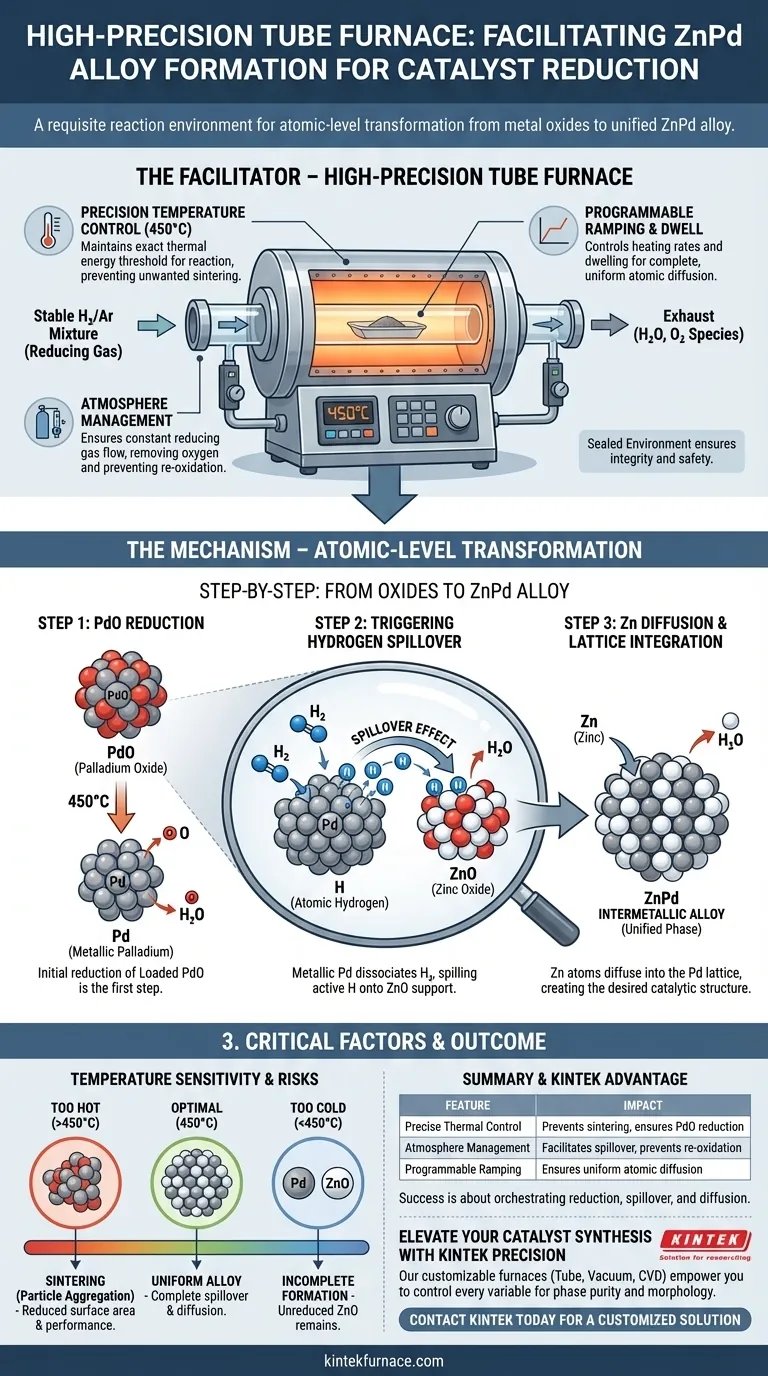

A high-precision tube furnace serves as the requisite reaction environment that enables the atomic-level transformation of metal oxides into a unified ZnPd alloy. By maintaining a stable hydrogen flow and rigorous temperature control—specifically at 450°C—it triggers the reduction of palladium oxide, initiating a cascade of atomic diffusion events essential for alloy formation.

The furnace’s distinct value lies in its ability to sustain a precise thermal and reductive atmosphere that drives the hydrogen spillover effect. This phenomenon allows reduced palladium to catalyze the reduction of adjacent zinc oxide, enabling zinc atoms to diffuse into the palladium lattice and lock into a stable ZnPd intermetallic phase.

The Mechanics of Phase Transformation

Precision Temperature Control

The formation of the ZnPd alloy requires a specific thermal energy threshold, typically centered around 450°C.

The tube furnace maintains this exact temperature to ensure the environment is energetic enough to induce chemical changes but stable enough to prevent unwanted sintering.

This thermal consistency is vital for the initial reduction of loaded palladium oxide (PdO), which is the first step in the reaction sequence.

Triggering the Hydrogen Spillover Effect

Once the palladium oxide is reduced to metallic palladium, the furnace's stable hydrogen flow facilitates the hydrogen spillover effect.

In this process, the metallic palladium dissociates molecular hydrogen into active atomic hydrogen.

These active hydrogen atoms then migrate ("spill over") from the palladium surface to the adjacent zinc oxide (ZnO) support, triggering its localized reduction.

Atomic Diffusion and Lattice Integration

The reduction of zinc oxide releases zinc atoms in close proximity to the palladium.

Because the furnace maintains a controlled thermal state, these zinc atoms are able to effectively diffuse into the palladium lattice.

This diffusion transforms the separate metallic states into a unified, single-phase ZnPd intermetallic alloy, creating the desired catalytic structure.

The Critical Role of Atmosphere Management

Stable Reductive Environment

Beyond temperature, the tube furnace ensures a constant supply of reducing gas, such as a hydrogen/argon mixture.

This continuous flow removes oxygen species released during the reduction process, preventing re-oxidation.

The furnace's sealed environment ensures that the partial pressure of hydrogen remains constant, which is uniform reduction across the entire catalyst bed.

Controlling Heating Rates and Dwell Times

The quality of the final alloy depends heavily on how the material reaches its target temperature.

A high-precision furnace allows for programmable heating rates, preventing thermal shock that could alter the catalyst's morphology.

Precise management of the dwelling time ensures that the diffusion of zinc into the palladium lattice is complete, avoiding a mix of alloyed and unalloyed phases.

Understanding the Trade-offs

Sensitivity to Temperature Fluctuations

While high temperatures facilitate diffusion, deviation from the optimal 450°C range carries risks.

Excessive heat can lead to particle aggregation or sintering, where the nanoparticles clump together, reducing the active surface area and catalytic performance.

Conversely, insufficient heat will fail to trigger the full hydrogen spillover effect, leaving unreduced zinc oxide and preventing true alloy formation.

Atmosphere Purity and Safety

The use of hydrogen gas necessitates strict safety protocols and atmosphere purity.

Any leak in the tube furnace or contamination of the gas feed with oxygen can compromise the reduction process or create safety hazards.

The "high-precision" aspect of the equipment refers not just to heat, but to the integrity of the seals and mass flow controllers that maintain the inert/reducing balance.

Making the Right Choice for Your Goal

To maximize the efficacy of your ZnPd catalyst preparation, you must align the furnace capabilities with your specific synthesis objectives.

- If your primary focus is Phase Purity: Prioritize a furnace with multi-zone temperature control to ensure the entire sample remains exactly at 450°C, guaranteeing complete hydrogen spillover and uniform alloying.

- If your primary focus is Particle Morphology: Focus on the precision of the gas flow controllers and heating ramp rates to prevent particle sintering while ensuring effective reduction.

Success in forming ZnPd alloys is not just about applying heat; it is about orchestrating a precise synchronization of reduction, spillover, and diffusion.

Summary Table:

| Feature | Mechanism in ZnPd Formation | Impact on Catalyst Quality |

|---|---|---|

| Precise Thermal Control | Maintains exact 450°C threshold | Prevents sintering; ensures complete PdO reduction |

| Atmosphere Management | Sustains stable hydrogen/argon flow | Facilitates hydrogen spillover and prevents re-oxidation |

| Programmable Ramping | Controls heating rates and dwell times | Ensures uniform atomic diffusion into the Pd lattice |

| Sealed Environment | High-integrity gas flow and seals | Guarantees phase purity and operational safety |

Elevate Your Catalyst Synthesis with KINTEK Precision

Achieving the perfect ZnPd intermetallic phase requires more than just heat—it demands absolute thermal and atmospheric synchronization. KINTEK provides industry-leading Tube, Vacuum, and CVD systems designed specifically for high-stakes R&D and manufacturing.

Our customizable high-temperature furnaces empower researchers to control every variable of the hydrogen spillover effect, from precise 450°C dwelling to automated gas flow management. Partner with KINTEK experts to optimize your reduction stages and ensure phase purity.

Contact KINTEK Today for a Customized Solution

Visual Guide

References

- C. Romero, R.M. Navarro. Methanol Synthesis from CO2 over ZnO-Pd/TiO2 Catalysts: Effect of Pd Precursors on the Formation of ZnPd-ZnO Active Sites. DOI: 10.3390/catal15010055

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What role does a Tube Furnace play in HDS catalyst de-oiling? Unlock Efficient Pyrolysis Recovery

- How can the uniform length of a tube furnace be improved? Boost Temperature Uniformity with Proven Methods

- What is the future potential of fluidized bed vertical tube furnaces? Unlock Efficiency and Growth in Your Industry

- What is the specific role of a tube furnace in the pre-treatment of activated carbon catalysts? Precision Modification

- What role does a vacuum tube furnace play in the preparation of wheat straw biochar? Master Controlled Pyrolysis

- Why is a vacuum-sealed quartz tube necessary for LaMg6Ga6S16 synthesis? Ensure Purity in Sulfide Production

- How do vertical fluidized bed tube furnaces contribute to the new energy field? Unlock Next-Gen Energy Material Development

- Why is a tube furnace with multiple zones required for MoSe2 selenization? Achieve Precision Gradient Control