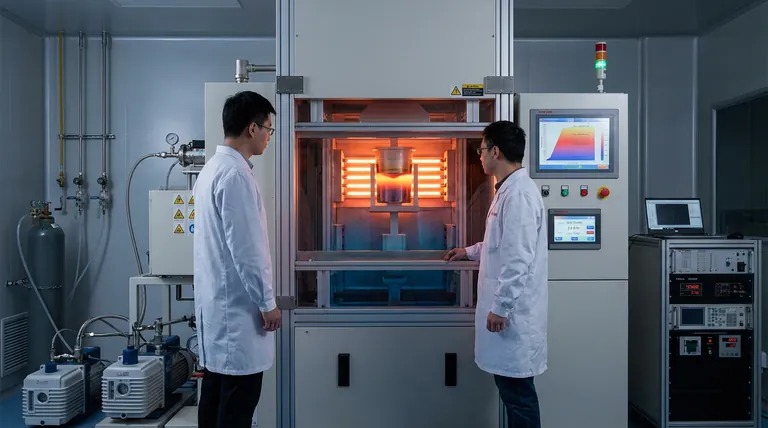

A Bridgman crystal growth furnace ensures the quality of (Bi2Te3)1-c(Sb2Te)c crystals by strictly enforcing a precise temperature gradient and utilizing an extremely slow mechanical translation speed. By maintaining a cooling rate as low as 2.8 K per hour, the system facilitates directional solidification. This controlled environment minimizes structural chaos, resulting in low defect densities and the formation of quasi-single crystal structures essential for high-performance applications.

Success in the Bridgman method relies on the precise synchronization of thermal gradients and slow translation speeds. This rigorous control forces directional solidification, directly reducing material defects to unlock superior electrical transport properties.

The Mechanics of Quality Control

Establishing the Temperature Gradient

The furnace does not simply heat the material; it maintains a sharp, consistent temperature gradient. This gradient creates a distinct boundary between the molten material and the solidifying crystal.

The Role of Slow Translation

The physical movement of the sample through the furnace is deliberately sluggish. The primary reference highlights a cooling rate of 2.8 K per hour.

Enabling Atomic Arrangement

This slow translation is critical for quality. It provides the atoms in the melt sufficient time to align correctly into a lattice structure as they transition to a solid state.

Impact on Material Structure

Achieving Directional Solidification

The combination of the thermal gradient and slow speed induces directional solidification. Instead of freezing randomly, the crystal grows in a single, uniform direction.

Creating Quasi-Single Structures

This process results in a quasi-single crystal structure. Unlike polycrystalline materials, which consist of many fragmented grains, this structure offers better uniformity.

Minimizing Defect Densities

Rapid cooling causes stress, fractures, and atomic misalignment. The controlled Bridgman environment ensures low defect densities, producing a physically robust and chemically consistent material.

Enhancing Electrical Characteristics

The ultimate goal of this structural perfection is functional performance. The lack of defects ensures the material exhibits superior electrical transport characteristics, which is vital for thermoelectric applications.

Understanding the Trade-offs

The Time-Intensive Nature

The primary constraint of this method is throughput. A rate of 2.8 K per hour means the growth process is exceptionally time-consuming compared to other manufacturing methods.

Sensitivity to Fluctuations

Because the process is so slow, the system must remain stable for long periods. Any fluctuation in the temperature gradient or translation speed during the long growth cycle can introduce defects.

Making the Right Choice for Your Goal

To maximize the quality of (Bi2Te3)1-c(Sb2Te)c crystals, you must prioritize process control over production speed.

- If your primary focus is structural integrity: Ensure your mechanical translation is set to an extremely low speed (near 2.8 K/hr) to minimize defect density.

- If your primary focus is electrical performance: Verify that the temperature gradient is perfectly stable to facilitate the quasi-single crystal growth required for optimal transport.

Precision in the growth phase is the only path to superior material performance.

Summary Table:

| Key Quality Factor | Mechanism | Impact on Crystal |

|---|---|---|

| Thermal Gradient | Sharp temperature boundary | Enables controlled directional solidification |

| Cooling Rate | 2.8 K per hour (Ultra-slow) | Provides sufficient time for perfect atomic alignment |

| Mechanical Speed | Sluggish translation | Minimizes stress and reduces defect densities |

| Material Structure | Quasi-single crystal growth | Enhances electrical transport characteristics |

Elevate Your Crystal Growth Precision with KINTEK

To achieve high-performance thermoelectric materials like (Bi2Te3)1-c(Sb2Te)c, you need a thermal environment that offers uncompromising stability. KINTEK provides expert-engineered high-temperature solutions, including specialized Vacuum, Tube, and CVD systems, designed to meet the rigorous demands of directional solidification and single-crystal growth.

Whether you require precise mechanical translation or custom-calibrated thermal gradients, our R&D and manufacturing teams are ready to build a system tailored to your unique research or production needs.

Ready to minimize defect densities and optimize material performance? Contact KINTEK Today to Consult Our Experts

References

- Hung‐Wei Chen, Hsin‐Jay Wu. Dilute Sb Doping Yields Softer <i>p</i>‐Type Bi<sub>2</sub>Te<sub>3</sub> Thermoelectrics. DOI: 10.1002/aelm.202300793

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Magnesium Extraction and Purification Condensing Tube Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What environmental conditions does a vacuum tube furnace provide for sawdust biochar? Achieve Precise Pyrolysis Control

- How can the performance of a vertical tube furnace be optimized? Boost Efficiency and Precision in Heat Treatment

- What is the role of an inert gas protection tube furnace in hardening High Vanadium HSS? Achieve Precision Hardness

- What is a vertical tube furnace and how does it function? Optimize Material Processing with Precision

- What components are in a turn-key quartz tube furnace? Essential parts for precise atmospheric control.

- What is the primary function of a CVD tube furnace in the preparation of Multi-Layer Graphene? Expert Guide

- How is a sample introduced into a graphite furnace? Master Precise Analysis with Expert Techniques

- How does a quartz tube furnace facilitate diamond water vapor annealing? Enhance Interface Stability at 500 °C