In short, a box furnace is used in the sintering of metal powders by providing a highly controlled, high-temperature environment. It heats the compacted powder, known as a "green part," to a precise temperature just below its melting point, causing the individual metal particles to fuse together and form a solid, dense component. The furnace's critical function is to manage both temperature and atmosphere to achieve the desired material properties.

The effectiveness of a box furnace for sintering is not just about reaching high temperatures. Its true value lies in its ability to precisely control the internal atmosphere, which is essential for preventing oxidation and other unwanted chemical reactions that would compromise the final metal part's integrity.

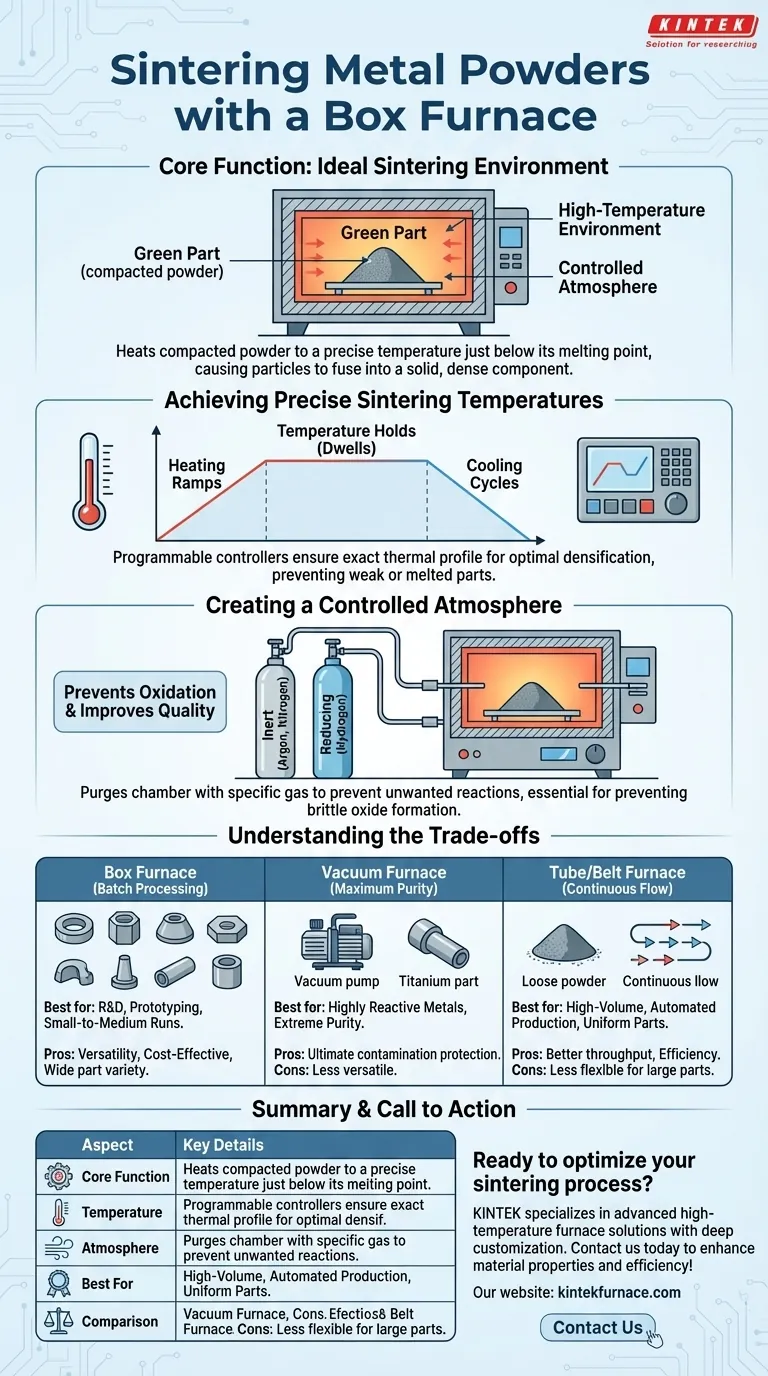

The Core Function: Creating the Ideal Sintering Environment

Sintering is a delicate thermal process. The goal is atomic diffusion between particles, not melting. A box furnace provides the stable, uniform, and controlled environment required to successfully bond metal powders into a coherent mass.

Achieving Precise Sintering Temperatures

Sintering occurs within a very specific temperature window. Too low, and the particles won't bond effectively, resulting in a weak part. Too high, and the part may melt, sag, or lose its shape.

A box furnace uses programmable controllers to execute precise heating ramps, temperature holds (dwells), and cooling cycles, ensuring the material experiences the exact thermal profile needed for optimal densification.

Creating a Controlled Atmosphere

This is arguably the most critical parameter for sintering metals. Heating most metals in the presence of air (oxygen) will cause rapid oxidation, forming a brittle oxide layer that prevents proper metallic bonding.

An atmosphere box furnace solves this by allowing the processing chamber to be purged and filled with a specific gas. This prevents unwanted reactions and can even improve the material's surface quality.

Common Atmospheres and Their Purpose

-

Inert Atmosphere (Argon, Nitrogen): These gases are non-reactive. They are used to simply displace oxygen and prevent oxidation from occurring during the heating cycle.

-

Reducing Atmosphere (Hydrogen, Hydrogen/Nitrogen Mix): A reducing atmosphere actively removes surface oxides from the metal particles. This can lead to stronger bonds and a cleaner final product.

Understanding the Trade-offs: Box Furnace vs. Other Methods

While versatile, a box furnace is not the only option for sintering. Understanding its strengths and weaknesses compared to other technologies is key to making an informed decision.

The Box Furnace: Versatility for Batch Processing

A box furnace excels at processing parts in batches. Its simple, enclosed chamber can accommodate a wide variety of part sizes and shapes, making it ideal for research and development, prototyping, and small-to-medium production runs.

The Vacuum Furnace: For Maximum Purity

For highly reactive metals like titanium or for applications demanding extreme purity, a vacuum furnace is often superior. By removing virtually all gases from the chamber, it provides the ultimate protection against contamination and oxidation, something an atmosphere purge in a box furnace cannot fully guarantee.

The Tube Furnace: For Uniformity and Continuous Flow

For processing loose powders or small, uniform parts, a rotary tube furnace can offer better heating uniformity by tumbling the material as it heats. Other continuous furnaces, like belt furnaces, are better suited for high-volume, automated production lines where parts move continuously through different heat zones.

Making the Right Choice for Your Goal

The best sintering method depends entirely on your material, production volume, and desired final properties. Use these guidelines to inform your decision.

- If your primary focus is R&D, process development, or flexible batch production: An atmosphere box furnace offers an excellent balance of control, versatility, and cost-effectiveness.

- If your primary focus is sintering highly reactive metals or achieving maximum purity: A dedicated vacuum furnace is the necessary choice to eliminate atmospheric contamination.

- If your primary focus is high-volume, continuous manufacturing of a single part type: A specialized continuous belt or rotary tube furnace will deliver better throughput and efficiency.

Ultimately, matching the furnace technology to your specific material and performance requirements is the key to successful sintering.

Summary Table:

| Aspect | Key Details |

|---|---|

| Core Function | Provides controlled high-temperature environment to fuse metal powders into solid parts without melting. |

| Temperature Control | Uses programmable heating ramps, dwells, and cooling cycles for optimal densification. |

| Atmosphere Control | Prevents oxidation with inert (e.g., Argon, Nitrogen) or reducing (e.g., Hydrogen) gases. |

| Best For | R&D, prototyping, and batch production of various part sizes and shapes. |

| Comparison | More versatile than vacuum furnaces for general use; less suited for high-volume continuous production. |

Ready to optimize your sintering process? KINTEK specializes in advanced high-temperature furnace solutions tailored for diverse laboratory needs. Leveraging our exceptional R&D and in-house manufacturing, we offer products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization to meet your unique experimental requirements. Contact us today to discuss how our furnaces can enhance your material properties and production efficiency!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- Can box type high-temperature resistance furnaces control the atmosphere? Unlock Precision in Material Processing

- How does a mixed gas flow control system maintain stability during high-temperature nitriding? Precision Gas Ratios