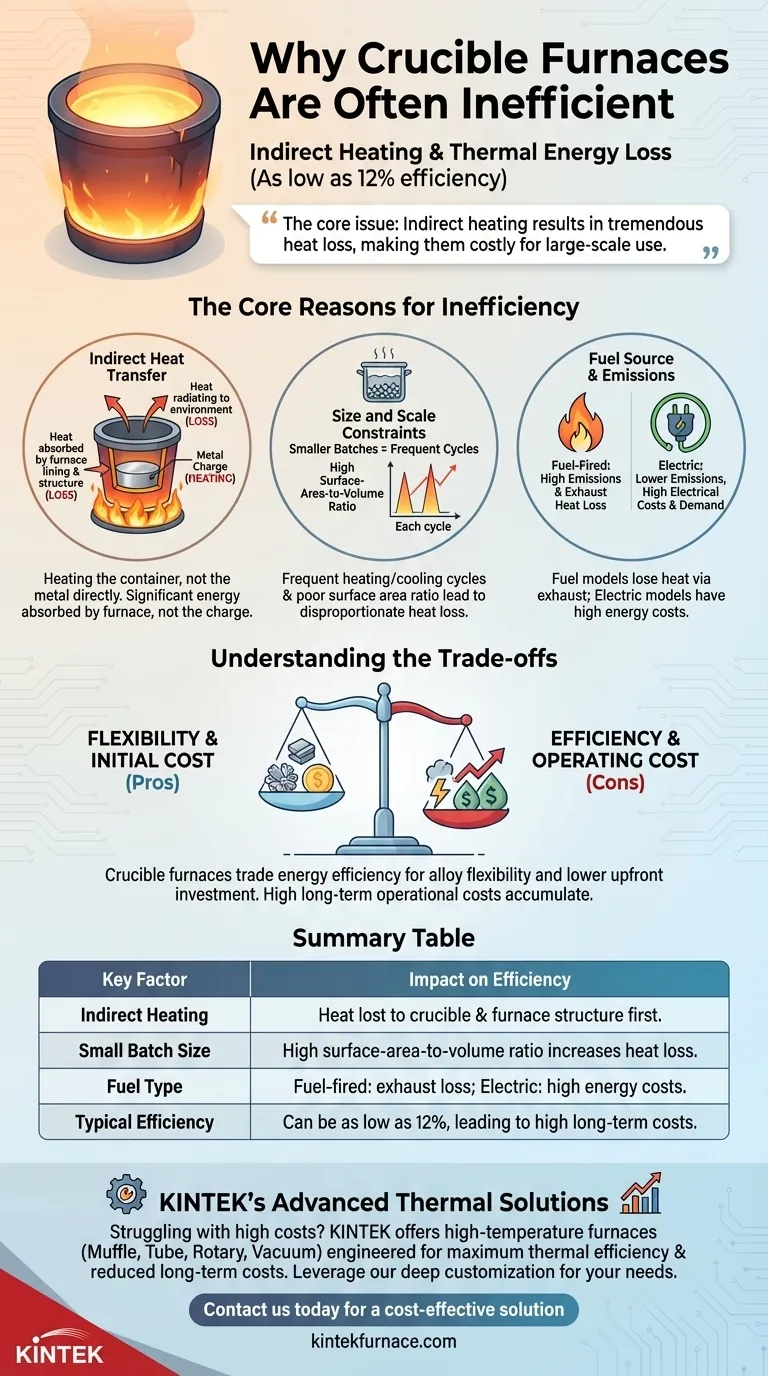

Crucible furnaces are often inefficient due to their fundamental design, which involves heating a container (the crucible) rather than the metal directly. This indirect heating process results in significant thermal energy loss to the furnace structure and the surrounding environment, with some models operating at an efficiency as low as 12%, driving up long-term operational costs.

The core issue is that crucible furnaces lose a tremendous amount of heat by design. This inherent inefficiency, combined with size limitations and fuel source trade-offs, makes them costly to operate for anything other than small-scale or specialized applications.

The Core Reasons for Inefficiency

To understand the cost of running a crucible furnace, we must first examine the sources of its energy waste. The inefficiency is not a single flaw but a combination of design principles and operational realities.

Fundamental Design and Heat Transfer

A crucible furnace works by heating the outside of a pot, and that heat must then conduct through the crucible's walls to melt the metal inside. This indirect process is the primary source of inefficiency.

A significant portion of the energy from the burners or heating elements is absorbed by the furnace lining and structure, not the metal charge. More heat is lost through the flue (in fuel-fired models) and radiated from the furnace's outer shell into the workshop.

Size and Scale Constraints

Crucible furnaces are not designed for large-scale, high-volume production. This size limitation directly contributes to poor energy performance.

Smaller melt batches mean the furnace must be heated and cooled more frequently, wasting energy during each cycle. The smaller size also creates an unfavorable surface-area-to-volume ratio, leading to disproportionately high heat loss compared to larger furnace types.

Fuel Source and Emissions

The choice of energy source introduces its own set of inefficiencies and costs. Traditional fuel-fired furnaces are notorious for high emissions and heat loss through exhaust gases.

While modern electric crucible furnaces nearly eliminate emissions at the point of use, they can be very expensive to operate. The cost of electricity can make them economically inefficient, even if they are thermally cleaner and more controlled.

Understanding the Trade-offs

The "inefficiency" of a crucible furnace is often a known compromise made to gain other advantages. Choosing the right furnace requires weighing energy performance against your specific operational needs.

Efficiency vs. Flexibility

Crucible furnaces offer excellent flexibility. They are ideal for melting a wide variety of alloys in smaller batches without cross-contamination, which is critical for specialty foundries, labs, and artisan workshops.

This versatility is often worth the trade-off in fuel or electricity costs, as other furnace types that are more efficient are also far more restrictive in the alloys they can handle.

Initial Cost vs. Operating Cost

Crucible furnaces typically have a lower initial purchase and installation cost compared to more efficient technologies like induction furnaces. This makes them an accessible entry point for smaller operations.

However, this lower upfront investment is balanced by higher long-term operating costs. The expense of wasted energy, as noted by efficiency ratings as low as 12%, will accumulate over the life of the furnace.

Emissions vs. Electrical Load

While an electric crucible furnace solves the problem of high emissions from traditional models, it creates a new challenge: high electrical demand.

This not only impacts your utility bill but may also require significant upgrades to your facility's electrical infrastructure, adding a hidden cost to the "cleaner" option.

Making the Right Choice for Your Operation

Understanding these factors empowers you to look beyond a simple efficiency number and select a furnace that aligns with your business goals.

- If your primary focus is low-volume, high-variety melting: The flexibility of a crucible furnace may outweigh its low energy efficiency, making it a viable choice.

- If your primary focus is large-scale, continuous production: The poor efficiency and high operating costs of a crucible furnace make it unsuitable; a more efficient furnace type is necessary.

- If your primary focus is environmental compliance and precision: An electric crucible furnace is superior to a fuel-fired one, but you must budget for the high electricity costs.

Ultimately, recognizing that a crucible furnace trades energy efficiency for flexibility and lower initial cost is the key to making a sound investment.

Summary Table:

| Key Factor | Impact on Efficiency |

|---|---|

| Indirect Heating | Heat is lost to the crucible and furnace structure first. |

| Small Batch Size | High surface-area-to-volume ratio increases heat loss. |

| Fuel Type | Fuel-fired models lose heat via exhaust; electric models have high energy costs. |

| Typical Efficiency | Can be as low as 12%, leading to high long-term operational costs. |

Struggling with high operating costs from an inefficient furnace?

While crucible furnaces offer flexibility for small-scale melting, their inherent inefficiency can severely impact your bottom line. For operations prioritizing energy efficiency and larger-scale production, a more advanced thermal solution is key.

KINTEK's advanced high-temperature furnaces are engineered to maximize thermal efficiency and reduce your long-term costs. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories and foundries with robust alternatives. Our product line, including Muffle, Tube, Rotary, and Vacuum & Atmosphere Furnaces, is designed for superior heat transfer and control.

Our strong deep customization capability allows us to precisely meet your unique production requirements, helping you move beyond the limitations of traditional crucible designs.

Contact us today to discuss a more efficient and cost-effective heating solution for your operation.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing