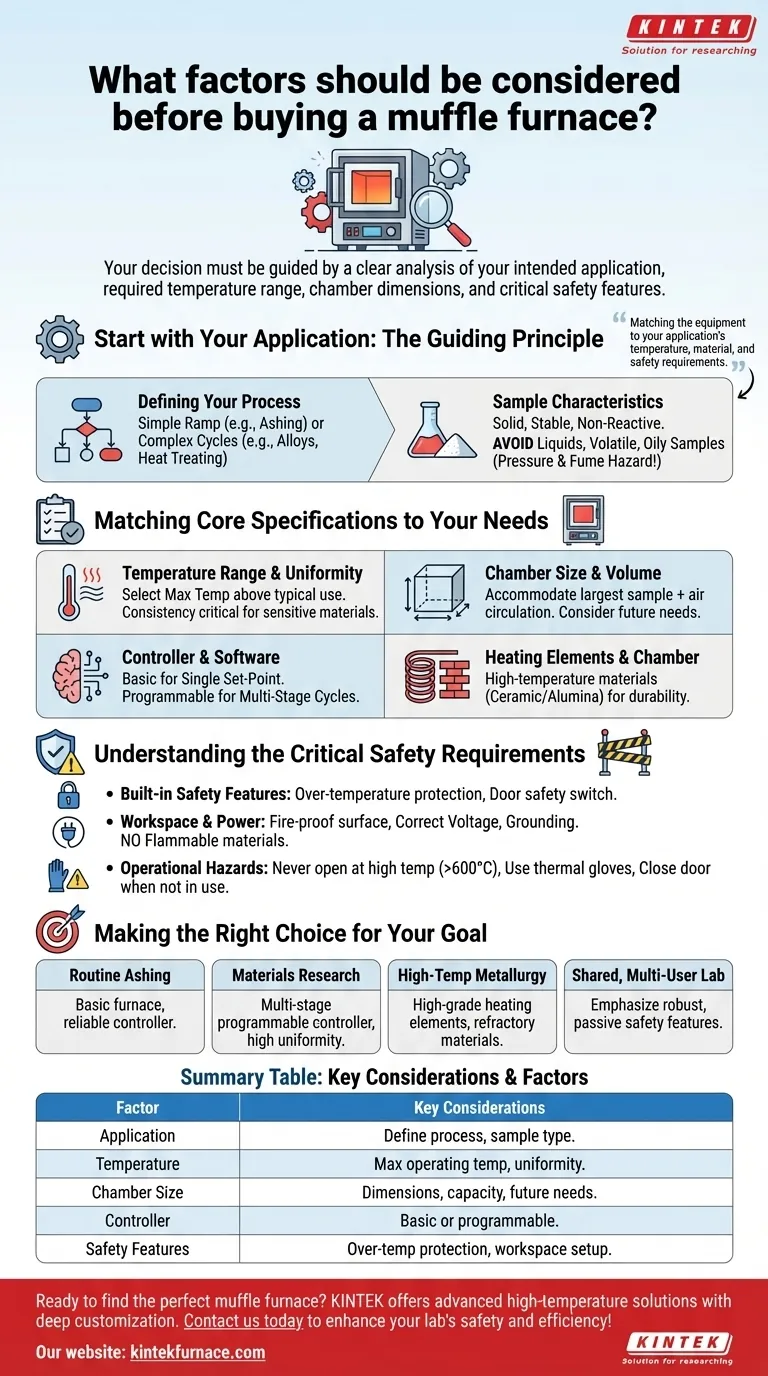

Before purchasing a muffle furnace, your decision must be guided by a clear analysis of your intended application, required temperature range, chamber dimensions, and critical safety features. These core factors ensure the furnace you select is not only effective for your work but also safe for your laboratory environment.

Choosing a muffle furnace is less about finding the "best" specifications and more about precisely matching the equipment to your application's temperature, material, and safety requirements. The right furnace is an extension of your process.

Start with Your Application: The Guiding Principle

Every other decision flows from what you intend to do with the furnace. A furnace идеальный for ashing organic samples is fundamentally different from one designed for creating advanced alloys.

Defining Your Process

Different applications, such as ashing, heat treating, annealing, or materials research, have unique heating and cooling profiles. Clearly define your process to determine the necessary temperature range and control capabilities.

Some processes require a simple ramp to a single temperature, while others, like creating specific metal alloys or ceramics, demand complex, multi-stage programmable cycles.

Understanding Your Sample Characteristics

The nature of your sample is a critical consideration. Most muffle furnaces are designed for thermally stable solids, powders, and other non-reactive materials.

Crucially, you must avoid placing liquids, volatile chemicals, or oily samples directly into a standard furnace. These can generate pressure or release corrosive fumes, creating a significant safety hazard and damaging the furnace interior.

Matching Core Specifications to Your Needs

Once your application is defined, you can assess the technical specifications of the furnace itself.

Temperature Range and Uniformity

The maximum operating temperature is the most important specification. Do not purchase a furnace that will need to run at its absolute maximum temperature for extended periods, as this shortens its lifespan. Select a model with a maximum temperature comfortably above your typical working temperature.

Equally important is temperature uniformity, which is how consistent the temperature证据 is throughout the chamber. For sensitive materials research, high uniformity is critical for repeatable results.

Chamber Size and Volume

The internal chamber dimensions must accommodate your largest sample or crucible, with adequate clearance for air circulation. Consider both your current and future needs to avoid selecting a furnace that is too small for upcoming projects.

The chamber size also relates directly to crucible size and the number of samples you can process in a single batch.

Controller and Software

Furnace controllers range from simple digital units to sophisticated, programmable microprocessors. A basic controller is sufficient for holding a single set-point temperature.

For complex heat-treatment cycles, you will need a programmable controller. This allows you to create and save multi-stage programs with different ramp rates, dwell times, and cooling profiles.

Heating Elements and Chamber Materials

The type of heating element and a chamber's insulating material dictate the furnace's maximum temperature and durability.

High-temperature furnaces often use robust materials like heat-resistant ceramic or alumina fiber to withstand extreme thermal stress and ensure a long operational life.

Understanding the Critical Safety Requirements

A muffle furnace is a powerful piece of equipment that presents significant burn and fire hazards. Evaluating its safety features and your facility's readiness is non-negotiable.

Built-in Safety Features

Look for essential features like over-temperature protection, which automatically shuts down the furnace if it exceeds a preset limit. A door safety switch that cuts power to the heating elements when the door is opened is another vital feature, especially in multi-user environments.

Workspace and Power Infrastructure

The furnace must be placed on a stable, fire-proof surface, such as a cement platform. Your workspace must be free of any flammable or explosive materials.

Ensure your lab has the correct input voltage, proper plugs, and grounding. An incorrect power supply风险 is a fire risk and will damage the equipment.

Operational Hazards to Mitigate

Safe operation is a shared responsibility. Never open the furnace door at extremely high temperatures (e.g., above 600°C) to avoid thermal shock to the chamber and intense radiant heat exposure.

Always wear appropriate thermal gloves when loading or unloading samples. When not in use, the power should be off and the door closed to protect the internal refractory materials from atmospheric moisture.

Making the Right Choice for Your Goal

Your final decision should be a balanced assessment of your primary objective against the furnace's capabilities and cost.

- If your primary focus is routine, single-temperature ashing: A basic furnace with a reliable controller and the appropriate chamber size is a cost-effective and sufficient choice.

- If your primary focus is materials research with complex heat cycles: Prioritize a furnace with a multi-stage programmable controller and documented temperature uniformity.

- If your primary focus is high-temperature metallurgy or ceramics: You must select a furnace specifically designed with high-grade heating elements and refractory materials to handle extreme temperatures.

- If your primary focus is a shared, multi-user lab: Emphasize robust, passive safety features like door interlocks and over-temperature protection to ensure operator safety.

A methodical evaluation of these factors ensures your muffle furnace becomes a reliable, long-term asset, not a source of operational risk.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Application | Define process (e.g., ashing, annealing), sample type (solids, powders) |

| Temperature | Max operating temperature, uniformity for repeatable results |

| Chamber Size | Dimensions for sample capacity, air circulation, future needs |

| Controller | Basic for single set-point or programmable for complex cycles |

| Safety Features | Over-temperature protection, door safety switch, proper workspace setup |

Ready to find the perfect muffle furnace for your lab? KINTEK offers advanced high-temperature solutions, including Muffle, Tube, and Rotary Furnaces, with deep customization to meet your unique experimental needs. Contact us today to enhance your lab's safety and efficiency!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization