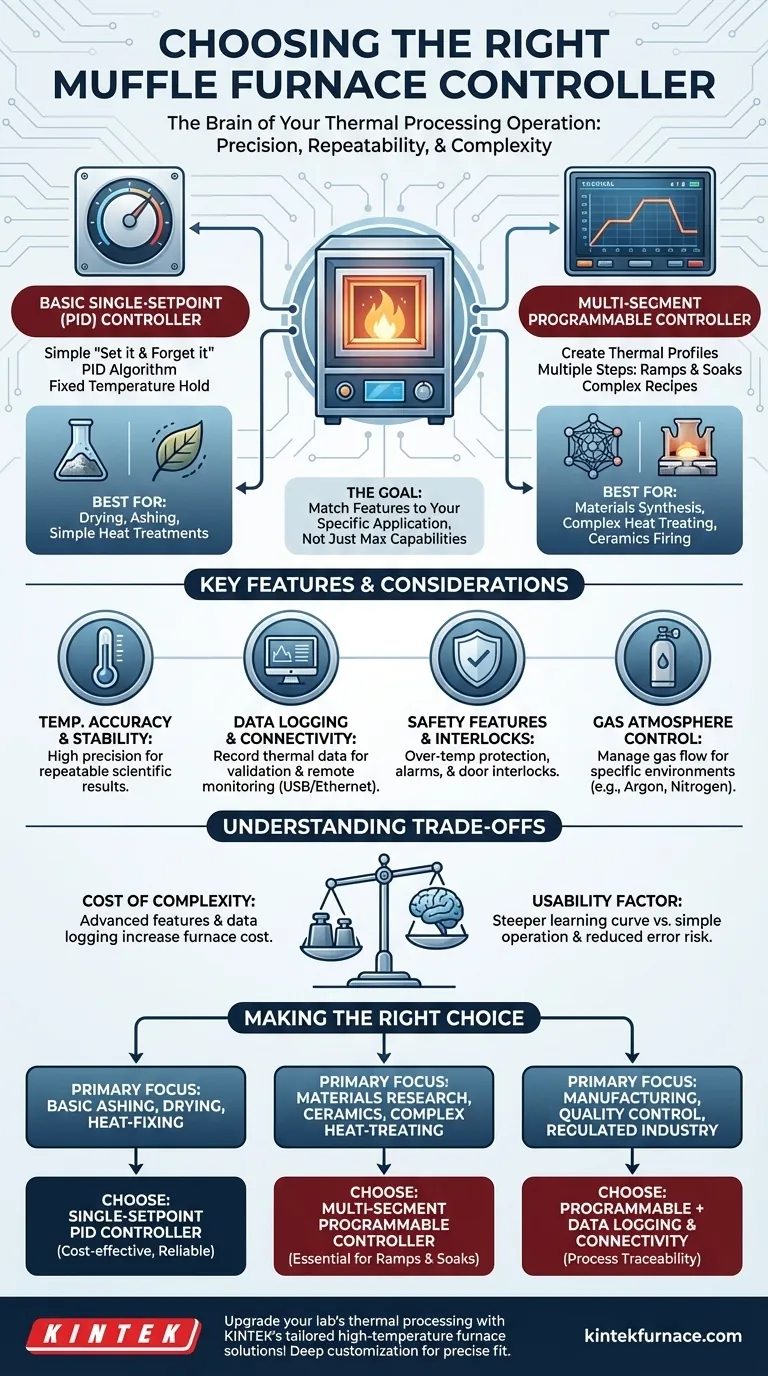

At its core, the furnace controller is the brain of your thermal processing operation. When purchasing a muffle furnace, the controller determines the precision, repeatability, and complexity of the heating cycles you can perform. The primary consideration is choosing between a basic single-setpoint controller for simple tasks or a multi-segment programmable controller for more complex thermal profiles.

The most common mistake is either overpaying for complex programming you will never use or buying a basic controller that limits the future capabilities of your lab. The right choice is not about the most features, but the best fit for your specific application.

The Foundation: Understanding Controller Types

The controller dictates what you can ask the furnace to do. The functionality ranges from a simple "set it and forget it" command to executing a complex, multi-stage recipe over many hours.

Single Setpoint (PID) Controllers

A single setpoint controller is the most basic type. It uses a Proportional-Integral-Derivative (PID) algorithm to bring the furnace to a single target temperature and hold it there.

Think of it like a simple kitchen oven. You set one temperature, and the controller works to maintain it as accurately as possible. These are ideal for straightforward applications like drying, ashing, or simple heat treatments at a static temperature.

Multi-Segment Programmable Controllers

A programmable controller allows you to create a thermal profile with multiple steps. You can define a sequence of temperature changes (ramps) and holds (soaks).

For example, you could program it to:

- Ramp up to 300°C over 30 minutes.

- Soak at 300°C for 2 hours.

- Ramp up to 900°C over 1 hour.

- Soak at 900°C for 5 hours.

- Cool down naturally.

This capability, sometimes called thermal gradient programming, is essential for advanced materials synthesis, complex heat treating, ceramics firing, and other processes that require precise control over the entire heating and cooling cycle. Some advanced industrial systems use Programmable Logic Controllers (PLCs) for even greater robustness and integration.

Key Controller Features and Their Purpose

Beyond the basic type, several specific features determine the controller's true capability and its suitability for your work.

Temperature Accuracy and Stability

This is the controller's ability to first reach the target temperature (accuracy) and then maintain it with minimal fluctuation (stability). For scientific research and quality control, high precision is non-negotiable as it ensures your results are repeatable.

Data Logging and Connectivity

Modern controllers may offer the ability to log temperature data over time. This feature is critical for process validation, quality assurance, and troubleshooting. Connectivity options like USB or Ethernet allow you to export this data for analysis or monitor the furnace remotely.

Safety Features and Interlocks

The controller is central to the furnace's safety. It monitors for over-temperature conditions and can trigger alarms or shut down the heating elements to prevent damage to the furnace and your samples. It can also manage interlocks, such as preventing the door from being opened at high temperatures.

Gas Atmosphere Control

If your process requires a specific atmosphere (e.g., inert gas like Argon or Nitrogen), you will need a controller with outputs that can manage gas flow solenoids. This allows you to program gas injection at specific points in your thermal cycle.

Understanding the Trade-offs

Choosing a controller involves balancing capability, cost, and usability. There is no single "best" option for everyone.

The Cost of Complexity

A multi-segment programmable controller with data logging will significantly increase the cost of the furnace compared to a model with a basic PID controller. It is crucial to assess if you truly need these advanced features for your planned applications.

The Usability Factor

More features can mean a steeper learning curve. A controller with a poorly designed user interface can lead to programming errors, ruining samples and wasting time. Sometimes, the simplicity of a basic controller is a benefit, reducing the chance of operator error.

Reliability and Maintenance

As a general rule, simpler electronic systems have fewer points of failure. While modern programmable controllers are highly reliable, a basic single-setpoint unit is fundamentally a less complex device and may offer easier servicing over the furnace's lifespan.

Making the Right Choice for Your Application

To select the right controller, you must align its capabilities with your primary operational goals.

- If your primary focus is basic ashing, drying, or simple heat-fixing: A standard single-setpoint PID controller is cost-effective, reliable, and perfectly sufficient.

- If your primary focus is materials research, ceramics, or complex heat-treating: A multi-segment programmable controller is essential to precisely manage ramps and soaks.

- If your primary focus is manufacturing or quality control in a regulated industry: Prioritize a programmable controller with robust data logging, alarms, and connectivity for process traceability.

Choosing the right controller ensures your furnace is not just a heat source, but a precise and reliable instrument for your work.

Summary Table:

| Controller Type | Key Features | Best For |

|---|---|---|

| Single Setpoint (PID) | Basic temperature hold, PID algorithm | Simple tasks like drying, ashing, basic heat treatments |

| Multi-Segment Programmable | Thermal profiles, ramps, soaks, data logging | Complex processes like materials synthesis, ceramics firing |

| PLC-Based | High robustness, integration capabilities | Industrial applications with stringent reliability needs |

Upgrade your lab's thermal processing with KINTEK's tailored high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer advanced controllers for Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization ensures precise fit for your unique experimental needs—enhance precision, repeatability, and efficiency. Contact us today to discuss how we can support your specific applications!

Visual Guide

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What role does a laboratory muffle furnace play in high-purity alpha-alumina prep? Master Calcination and Phase Shifts

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What functions does a high-temperature muffle furnace perform during cathode precursor processing?

- What is the function of a high-temperature Muffle Furnace in the two-step heat treatment of PTFE-coated Nickel Foam?