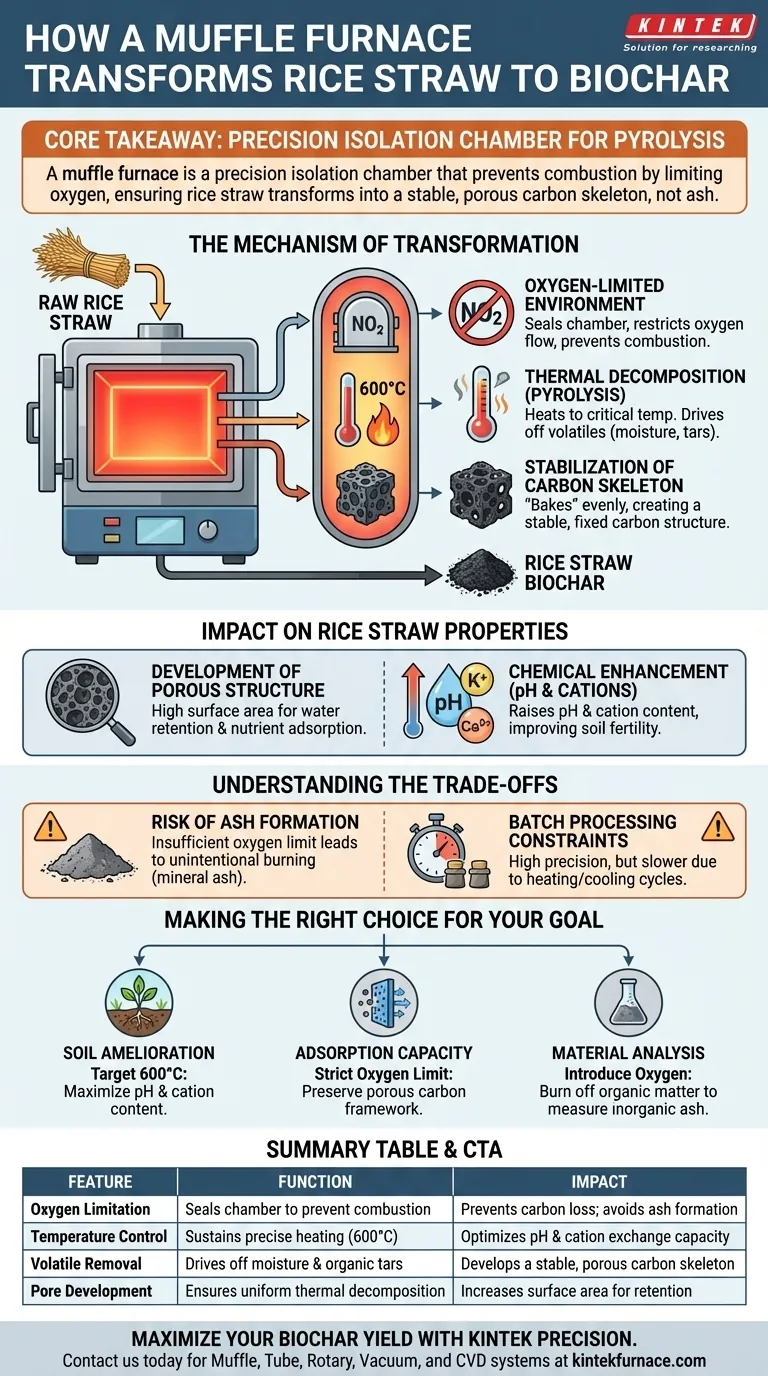

Core Takeaway A muffle furnace is not just a heater; it is a precision isolation chamber that facilitates pyrolysis. Its critical role is to prevent combustion by limiting oxygen, ensuring the rice straw transforms into a chemically stable carbon skeleton with a porous structure rather than degrading into mineral ash.

The Mechanism of Transformation

Creating an Oxygen-Limited Environment

The defining feature of biochar production is the absence of open combustion. A muffle furnace is designed to seal the heating chamber from the outside atmosphere. This "muffled" environment restricts oxygen flow, preventing the rice straw from catching fire and turning into ash, which would occur in an open kiln.

Thermal Decomposition (Pyrolysis)

Once the oxygen is restricted, the furnace drives the temperature up to critical levels, specifically 600°C for optimal rice straw biochar. At this temperature, the biomass undergoes thermochemical decomposition. The heat breaks down the complex organic compounds in the straw, driving off volatiles like moisture and tars.

Stabilization of the Carbon Skeleton

As volatile components evaporate, what remains is a fixed carbon structure. The muffle furnace ensures this structure is "baked" evenly. This results in a stable material that resists biological decay, making it suitable for long-term soil applications.

Impact on Rice Straw Properties

Development of Porous Structure

The primary reference indicates that the specific conditions provided by the furnace (600°C) yield a "well-developed porous structure." This porosity is essential for the biochar's utility, as it increases surface area. A high surface area allows the biochar to retain water and adsorb nutrients in soil environments.

Chemical Enhancement (pH and Cations)

The controlled heating directly alters the chemical profile of the rice straw. Processing at 600°C significantly raises the pH of the final material. It also results in high cation content, which improves the biochar's ability to exchange ions and improve soil fertility.

Understanding the Trade-offs

The Risk of Ash Formation

It is critical to distinguish between biochar production and ash determination. As noted in supplementary data, muffle furnaces are also used to determine ash content by subjecting samples to complete combustion (e.g., 550°C for 4 hours with oxygen). If the environment inside your furnace is not sufficiently oxygen-limited during production, you will unintentionally burn off the carbon and produce mineral ash instead of biochar.

Batch Processing Constraints

A muffle furnace is typically a batch-processing tool, not a continuous flow system. It offers high precision and control for laboratory-scale research or small-batch production. However, for industrial-scale production, this method may be too slow due to the heating and cooling cycles required for each batch.

Making the Right Choice for Your Goal

To maximize the utility of your muffle furnace for rice straw biochar, consider your end goals:

- If your primary focus is Soil Amelioration: Target a temperature of 600°C to maximize pH levels and cation content, ensuring the biochar can effectively neutralize acidic soils.

- If your primary focus is Adsorption Capacity: Ensure the oxygen limitation is strict to preserve the porous carbon framework; accidental oxidation will degrade the pore structure necessary for trapping contaminants.

- If your primary focus is Material Analysis: You can intentionally introduce oxygen and extend heating times to burn off organic matter completely, allowing you to measure the inorganic ash content of the straw.

The muffle furnace is the gatekeeper between simple burning and complex chemical engineering, turning agricultural waste into a valuable carbon resource.

Summary Table:

| Feature | Function in Biochar Production | Impact on Rice Straw Biochar |

|---|---|---|

| Oxygen Limitation | Seals chamber to prevent combustion | Prevents carbon loss; avoids ash formation |

| Temperature Control | Sustains precise heating (typically 600°C) | Optimizes pH and cation exchange capacity |

| Volatile Removal | Drives off moisture and organic tars | Develops a stable, porous carbon skeleton |

| Pore Development | Ensures uniform thermal decomposition | Increases surface area for nutrient/water retention |

Maximize Your Biochar Yield with KINTEK Precision

Don't let your valuable biomass turn to ash. KINTEK’s advanced laboratory solutions provide the precision thermal control needed to engineer high-performance biochar. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to your specific research or production requirements.

Whether you are optimizing soil fertility or enhancing adsorption capacity, our high-temperature furnaces deliver the oxygen-limited environment essential for superior results. Contact us today to find the perfect furnace for your lab!

Visual Guide

References

- Ying‐Ren Lai, Shan‐Li Wang. Effects of Biochar on the Temporal Dynamics and Vertical Distribution of Iron and Phosphorus Under Soil Submergence. DOI: 10.3390/agronomy15061394

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What should be evaluated regarding the heating elements in a muffle furnace? Ensure Optimal Performance and Longevity

- What are the cost differences between industrial muffle furnaces and drying ovens? Understand the Price Gap and Choose Wisely

- What role does a Box Furnace play during the oxidative stabilization of nanofibers? Essential Chemical Transformation

- What role does a high-temperature muffle furnace play in STFO synthesis? Achieve Pure Perovskite Results

- What are the primary functions of industrial high-temperature muffle or tube furnaces in the sintering of PCEC?

- How is a box furnace used in sintering of metal powders? Achieve Dense, High-Strength Metal Parts

- Why is a laboratory box resistance furnace or muffle furnace necessary for the synthesis of the MgCo2O4 spinel structure?

- Why might crucible furnaces be inefficient? High Operating Costs from Low Thermal Efficiency