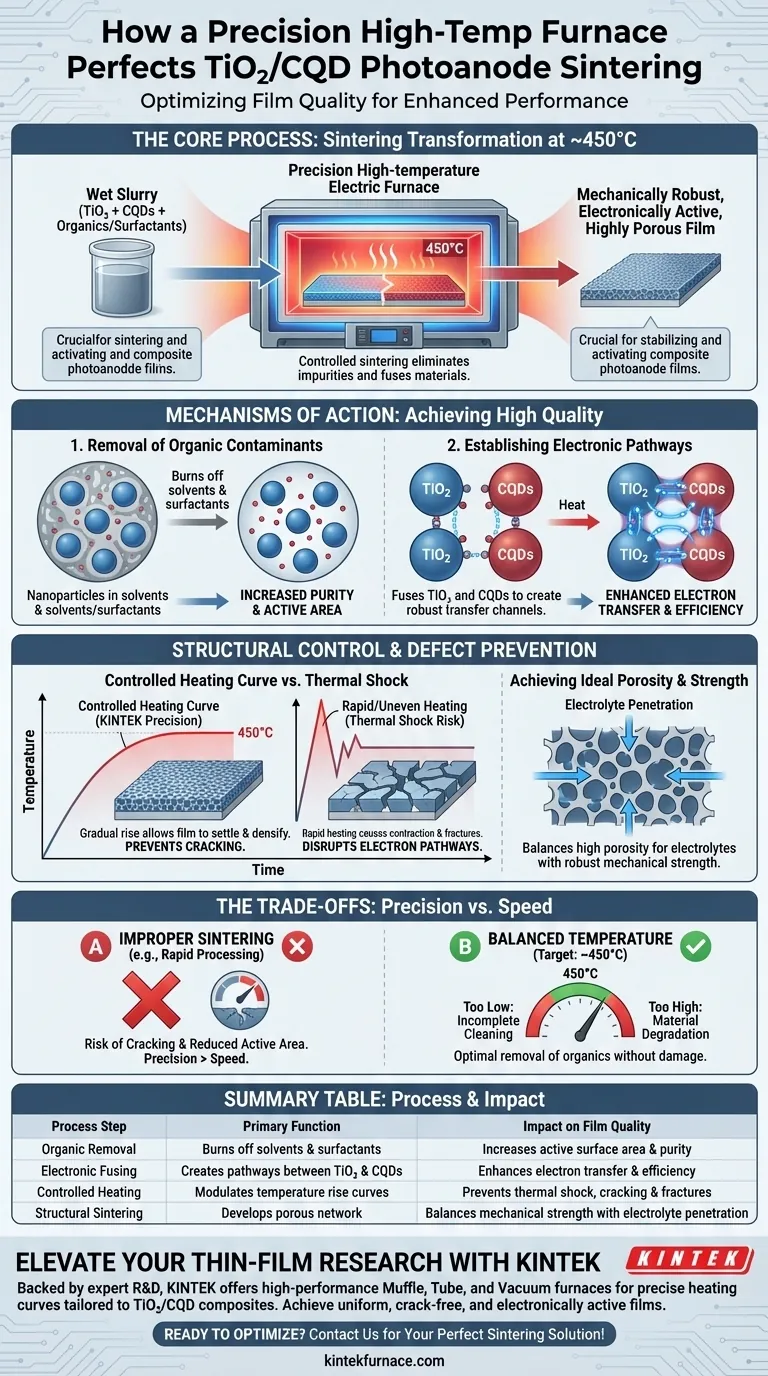

The precision high-temperature electric furnace is the critical instrument for stabilizing and activating composite photoanode films. By subjecting the TiO2 and Carbon Quantum Dot (CQD) mixture to controlled sintering at temperatures around 450°C, the furnace eliminates impurities and fuses the materials. This process transforms a wet slurry into a mechanically robust, electronically active, and highly porous film essential for high performance.

The furnace’s role extends beyond simple drying; it utilizes specific heating curves to prevent structural defects like cracking while establishing vital electronic transfer channels between components.

The Mechanism of Sintering for Composite Films

Removal of Organic Contaminants

The initial slurry used to create the film typically contains organic solvents and surfactants. These additives facilitate application but hinder final performance.

Sintering effectively burns off these organic materials. This purification step is essential for exposing the active surface areas of the nanoparticles.

Establishing Electronic Pathways

For a composite photoanode to function, electrons must move freely between materials. The furnace facilitates tight physical connections between the TiO2 nanoparticles and the CQDs.

This physical fusing creates robust electronic transfer channels. Without this high-temperature treatment, the interface between the materials would remain poor, significantly reducing efficiency.

Structural Control and Defect Prevention

The Importance of Controlled Heating Curves

A common failure point in film preparation is thermal shock. Rapid or uneven heating can cause the film to contract too quickly, leading to fractures.

The precision furnace utilizes a controlled heating curve to modulate the temperature rise. This gradual approach allows the film to settle and densify without developing stress cracks.

Achieving Ideal Porosity and Strength

The goal of sintering is not a solid block, but a porous network. The furnace conditions facilitate the formation of a structure with high porosity.

Simultaneously, the process ensures robust mechanical strength. The result is a film that is porous enough for electrolyte penetration but strong enough to withstand physical handling.

Understanding the Trade-offs

The Risk of Improper Sintering Profiles

While high temperatures are necessary, how you reach them matters. Ignoring the controlled heating curve in favor of rapid processing is a primary cause of film cracking.

A cracked film disrupts the electron pathways and reduces the active surface area. Precision is therefore more valuable than speed in this manufacturing stage.

Balancing Temperature and Material Integrity

The target temperature of 450°C is specific to removing organics without damaging the core materials. Deviating significantly from this standard can lead to incomplete cleaning (if too low) or potential material degradation (if excessive).

Making the Right Choice for Your Goal

To maximize the quality of your TiO2/CQD photoanodes, align your furnace settings with your specific performance objectives:

- If your primary focus is Electrical Efficiency: Ensure the sintering completes the full cycle at 450°C to fully eliminate surfactants and open electronic transfer channels.

- If your primary focus is Mechanical Durability: Prioritize the precision of the heating curve to prevent micro-cracking and ensure a robust, cohesive network.

Controlled sintering is the bridge between a raw chemical mixture and a functional, high-performance energy device.

Summary Table:

| Process Step | Primary Function | Impact on Film Quality |

|---|---|---|

| Organic Removal | Burns off solvents and surfactants | Increases active surface area and purity |

| Electronic Fusing | Creates pathways between TiO2 and CQDs | Enhances electron transfer and efficiency |

| Controlled Heating | Modulates temperature rise curves | Prevents thermal shock, cracking, and fractures |

| Structural Sintering | Develops porous network | Balances mechanical strength with electrolyte penetration |

Elevate Your Thin-Film Research with KINTEK

Precision in sintering is the difference between a failing film and a high-performance energy device. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, and Vacuum furnace systems designed to provide the exact heating curves required for delicate TiO2 and CQD composite materials. Whether you need a standard setup or a fully customizable high-temp furnace tailored to your unique research needs, our team is here to help you achieve uniform, crack-free, and electronically active films every time.

Ready to optimize your photoanode production? Contact us today to find your perfect sintering solution!

Visual Guide

References

- A. C. W. W. M. N. Peshala Koswatta, Atula S. D. Sandanayaka. Boosting Solar Cell Efficiency: Enhancing Dye-Sensitized Solar Cell Performance with Carbon Quantum Dots and Titanium Dioxide Nanostructures from Sri Lankan Ilmenite. DOI: 10.1021/acsomega.5c02272

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the advantages of using an Infrared Rapid Heating Furnace? Capture Transient Atomic Migrations in Steel

- How does chamber size affect muffle furnace selection? Ensure Precision with the Right Fit

- How does a muffle furnace compare to other types of laboratory melting furnaces? Discover the Best Fit for Your Lab

- How does a box muffle furnace determine the final phase and activity of bismuth molybdate? Optimize Your Material Synthesis

- What are the applications of box type resistance furnaces in material research and development? Unlock Precision in Material Synthesis

- What is the purpose of an ashing furnace? Essential for Accurate Ash Content Analysis

- What is the function of a high-precision resistance furnace in the Al-Mg-Si alloy melting process? Achieve 750°C Stability

- What is a muffle furnace and how does it relate to laboratory furnaces? Discover Its Key Benefits for Your Lab