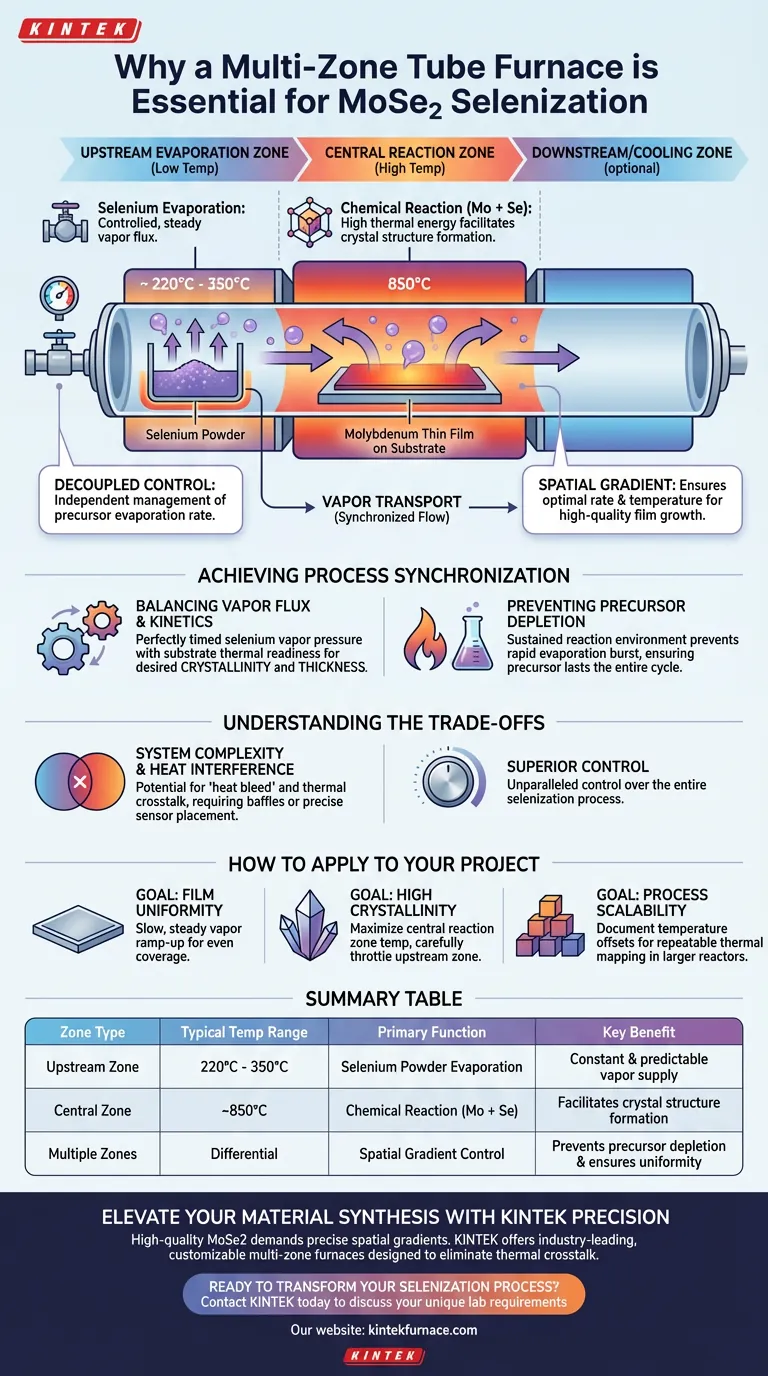

Precision thermal control is the foundational requirement for high-quality MoSe2 synthesis. A tube furnace with multiple independent temperature zones is necessary because it allows for the simultaneous, yet separate, control of selenium evaporation and the subsequent chemical reaction. By establishing a precise spatial temperature gradient, the system ensures that selenium vapor is delivered to the molybdenum substrate at the optimal rate and temperature for high-quality film growth.

The multi-zone configuration is critical because it decouples the precursor evaporation rate from the reaction kinetics. This allows researchers to maintain a steady flux of selenium gas while providing the high thermal energy required for the chemical transformation of the molybdenum thin film.

The Role of Spatial Temperature Gradients

The Upstream Evaporation Zone

The upstream zone is specifically dedicated to heating the selenium powder to its specific evaporation point. Because selenium transitions into a gaseous state at a lower temperature than the reaction requires, this zone must be controlled independently to prevent the precursor from being consumed too quickly. This independent control ensures a constant and predictable supply of selenium vapor throughout the entire process.

The Central Reaction Zone

The central zone is maintained at a significantly higher temperature, typically around 850 °C. This high heat is essential to facilitate the chemical reaction between the gaseous selenium and the solid molybdenum thin film deposited on the substrate. Without this localized high-temperature environment, the selenium gas would likely pass over the substrate without successfully forming the MoSe2 crystal structure.

Achieving Process Synchronization

Balancing Vapor Flux and Reaction Kinetics

A multi-zone furnace allows for the synchronization of two distinct physical states within the same reactor. By adjusting the upstream and central zones separately, the operator can ensure that the selenium vapor pressure is perfectly timed with the substrate's thermal readiness. This synchronization is the primary factor in determining the crystallinity and thickness of the resulting MoSe2 layer.

Preventing Precursor Depletion

In a single-zone system, the entire tube reaches a uniform temperature, which often causes the selenium to evaporate too rapidly. This leads to a "burst" of vapor that is exhausted before the molybdenum film has reached the necessary temperature to react. Independent zones allow for a sustained reaction environment, ensuring the precursor lasts for the duration of the growth cycle.

Understanding the Trade-offs

System Complexity and Heat Interference

While multi-zone furnaces offer superior control, they introduce mechanical and thermal complexity. Heat from the high-temperature central zone can "bleed" into the upstream zone, making it difficult to maintain a perfectly stable evaporation temperature. Operators must often use physical baffles or precise sensor placement to mitigate this thermal crosstalk between the independent stages.

How to Apply This to Your Project

Making the Right Choice for Your Goal

- If your primary focus is film uniformity: Utilize the independent zones to create a slow, steady ramp-up of selenium vapor to ensure even coverage across the entire substrate.

- If your primary focus is high crystallinity: Maximize the temperature of the central reaction zone while carefully throttling the upstream zone to prevent precursor waste.

- If your primary focus is process scalability: Document the specific temperature offsets between zones to create a repeatable thermal "map" for larger reactor volumes.

Mastering the spatial gradient of your furnace transforms selenization from an unpredictable chemical event into a repeatable engineering process.

Summary Table:

| Zone Type | Typical Temp Range | Primary Function | Key Benefit |

|---|---|---|---|

| Upstream Zone | 220°C - 350°C | Selenium Powder Evaporation | Constant & predictable vapor supply |

| Central Zone | ~850°C | Chemical Reaction (Mo + Se) | Facilitates crystal structure formation |

| Multiple Zones | Differential | Spatial Gradient Control | Prevents precursor depletion & ensures uniformity |

Elevate Your Material Synthesis with KINTEK Precision

High-quality MoSe2 synthesis demands more than just heat; it requires the precise spatial temperature gradients only a multi-zone system can provide. KINTEK offers industry-leading, customizable Tube, Muffle, Rotary, and CVD systems backed by expert R&D and manufacturing. Our multi-zone tube furnaces are designed to eliminate thermal crosstalk and provide the synchronization needed for superior crystallinity and film uniformity.

Ready to transform your selenization process? Contact KINTEK today to discuss your unique lab requirements

Visual Guide

References

- Xunjia Zhao, Xiufeng Song. High-sensitivity hybrid MoSe<sub>2</sub>/AgInGaS quantum dot heterojunction photodetector. DOI: 10.1039/d3ra07240a

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What is the primary function of a tube furnace in the pyrolysis of biomass? Achieve Precision in Material Research

- Why is precise atmosphere control necessary in a laboratory tube furnace for Ni-ZIF-8 to Ni-N-C conversion?

- How is tantalum disulfide prepared using a tube furnace? Master the Two-Step Synthesis for High-Quality Crystals

- What is the primary purpose of using a Quartz Tube Furnace for MoS2 annealing? Unlock High Electrical Performance

- Why is a tube furnace with precise temperature control required for CuSbSe2 thin films? Achieve High Phase Purity

- What role does a high-temperature tube furnace play in the synthesis of SiC nanofibers? Precision CVD Growth at 1100°C

- What role does a high-temperature tube furnace play in POLO contact structures? Unlock High-Efficiency Silicon Contacts

- How do multi zone tube furnaces contribute to materials science research? Unlock Precise Temperature Control for Advanced Synthesis