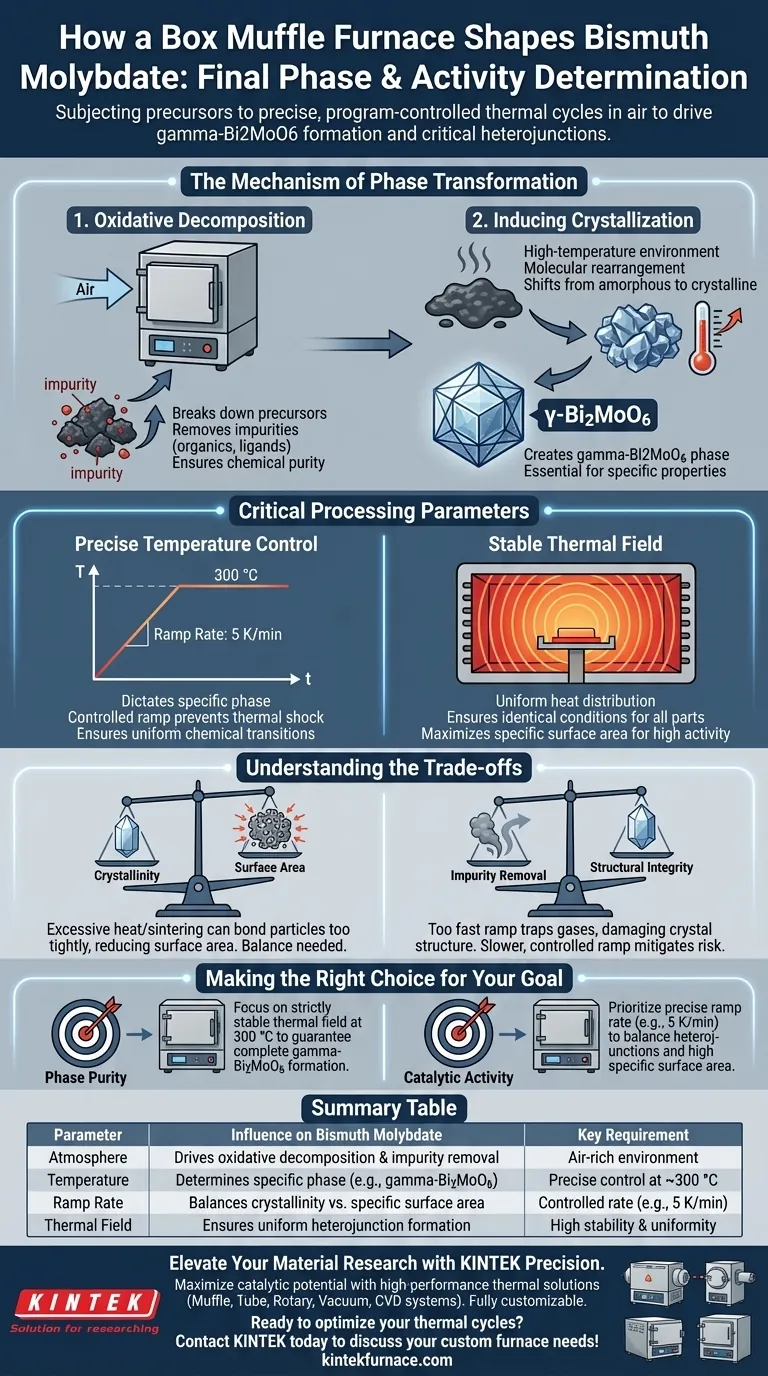

A box muffle furnace determines the final phase and activity of bismuth molybdate materials by subjecting precursors to a precise, program-controlled thermal cycle in an air atmosphere. This environment drives the oxidative decomposition of the precursor and induces crystallization, specifically fostering the formation of the gamma-Bi2MoO6 phase and critical heterojunction components.

By controlling the ramp rate and maintaining a stable thermal field, the furnace transforms amorphous precursors into highly crystalline structures with the specific surface area required for peak catalytic performance.

The Mechanism of Phase Transformation

Oxidative Decomposition

The primary function of the furnace is to facilitate chemical changes that cannot occur at room temperature.

In an air atmosphere, the furnace drives oxidative decomposition, breaking down the precursor materials.

This process effectively removes impurities, ensuring the base material is chemically pure for the subsequent crystallization phase.

Inducing Crystallization

Once the precursors are decomposed, the high-temperature environment forces the remaining material to rearrange at a molecular level.

This transition shifts the material from an amorphous state into a structured, crystalline form.

For bismuth molybdate specifically, this process creates the gamma-Bi2MoO6 phase, which is essential for the material's specific properties.

Critical Processing Parameters

Precise Temperature Control

The specific phase achieved is dictated by the maximum temperature and the rate at which it is applied.

For example, heating at 300 °C with a ramp rate of 5 K/min is a documented protocol for achieving the desired gamma phase.

This controlled ramp rate prevents thermal shock and ensures that the chemical transitions occur uniformly throughout the material.

The Importance of a Stable Thermal Field

Achieving high activity depends heavily on the uniformity of the heat distribution within the furnace.

A stable thermal field ensures that every part of the sample experiences the exact same conditions.

This uniformity is critical for maximizing the specific surface area, a key factor that directly correlates to the material's catalytic activity.

Understanding the Trade-offs

Crystallinity vs. Surface Area

While high temperatures are necessary to induce crystallization and form the correct phase, aggressive heating can have downsides.

Excessive heat or prolonged sintering can lead to particles bonding too tightly, potentially reducing the material's surface area.

You must balance the need for a highly crystalline structure with the need to maintain a high surface area for reactivity.

Impurity Removal vs. Structural Integrity

The furnace is excellent for removing residual ligands or organic surfactants through thermal decomposition.

However, if the ramp rate is too fast, gases from decomposing organics may become trapped or damage the forming crystal structure.

A slower, program-controlled ramp rate helps mitigate this risk but increases overall processing time.

Making the Right Choice for Your Goal

To optimize your bismuth molybdate synthesis, you must tailor the furnace program to your specific performance targets.

- If your primary focus is Phase Purity: Ensure your furnace maintains a strictly stable thermal field at 300 °C to guarantee the complete formation of the gamma-Bi2MoO6 phase without localized inconsistencies.

- If your primary focus is Catalytic Activity: Prioritize a precise ramp rate (e.g., 5 K/min) to balance the development of heterojunction components while preserving a high specific surface area.

Success lies in viewing the furnace not as a simple heater, but as a precision instrument that defines the material's molecular identity.

Summary Table:

| Parameter | Influence on Bismuth Molybdate | Key Requirement |

|---|---|---|

| Atmosphere | Drives oxidative decomposition & impurity removal | Air-rich environment |

| Temperature | Determines specific phase (e.g., gamma-Bi2MoO6) | Precise control at ~300 °C |

| Ramp Rate | Balances crystallinity vs. specific surface area | Controlled rate (e.g., 5 K/min) |

| Thermal Field | Ensures uniform heterojunction formation | High stability & uniformity |

Elevate Your Material Research with KINTEK Precision

Maximize the catalytic potential of your bismuth molybdate synthesis with high-performance thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique laboratory requirements.

Whether you need ultra-stable thermal fields for phase purity or precise ramp control for high-activity catalysts, our lab high-temperature furnaces deliver the accuracy your research demands.

Ready to optimize your thermal cycles? Contact KINTEK today to discuss your custom furnace needs!

Visual Guide

References

- Thi Thanh Hoa Duong, Norbert Steinfeldt. Enhanced Photocatalytic Drug Degradation via Nanoscale Control of Bismuth Molybdate. DOI: 10.1021/acsanm.5c03249

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does the temperature range affect the choice of a muffle furnace? Ensure Precision and Protect Your Materials

- Why is the calcination process in a muffle furnace necessary for preparing bimetallic oxide CuCo2O4?

- How does a laboratory muffle furnace contribute to the transformation of biomass into carbon precursors? Expert Guide

- What should be considered regarding the controller when purchasing a muffle furnace? Choose the Right Controller for Precision

- How do I choose a muffle furnace? A Guide to Matching the Right Furnace to Your Process

- What is the function of a muffle furnace in plant leaf ash analysis? Master Precision Dry Ashing

- Why is chamber size an important consideration when selecting a muffle furnace? Optimize Your Lab's Efficiency and Results

- How does the furnace wall and roof of a box type resistance furnace transfer heat to the metal? Discover the Key Mechanism for Uniform Heating