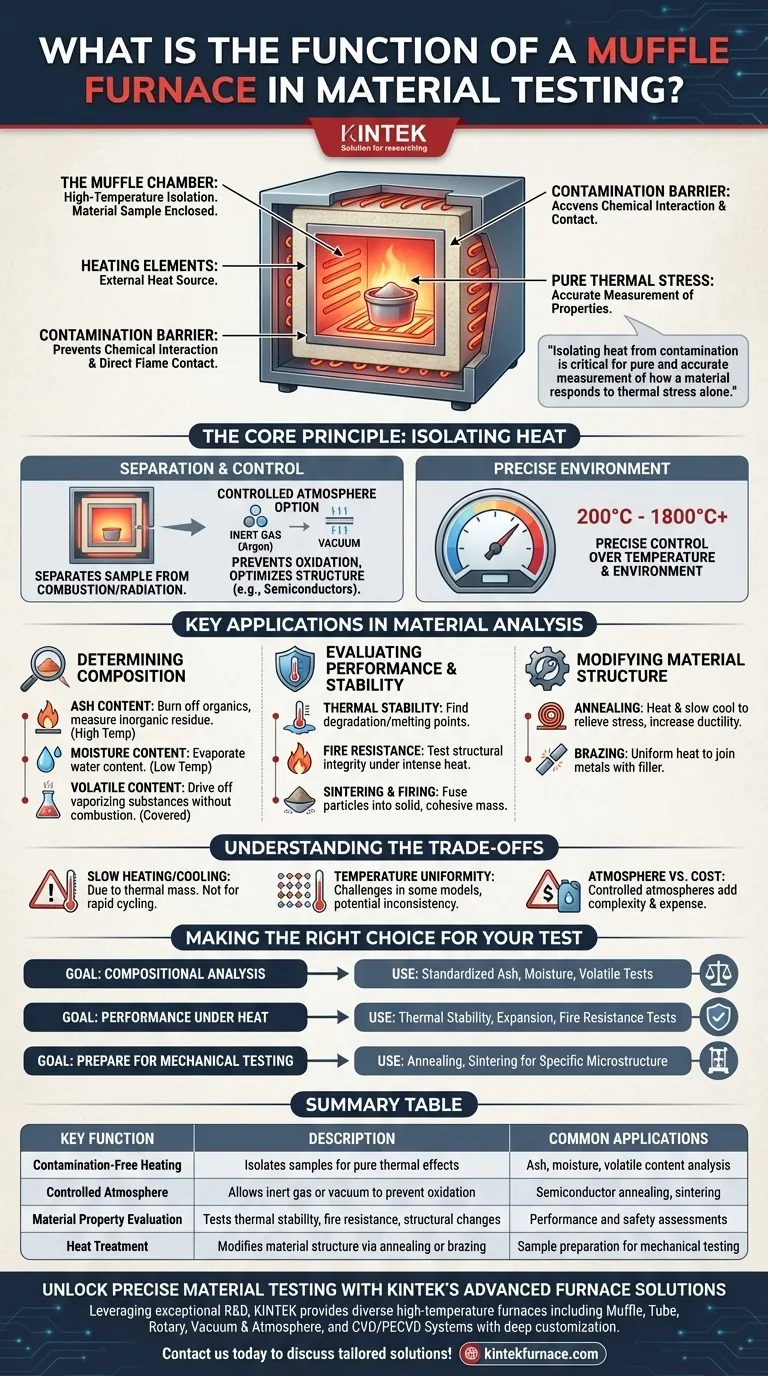

In material testing, a muffle furnace is a high-temperature oven used to heat a material in a controlled environment without direct contact with flames or heating elements. This isolation allows engineers and scientists to precisely analyze a material's properties and behavior under the sole influence of extreme thermal energy, revealing its strength, stability, and composition.

The core function of a muffle furnace is not simply to heat a material, but to do so in a way that prevents chemical contamination. This allows for the pure and accurate measurement of how a material responds to thermal stress alone, which is critical for predicting its performance in real-world applications.

The Core Principle: Isolating Heat from Contamination

A muffle furnace's design is fundamental to its purpose. The name itself provides the key insight into its operation.

What "Muffle" Means

The term "muffle" refers to the inner chamber that encloses the material sample. This chamber is heated from the outside by electric heating elements.

This design is critical because it separates the sample from the combustion byproducts or direct radiation of the heating source. This prevents unwanted chemical reactions or contamination, ensuring that any changes observed in the material are a direct result of the applied temperature.

Creating a Controlled Atmosphere

This separation allows for precise control over the environment surrounding the sample. Advanced furnaces can operate with specific atmospheres, such as inert gases (like argon) to prevent oxidation or even a vacuum.

This capability is essential in fields like semiconductor manufacturing, where annealing silicon wafers in a controlled atmosphere is necessary to optimize their crystal structure and electrical conductivity.

Key Applications in Material Analysis

Muffle furnaces are versatile tools used for a wide range of destructive and non-destructive tests. These applications fall into two main categories: determining a material's inherent properties and modifying its structure for further testing.

Determining Material Composition

Some of the most fundamental material tests involve breaking a substance down to understand its makeup.

- Ash Content: The furnace is used to completely burn off all organic matter in a sample at a high temperature, leaving only the inorganic, non-combustible ash behind. The remaining weight reveals the ash percentage.

- Moisture Content: By heating a sample at a relatively low but precise temperature (e.g., just over 100°C), the furnace removes all water content through evaporation. The weight difference before and after heating determines the moisture content.

- Volatile Content: This test measures substances that vaporize at high temperatures. The furnace heats a sample in a covered crucible to drive off volatile matter without combusting it.

Evaluating Performance and Stability

These tests measure how a material behaves under thermal stress, which is vital for safety and reliability engineering.

- Thermal Stability: Samples are heated to determine the temperature at which they begin to degrade, melt, or otherwise change structurally.

- Fire Resistance: Materials intended for use in high-temperature environments are tested to see how long they can maintain their structural integrity when exposed to intense heat.

- Sintering and Firing: In ceramics and powder metallurgy, the furnace is used to fuse particles into a solid, cohesive mass. This process itself is a test of the material's ability to form a high-performance final product.

Modifying Material Structure (Heat Treatment)

Sometimes, the goal is not to measure a property but to change it intentionally before performing other tests.

- Annealing: Metals are heated and then slowly cooled to relieve internal stresses, increase their ductility, and soften them. The annealed material can then be subjected to mechanical tests, like tensile strength analysis.

- Brazing: The furnace provides uniform, controlled heat for joining metal parts using a filler metal, a common manufacturing and prototyping technique.

Understanding the Trade-offs

While incredibly useful, a muffle furnace is not the right tool for every thermal application. Understanding its limitations is key to generating accurate results.

Slow Heating and Cooling Rates

Due to their significant thermal mass and heavy insulation, muffle furnaces heat up and cool down slowly. This makes them unsuitable for applications requiring rapid thermal cycling or quenching.

Temperature Uniformity

Achieving perfect temperature uniformity throughout the entire chamber can be a challenge in some models. Samples placed in different locations may experience slightly different temperatures, potentially affecting the consistency of results for sensitive materials.

Atmosphere vs. Cost

Basic muffle furnaces operate with ambient air. Models that allow for controlled atmospheres (vacuum or inert gas) are significantly more complex and expensive. The choice depends entirely on whether preventing oxidation is critical for the test.

Making the Right Choice for Your Test

To use a muffle furnace effectively, you must first define your analytical goal. The same tool can be used for vastly different purposes depending on the procedure.

- If your primary focus is compositional analysis: Use the furnace for standardized ash, moisture, or volatile content tests to understand your material's basic makeup.

- If your primary focus is performance under heat: Use the furnace to directly test for thermal stability, expansion, and fire resistance to evaluate real-world durability.

- If your primary focus is preparing a sample for mechanical testing: Use processes like annealing or sintering to create a material with a specific microstructure before conducting tensile or hardness tests.

Ultimately, the muffle furnace empowers you to isolate and understand the fundamental impact of temperature on a material's composition, integrity, and performance.

Summary Table:

| Key Function | Description | Common Applications |

|---|---|---|

| Contamination-Free Heating | Isolates samples from flames/elements for pure thermal effects | Ash, moisture, volatile content analysis |

| Controlled Atmosphere | Allows inert gas or vacuum to prevent oxidation | Semiconductor annealing, sintering |

| Material Property Evaluation | Tests thermal stability, fire resistance, and structural changes | Performance and safety assessments |

| Heat Treatment | Modifies material structure via annealing or brazing | Sample preparation for mechanical testing |

Unlock Precise Material Testing with KINTEK's Advanced Furnace Solutions

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're analyzing material composition, evaluating thermal performance, or preparing samples for further testing, our furnaces ensure contamination-free, controlled heating for accurate results.

Contact us today to discuss how our tailored solutions can enhance your material testing processes and drive innovation in your lab!

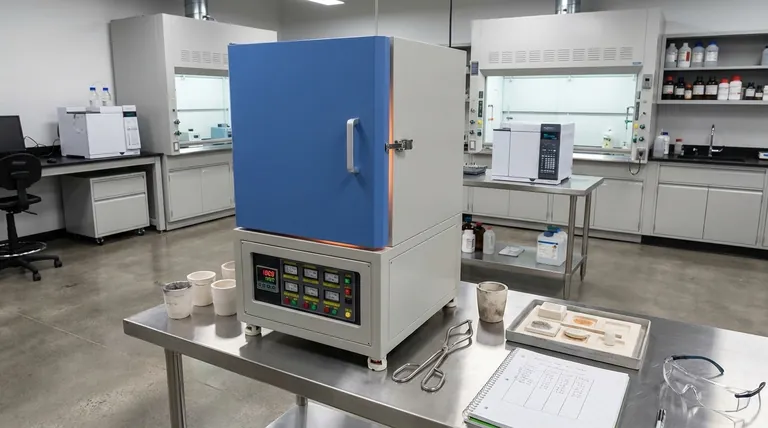

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis