In modern technical fields, a muffle furnace is the essential tool for any process requiring extremely high, uniform, and contaminant-free heat. Its applications range from foundational laboratory analysis, like determining the ash content of a sample, to advanced manufacturing processes such as creating technical ceramics, heat-treating metals, and sintering 3D-printed parts.

A muffle furnace's primary value is not just its high temperature, but its ability to isolate a material from direct flame and combustion byproducts. This "muffle" design ensures that heat is transferred cleanly, preserving the chemical purity and structural integrity of the sample.

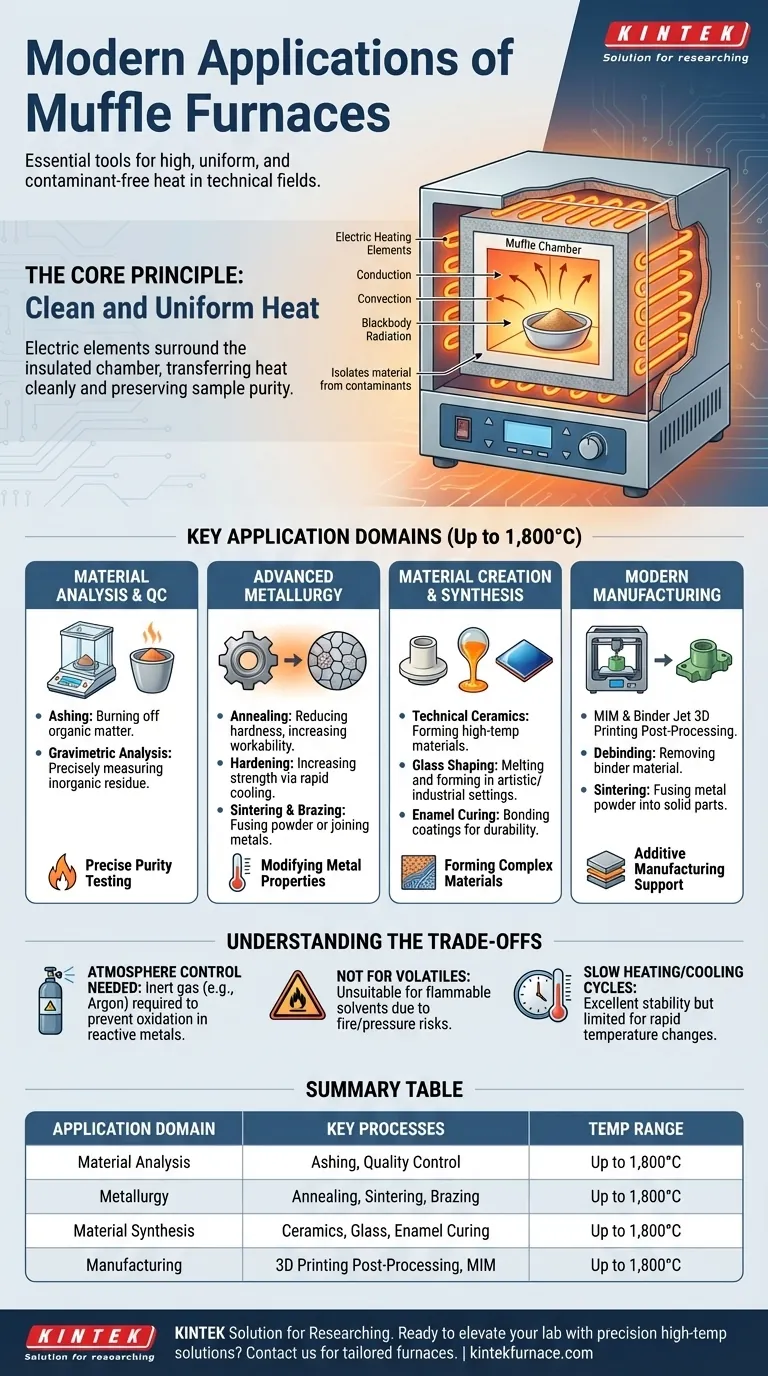

The Core Principle: Clean and Uniform Heat

The defining feature of a muffle furnace is the "muffle" itself—an insulated chamber that separates the material being heated from the actual heating elements or flame.

From Combustion to Conduction

Early furnaces burned fuel, introducing combustion byproducts like soot and gases that could contaminate the workpiece. This made them unsuitable for sensitive applications.

Modern electric muffle furnaces solve this problem entirely. They use high-resistance electric heating elements that surround the outside of the chamber, transferring energy to the sample cleanly through a combination of conduction, convection, and blackbody radiation.

Why Isolation Matters

This isolation is critical for processes where material purity is non-negotiable. It guarantees that any changes to the sample are a result of the heat alone, not a chemical reaction with outside contaminants. This is the foundation of its use in both analytical chemistry and advanced materials science.

Key Application Domains

Muffle furnaces are versatile tools found across research, development, and industrial production. Their applications can be grouped into several key domains, with some capable of reaching temperatures up to 1,800°C (3,272°F).

Material Analysis and Quality Control

This is one of the most common laboratory uses. The furnace provides a stable, controlled environment for testing material properties.

Key processes include ashing, where a sample is burned at a high temperature to burn off all organic matter. This allows researchers to precisely measure the weight of the non-combustible (inorganic) residue, a critical step in many analytical procedures in the pharmaceutical, chemical, and environmental industries.

Advanced Metallurgy and Heat Treatment

In metallurgy, heat is used to alter the physical and chemical properties of metals. A muffle furnace provides the precision required for these transformations.

- Annealing: Heating and slowly cooling a metal (like steel) or glass to reduce hardness and internal stresses, making it more workable.

- Hardening: Heating a metal to a critical temperature and then rapidly cooling it to increase its hardness and strength.

- Sintering: Heating powdered materials (metal or ceramic) to just below their melting point, causing the particles to fuse together into a solid piece.

- Brazing: Joining two pieces of metal using a filler metal that is melted into the joint.

Material Creation and Synthesis

Muffle furnaces are central to the production of materials that require high temperatures to form.

This includes creating technical ceramics, melting and shaping glass in artistic or industrial settings, and curing enamel coatings onto metal substrates for durability and appearance.

Modern Manufacturing and Prototyping

The rise of additive manufacturing has created new applications for muffle furnaces.

In processes like Metal Injection Molding (MIM) and binder jet 3D printing, a "green" part is formed from metal powder held together by a polymer binder. The furnace is used for a two-step post-process:

- Debinding: The part is gently heated to burn away the binder material.

- Sintering: The temperature is increased significantly to fuse the remaining metal powder into a dense, solid metal component.

Understanding the Trade-offs

While powerful, a muffle furnace is a specialized tool with specific operating considerations.

The Need for Atmosphere Control

A standard muffle furnace heats in the presence of air, which will cause many metals to oxidize at high temperatures. For sensitive metallurgical work like bright annealing or sintering reactive metals, the furnace must have the capability to be purged with an inert gas (like argon or nitrogen) to create a controlled, oxygen-free atmosphere.

Not for All Heating Tasks

These furnaces are designed for thermally stable materials. They are generally not suitable for processing samples containing large amounts of volatile or flammable solvents, which could create a fire or pressure hazard within the sealed chamber.

Heating and Cooling Rates

Due to their significant insulation and thermal mass, muffle furnaces provide excellent temperature stability. However, this also means their heating and cooling cycles can be slow. This is a limitation for high-throughput applications that require rapid temperature changes.

Making the Right Choice for Your Goal

Selecting the right thermal processing method depends entirely on your material and desired outcome.

- If your primary focus is analytical testing: A muffle furnace is the standard for its precision in ashing, gravimetric analysis, and determining inorganic content.

- If your primary focus is modifying metal properties: You need a muffle furnace with atmosphere control for processes like annealing and sintering without oxidation.

- If your primary focus is creating new materials or parts: A high-temperature muffle furnace is essential for sintering ceramics, forming glass, and post-processing 3D-printed components.

Ultimately, a muffle furnace is the definitive tool when your process demands absolute thermal precision and material purity.

Summary Table:

| Application Domain | Key Processes | Temperature Range |

|---|---|---|

| Material Analysis | Ashing, Quality Control | Up to 1,800°C |

| Metallurgy | Annealing, Sintering, Brazing | Up to 1,800°C |

| Material Synthesis | Ceramics, Glass, Enamel Curing | Up to 1,800°C |

| Manufacturing | 3D Printing Post-Processing, MIM | Up to 1,800°C |

Ready to elevate your lab's capabilities with precision high-temperature solutions? KINTEK specializes in advanced muffle, tube, rotary, vacuum, atmosphere furnaces, and CVD/PECVD systems, backed by exceptional R&D and in-house manufacturing. Our deep customization ensures your unique experimental needs in material analysis, metallurgy, and 3D printing are met with contaminant-free, uniform heating up to 1,800°C. Contact us today to discuss how our tailored furnace solutions can drive your research and production forward!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity