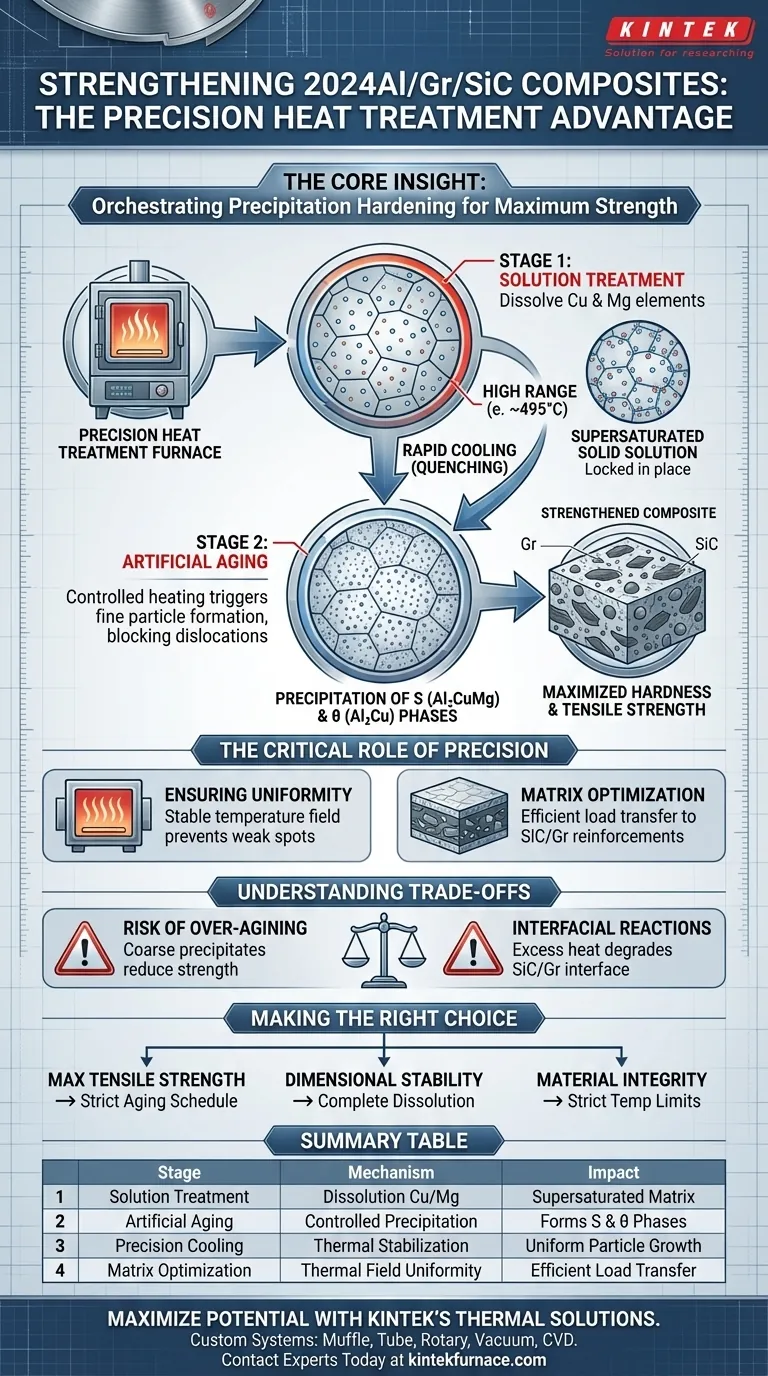

A precision heat treatment furnace strengthens 2024Al/Gr/SiC composites by orchestrating the metallurgical process of precipitation hardening. Specifically, it enables a two-step thermal cycle—solution treatment followed by artificial aging—that modifies the aluminum matrix at the microscopic level.

The Core Insight The furnace does not merely heat the material; it precisely controls the thermal environment to dissolve alloying elements and subsequently precipitate fine strengthening particles. This optimizes the composite's mechanical properties, specifically maximizing hardness and tensile strength through the formation of the S and theta phases.

The Mechanism: Precipitation Hardening

Solution Treatment

The first critical step performed in the furnace is solution treatment. The composite is heated to a specific temperature range to allow alloying elements (primarily Copper and Magnesium in 2024 aluminum) to fully dissolve into the aluminum matrix.

Creating a Supersaturated Solution

Once the elements are dissolved, the material is cooled. This locks the alloying elements in an unstable "supersaturated" solid solution, creating the necessary foundation for strengthening.

Artificial Aging

The furnace then facilitates artificial aging, where the material is held at an elevated but lower temperature. This controlled reheating triggers the precipitation of dissolved elements into fine, dispersed particles throughout the matrix.

Formation of Strengthening Phases

According to the primary reference, this process specifically promotes the precipitation of the S phase (Al2CuMg) and theta phase (Al2Cu). These microscopic precipitates act as obstacles to dislocation movement within the metal, directly increasing the material's hardness and tensile strength.

The Critical Role of Precision

Ensuring Uniformity

A precision furnace provides a stable and uniform temperature field. This uniformity is vital to ensure that the strengthening phases precipitate evenly throughout the entire composite part, preventing weak spots or brittle zones.

Matrix Optimization

By precisely controlling the heating temperature and holding time, the furnace optimizes the aluminum matrix itself. This enhancement of the matrix is essential to support the rigid reinforcements (Graphite and SiC), ensuring the load is effectively transferred between the softer alloy and the hard ceramic particles.

Understanding the Trade-offs

The Risk of Over-Aging

While heat treatment significantly boosts strength, precision is required to avoid "over-aging." If the furnace temperature is too high or the holding time too long, the precipitates can coarsen (grow too large), which actually reduces the material's strength and hardness.

Interfacial Reactions

In composites containing Silicon Carbide (SiC) and Graphite (Gr), excessive temperatures can trigger harmful chemical reactions at the interface between the aluminum and the reinforcements. Precise temperature control limits these reactions, preventing the degradation of the material's structural integrity.

Making the Right Choice for Your Goal

To maximize the performance of 2024Al/Gr/SiC composites, align your heat treatment strategy with your specific mechanical requirements:

- If your primary focus is Maximum Tensile Strength: Prioritize a strict artificial aging schedule to maximize the density of fine S phase and theta phase precipitates.

- If your primary focus is Dimensional Stability: Ensure the solution treatment phase achieves complete dissolution of alloying elements to prevent uneven stress relief later.

- If your primary focus is Material Integrity: utilize strict upper-temperature limits to prevent interfacial reactions between the aluminum matrix and the graphite/SiC reinforcements.

Precision in thermal processing is not just a manufacturing step; it is the defining factor in unlocking the theoretical performance of your composite material.

Summary Table:

| Heat Treatment Stage | Process Mechanism | Impact on 2024Al/Gr/SiC Composite |

|---|---|---|

| Solution Treatment | Dissolution of Cu & Mg | Creates a supersaturated solid solution matrix. |

| Artificial Aging | Controlled precipitation | Forms S (Al2CuMg) and theta (Al2Cu) phases for hardening. |

| Precision Cooling | Thermal stabilization | Locks in unstable alloying elements for uniform particle growth. |

| Matrix Optimization | Thermal field uniformity | Ensures efficient load transfer between alloy and SiC/Gr reinforcements. |

Maximize the Potential of Your Advanced Composites

Unlock the full mechanical strength of your 2024Al/Gr/SiC materials with KINTEK’s industry-leading thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your specific heat treatment cycles. Whether you are aiming for maximum tensile strength or preventing interfacial reactions, our lab high-temp furnaces provide the uniform temperature control essential for complex precipitation hardening.

Ready to elevate your material science? Contact our technical experts today to find the perfect furnace for your unique needs!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the modern applications of Muffle Furnaces? Essential for Clean Heat in Labs and Manufacturing

- What is the function of a muffle furnace in material testing? Achieve Precise Thermal Analysis Without Contamination

- How does a high-precision furnace enhance EIS testing for niobium-doped titanium dioxide? Achieve Accurate Material Data

- What are the limitations of crucible furnaces? Understand Key Trade-offs for Your Lab

- What technological advantages do modern muffle furnaces offer? Achieve Precision and Purity in Thermal Processing

- How should the furnace door be handled during operation? Ensure Safety and Extend Equipment Life

- What are the construction features and temperature capabilities of a muffle furnace? Key Insights for Your Lab

- What role does a muffle furnace play in pharmaceutical applications? Ensuring Drug Purity and Compliance