In short, the chamber size of a muffle furnace is a critical decision because it directly impacts process effectiveness, energy consumption, and operational cost. The chamber must be large enough to not only fit your sample but also to allow for uniform heating, while being small enough to avoid wasting energy and time heating empty space.

Selecting the right chamber size is a balancing act. It is not about the physical dimensions of the furnace itself, but about matching the chamber's usable, uniform heating zone to your specific sample and workload requirements.

The Core Function: Matching Size to Sample

The most fundamental requirement is that your material fits, but the considerations go deeper than simple physical dimensions.

Accommodating Your Workload

The internal chamber dimensions dictate the maximum size and quantity of the samples you can process. You must account for the dimensions of your sample, crucible, or sample tray.

Consider not just a single run but your typical batch size. A slightly larger chamber might significantly improve throughput if you process many small items simultaneously.

The Principle of the "Constant Temperature Zone"

This is the most misunderstood aspect of chamber sizing. The constant temperature zone is the internal volume where the temperature is highly uniform and stable. This zone is always smaller than the physical chamber dimensions.

For successful and repeatable thermal processing, your entire sample must fit comfortably within this uniform zone. Placing a sample in a chamber where it is too close to the walls or door risks uneven heating and inaccurate results.

Ensuring Proper Air Circulation

Effective heating relies on convection and radiation. A chamber that is too tightly packed prevents adequate air circulation around the sample.

This lack of space can create hot spots and cold spots, compromising the uniformity of the process and potentially leading to failed tests or damaged components.

Understanding the Trade-offs of Chamber Sizing

Choosing the wrong size has direct consequences. Both "too large" and "too small" introduce distinct problems that can undermine your work.

The Problem with "Too Small"

The most obvious issue is that your sample simply will not fit. More critically, forcing a sample into a tight space can lead to it touching the heating elements or insulation, causing damage to both the sample and the furnace.

Even if it fits, a sample that is too large for the chamber will almost certainly sit outside the constant temperature zone, guaranteeing non-uniform heating.

The Problem with "Too Large"

A chamber that is excessively large for your typical sample is inefficient. You will pay higher energy costs and experience longer heat-up times as you are heating a significant volume of empty space.

This inefficiency translates directly into higher operational costs and lower productivity, especially in environments where the furnace is used frequently.

Relationship to Other Specifications

Chamber size does not exist in isolation. A larger chamber requires more power to reach and maintain temperature, which may impact the furnace's electrical requirements and the sophistication of the temperature controller needed to manage it.

How to Apply This to Your Project

Base your selection on your specific processing requirements. A clear understanding of your goal will point you to the correct size.

- If your primary focus is precise material testing: Prioritize a chamber where your sample fits entirely within the manufacturer-specified constant temperature zone with room to spare.

- If your primary focus is high-throughput batch processing: Choose a chamber optimized to fit your standard tray or crucible configuration, ensuring adequate space between items for air circulation.

- If your primary focus is maximum energy efficiency: Select the smallest chamber that safely accommodates your largest typical sample within its constant temperature zone.

Choosing the right chamber size ensures your furnace is a precise and efficient tool for your application.

Summary Table:

| Aspect | Key Consideration |

|---|---|

| Sample Fit | Ensures sample and crucible fit without touching walls or elements. |

| Heating Uniformity | Sample must be within the constant temperature zone for accurate results. |

| Air Circulation | Adequate space prevents hot/cold spots and ensures even heating. |

| Energy Efficiency | Right size minimizes energy waste and reduces operational costs. |

| Throughput | Larger chambers allow batch processing but may increase heat-up times. |

Struggling to choose the right muffle furnace for your lab? At KINTEK, we specialize in high-temperature furnace solutions tailored to your unique needs. Leveraging exceptional R&D and in-house manufacturing, we offer advanced products like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization capabilities to precisely match your experimental requirements—ensuring optimal chamber size, energy efficiency, and performance. Contact us today to discuss how we can enhance your laboratory's productivity and accuracy!

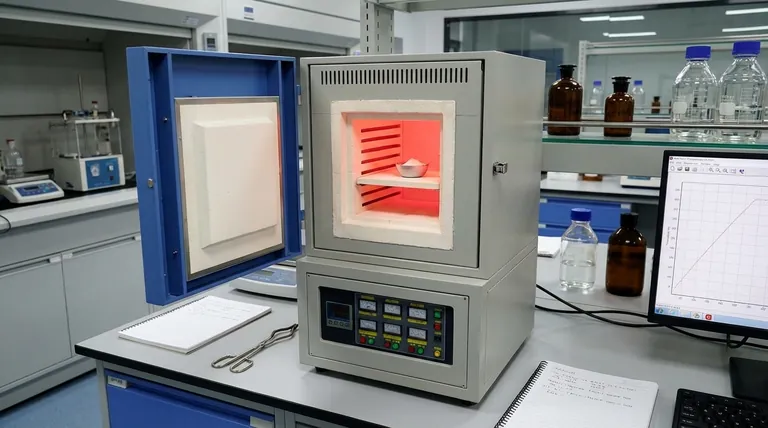

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation