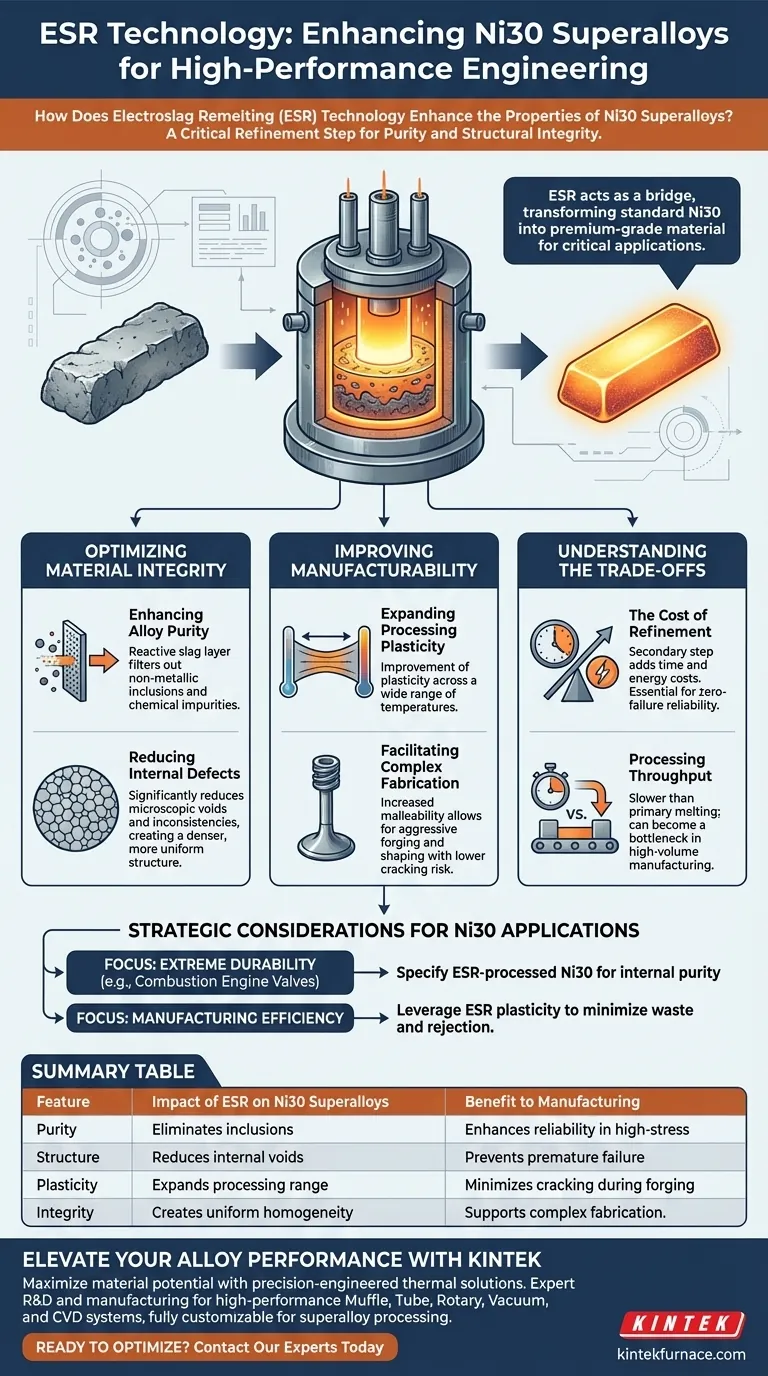

Electroslag Remelting (ESR) technology acts as a critical refinement step that significantly elevates the quality of Ni30 superalloys by targeting material purity and structural integrity. By subjecting the alloy to this secondary processing stage, manufacturers can effectively minimize internal defects and broaden the material's processing plasticity, ensuring it meets the rigorous demands of high-performance engineering.

The core value of ESR lies in its ability to transform a standard Ni30 ingot into a premium-grade material. It serves as the bridge between basic composition and the reliability required for critical applications like internal combustion engine valves.

Optimizing Material Integrity

Enhancing Alloy Purity

The primary function of ESR technology is to optimize the purity of the Ni30 superalloy.

During the remelting process, the alloy passes through a reactive slag layer. This effectively filters out non-metallic inclusions and chemical impurities that typically degrade material performance.

Reducing Internal Defects

Standard casting processes often leave microscopic voids or inconsistencies within an ingot.

ESR significantly reduces these internal material defects, creating a denser and more uniform structure. This structural homogeneity is essential for preventing premature failure under stress.

Improving Manufacturability

Expanding Processing Plasticity

One of the most distinct advantages of ESR for Ni30 is the improvement of processing plasticity.

This enhancement is not limited to a single thermal point; it occurs across a wide range of temperatures.

Facilitating Complex Fabrication

Because the alloy becomes more plastic (malleable) without losing integrity, it is much easier to work with during subsequent manufacturing steps.

This allows for more aggressive forging or shaping operations with a significantly lower risk of cracking, which is vital when producing complex components like engine valves.

Understanding the Trade-offs

The Cost of Refinement

While ESR provides superior material properties, it is a secondary step that adds time and energy costs to the production cycle.

Engineers must weigh these higher processing costs against the necessity for zero-failure reliability. For non-critical components where extreme purity is not required, standard melting may suffice.

Processing Throughput

ESR is a slower, more controlled process compared to primary melting methods.

This can become a bottleneck in high-volume manufacturing environments, requiring careful supply chain planning to match the production rate of these high-grade ingots with demand.

Strategic Considerations for Ni30 Applications

Deciding when to insist on ESR-processed Ni30 depends on the specific demands of your final application.

- If your primary focus is extreme durability: Specify ESR-processed Ni30 to ensure the internal purity required for parts like combustion engine valves that face constant thermal cycling.

- If your primary focus is manufacturing efficiency: Leverage the enhanced plasticity of ESR ingots to minimize material waste and rejection rates during forging or forming operations.

Ultimately, ESR upgrades Ni30 from a standard alloy to a high-performance material capable of enduring the most demanding thermal and mechanical stresses.

Summary Table:

| Feature | Impact of ESR on Ni30 Superalloys | Benefit to Manufacturing |

|---|---|---|

| Purity | Eliminates non-metallic inclusions and impurities | Enhances reliability in high-stress environments |

| Structure | Reduces internal voids and microscopic defects | Prevents premature failure and fatigue |

| Plasticity | Expands processing plasticity across wide temperature ranges | Minimizes cracking during forging and shaping |

| Integrity | Creates a denser, more uniform structural homogeneity | Supports complex fabrication for engine components |

Elevate Your Alloy Performance with KINTEK

Maximize the potential of your materials with precision-engineered thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet the rigorous demands of superalloy processing and refinement.

Whether you are producing high-performance engine valves or advanced aerospace components, our laboratory and industrial furnaces provide the thermal stability and control necessary for superior metallurgical results.

Ready to optimize your high-temperature processes? Contact our engineering experts today to discover how KINTEK can customize a solution for your unique laboratory or production needs.

Visual Guide

References

- Microstructural Evolution and Oxidation Resistance of Fe-30Ni-15Cr Alloy for Internal Combustion Engine Valves Under Long-Term High-Temperature Exposure and Heat Treatment. DOI: 10.3390/met15010061

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why is a constant temperature oven required for CoCrFeNiMn alloy powders? Ensure Superior Defect-Free Deposition

- Why are thin iron sheets placed with iron ore pellet samples? Ensure Data Accuracy in Load Softening Experiments

- What is the catalytic mechanism of methane gas conversion in Ni-Co CNT synthesis? Master Carbon Transformation

- Why is the use of high-temperature furnace systems critical for delta-MnO2 development? Master Atomic Engineering

- Why is a constant temperature drying oven used at 120°C for 16 hours for NiCuCe catalysts? Optimize Site Dispersion

- How does a magnetic stirring hot plate contribute to sol-gel synthesis? Expert Guide to Precursor Thin Film Success

- What is the purpose of using a forced-air drying oven at 100 °C? Optimize Fe3O4@Fe-AC Composite Synthesis

- What are the advantages of using a precision vacuum drying oven? Master Ceramic Powder Treatment with KINTEK