In short, a muffle furnace is essential in research because it provides an exceptionally hot, highly uniform, and contaminant-free environment for testing and transforming materials. This allows for a level of accuracy and repeatability in high-temperature experiments—from chemical analysis to metallurgy—that standard ovens or open-flame heating simply cannot match.

The true value of a muffle furnace isn't just its ability to reach high temperatures, but its core design feature: the muffle. This internal chamber isolates the sample from the heating elements, ensuring that any observed change is a direct result of controlled heat, not a reaction with fuel byproducts or electrical interference.

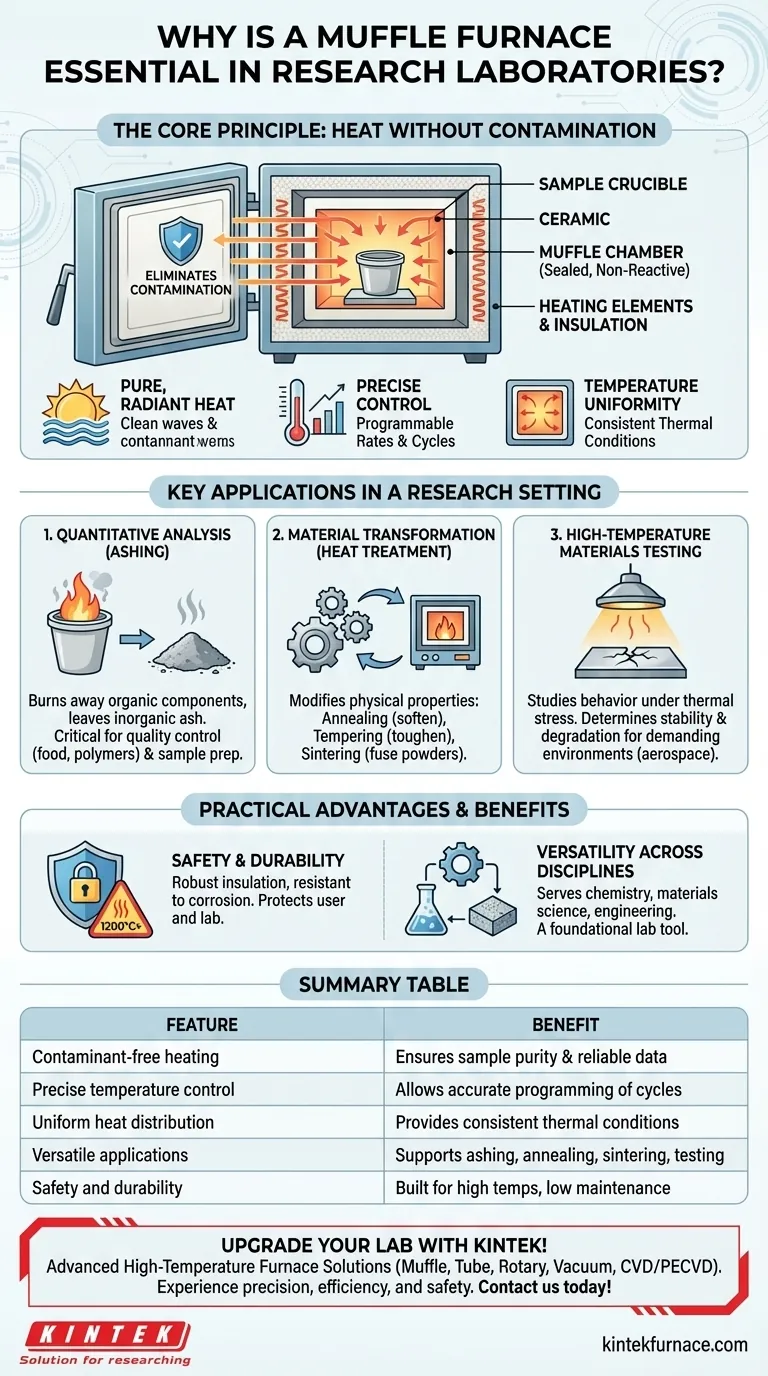

The Core Principle: Heat Without Contamination

A muffle furnace operates on a simple but critical principle that makes it indispensable for scientific work. It delivers pure, radiant heat in a perfectly controlled setting.

What Defines a "Muffle"?

The term "muffle" refers to the sealed inner chamber made of a high-temperature, non-reactive material, typically a ceramic.

This chamber contains the sample and is positioned inside a larger, insulated cabinet where the actual heating elements are located.

This "box-within-a-box" design prevents any direct contact between the sample and the heat source, eliminating the risk of contamination that would invalidate experimental results.

The Importance of Precision and Uniformity

Beyond purity, a muffle furnace provides exceptional temperature control. Researchers can program precise heating rates, soaking times at a specific temperature, and controlled cooling cycles.

This level of control is vital for processes like heat-treating metals, where slight deviations can drastically alter the final material's properties.

Furthermore, these furnaces are engineered for temperature uniformity, ensuring the entire sample experiences the exact same thermal conditions, which is critical for consistent and reliable data.

Key Applications in a Research Setting

The unique capabilities of a muffle furnace make it a versatile workhorse across numerous scientific disciplines. Its applications generally fall into three main categories.

1. Quantitative Analysis and Sample Preparation

The most common analytical use is ashing. This process involves heating a sample to burn away all organic and volatile components, leaving only the inorganic, non-combustible ash.

This is critical for determining the ash content in materials like food, polymers, coal, and plastics, which is a key metric for quality control and material characterization.

It is also used to prepare samples for further elemental analysis by cleanly removing the organic matrix.

2. Material Transformation and Heat Treatment

Muffle furnaces are central to metallurgy and materials science for modifying the physical properties of materials.

Common processes include annealing (softening metal), tempering (increasing toughness), and quenching (rapidly cooling to harden).

They are also used for sintering, a process that uses heat to fuse fine powders into a solid, cohesive object without melting it.

3. High-Temperature Materials Testing

Researchers use muffle furnaces to study how materials behave under extreme thermal stress.

By exposing polymers, plastics, or composites to high temperatures, scientists can determine their thermal stability, degradation points, and overall durability. This data is essential for developing materials used in demanding environments like aerospace or automotive engineering.

Understanding the Practical Advantages

Beyond its core scientific function, the design of a muffle furnace offers practical benefits that make it a laboratory staple.

Safety and Durability

These furnaces are built to safely contain temperatures that can exceed 1200°C (2192°F). Their robust insulation and durable construction protect both the user and the lab environment.

The internal muffle is made of materials resistant to oxidation and corrosion, ensuring a long operational life with relatively low maintenance, even when handling reactive samples.

Versatility Across Disciplines

A single muffle furnace can serve the needs of a wide range of departments. Its utility in chemistry (for ashing), materials science (for heat treatment), and engineering (for durability testing) makes it a foundational piece of capital equipment.

Making the Right Choice for Your Research

While all muffle furnaces provide controlled heat, selecting the right model depends entirely on your primary application.

- If your primary focus is quantitative analysis (e.g., ashing): You need a furnace with excellent air exchange capabilities to ensure complete combustion and precise temperature control to prevent the loss of volatile inorganic compounds.

- If your primary focus is materials science (e.g., metallurgy): Prioritize a model with exceptional temperature uniformity and the ability to program complex, multi-stage heating and cooling profiles.

- If your primary focus is general-purpose lab use: A durable, reliable model with robust safety features and simple controls will provide the most value for a shared environment.

Ultimately, the muffle furnace is a foundational tool that empowers researchers to reliably control one of the most fundamental variables in science: temperature.

Summary Table:

| Feature | Benefit |

|---|---|

| Contaminant-free heating | Ensures sample purity and reliable data |

| Precise temperature control | Allows accurate programming of heating and cooling cycles |

| Uniform heat distribution | Provides consistent thermal conditions for repeatable results |

| Versatile applications | Supports ashing, annealing, sintering, and materials testing |

| Safety and durability | Built to handle high temperatures with low maintenance |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable, customizable equipment. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all designed to meet your unique experimental needs. Experience enhanced precision, efficiency, and safety—contact us today to discuss how we can support your research goals!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation