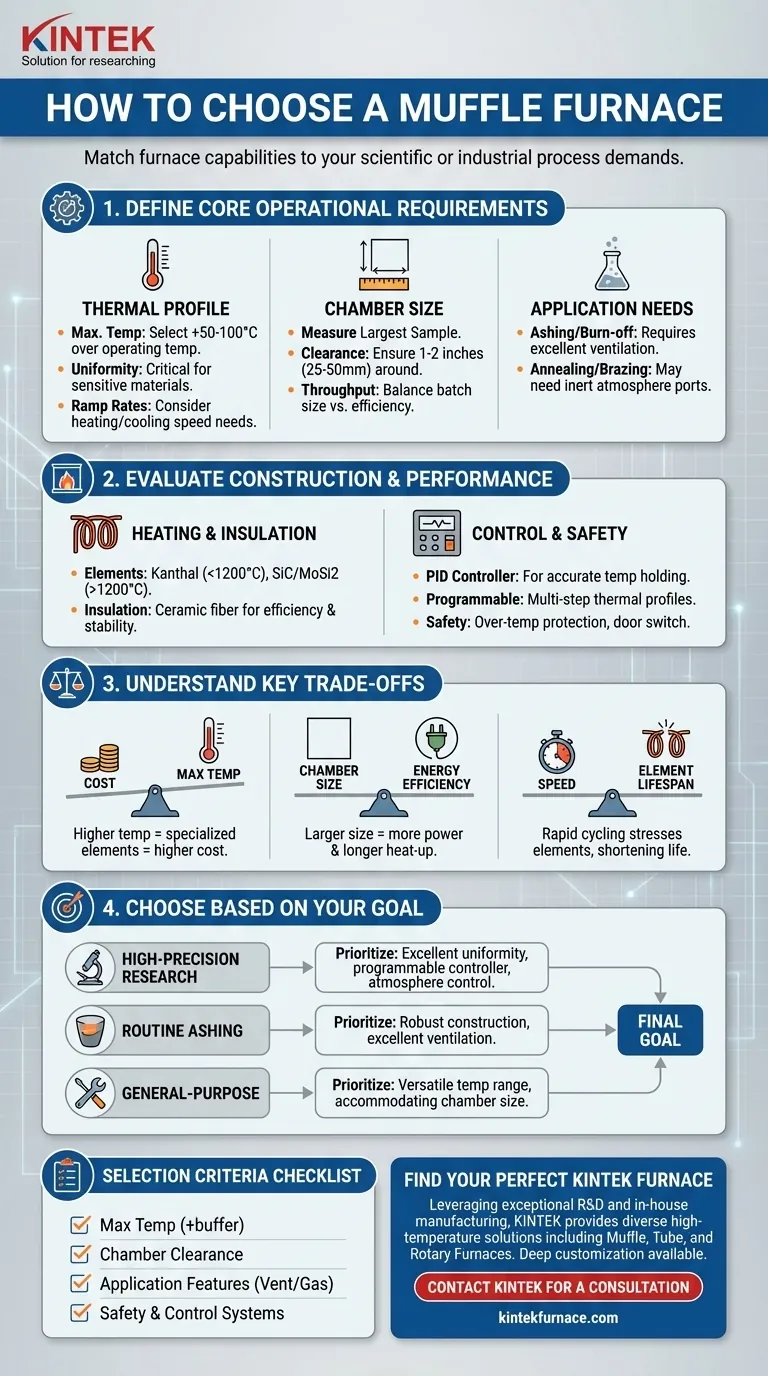

To choose the right muffle furnace, you must first define your core operational requirements. The most critical factors are the maximum temperature you need to achieve, the internal chamber size required for your samples, and the specific application you will be performing, as this dictates needs like ventilation or atmospheric control.

A muffle furnace is not a one-size-fits-all device. The selection process is an exercise in precisely matching the furnace's capabilities—its thermal performance, physical size, and control systems—to the non-negotiable demands of your scientific or industrial process.

Deconstructing Your Core Requirements

Before evaluating any specific model, you must have a clear specification document for your own process. This internal clarity is the most important step.

Defining Your Thermal Profile

The single most important factor is temperature. A furnace that cannot reliably reach and hold your target temperature is useless.

Consider your maximum operating temperature. Always select a furnace with a maximum rating at least 50-100°C higher than your typical working temperature to avoid over-straining the components and ensure longevity.

You must also consider temperature uniformity. This is the variation in temperature across different points within the chamber. For sensitive materials research, a high degree of uniformity is critical, whereas for simple ashing, it may be less of a concern.

Finally, evaluate the required heating and cooling rates. Some processes require rapid thermal cycling, which places significant stress on heating elements and insulation.

Matching Chamber Size to Your Workflow

The furnace's internal volume must accommodate your work. Start by measuring your largest sample or the crucible you intend to use.

Ensure there is adequate clearance—at least 1-2 inches (25-50mm)—around the sample to allow for proper air circulation and uniform heating. Overpacking a furnace is a primary cause of inaccurate results.

Consider your batch size and throughput. A larger chamber allows for processing more samples at once but will consume more energy and take longer to heat up.

Aligning with Your Specific Application

The process itself dictates specialized features. For ashing or burn-off applications, excellent ventilation is mandatory to safely exhaust fumes and smoke. Look for models with a tall exhaust stack.

For processes like annealing or brazing certain metals, you may need an inert atmosphere to prevent oxidation. This requires a furnace with sealed gas ports for introducing nitrogen or argon.

Evaluating Furnace Construction and Performance

Once you know your requirements, you can assess how different furnaces are built to meet them.

Heating Elements and Insulation: The Engine of the Furnace

Heating elements are the heart of the furnace. Most furnaces operating up to 1100-1200°C use Kanthal (FeCrAl) wire elements, which are durable and cost-effective.

For higher temperatures (up to 1700-1800°C), furnaces use Silicon Carbide (SiC) or Molybdenum Disilicide (MoSi2) elements. These are more expensive and can be more brittle but are necessary for high-temperature ceramics and materials science.

High-quality ceramic fiber insulation is key to energy efficiency and temperature stability. Better insulation means less heat escapes, reducing power consumption and keeping the exterior of the furnace cooler and safer.

Temperature Control and Accuracy

Modern furnaces use a PID (Proportional-Integral-Derivative) controller to manage temperature. This system constantly adjusts power to hold the setpoint with high accuracy, preventing over- and undershooting.

For complex processes, look for a programmable controller that allows you to create multi-step thermal profiles (e.g., ramp to 600°C, hold for 2 hours, ramp to 900°C).

Safety Features

Essential safety features are non-negotiable. Look for over-temperature protection, which automatically shuts the furnace down if it exceeds a maximum safe temperature.

A door safety switch that cuts power to the heating elements when the door is opened is another critical feature that protects both the operator and the elements from thermal shock.

Understanding the Trade-offs

Choosing a furnace involves balancing competing priorities. Being aware of these trade-offs will help you make a more informed decision.

Cost vs. Maximum Temperature

There is a direct and steep correlation between price and maximum temperature. The need for specialized heating elements (SiC, MoSi2) and advanced insulation in high-temperature models significantly increases their cost. Do not pay for a temperature range you will never use.

Chamber Size vs. Energy Efficiency

A large, empty furnace is an inefficient one. It consumes more power and takes longer to reach its setpoint. While it's tempting to buy a larger size for future flexibility, a correctly sized furnace for your current workflow will have lower operational costs.

Speed vs. Element Lifespan

Aggressive heating and cooling rates put immense stress on heating elements, shortening their lifespan. If your process does not strictly require rapid cycling, using more moderate ramp rates will significantly extend the life of these critical, consumable components.

Making the Right Choice for Your Goal

Your final decision should be guided by your primary objective.

- If your primary focus is high-precision materials research: Prioritize a furnace with documented excellent temperature uniformity, a multi-step programmable controller, and options for atmosphere control.

- If your primary focus is routine ashing or gravimetric analysis: Prioritize robust construction, excellent ventilation to handle corrosive byproducts, and repeatable performance over cutting-edge features.

- If your primary focus is general-purpose lab or workshop heat treating: Prioritize a versatile temperature range (e.g., up to 1100°C) and a chamber size that accommodates the variety of parts you anticipate working with.

By rigorously defining your process requirements first, you transform a complex purchase into a confident investment in your results.

Summary Table:

| Selection Criteria | Key Considerations |

|---|---|

| Maximum Temperature | Choose a furnace rated 50-100°C higher than your working temperature. |

| Chamber Size | Ensure 1-2 inches of clearance around your largest sample for uniform heating. |

| Application Needs | Ashing requires ventilation; annealing may need an inert atmosphere. |

| Heating Elements | Kanthal (up to 1200°C); SiC/MoSi2 for higher temperatures (up to 1800°C). |

| Key Features | PID controller, programmable profiles, over-temperature protection, door safety switch. |

Ready to Find Your Perfect Muffle Furnace?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, and Rotary Furnaces, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements—whether you need precise temperature uniformity for materials research, robust ventilation for ashing, or versatile heat treating for your workshop.

Let our experts help you make a confident investment in your results.

Contact KINTEL today for a personalized consultation

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity