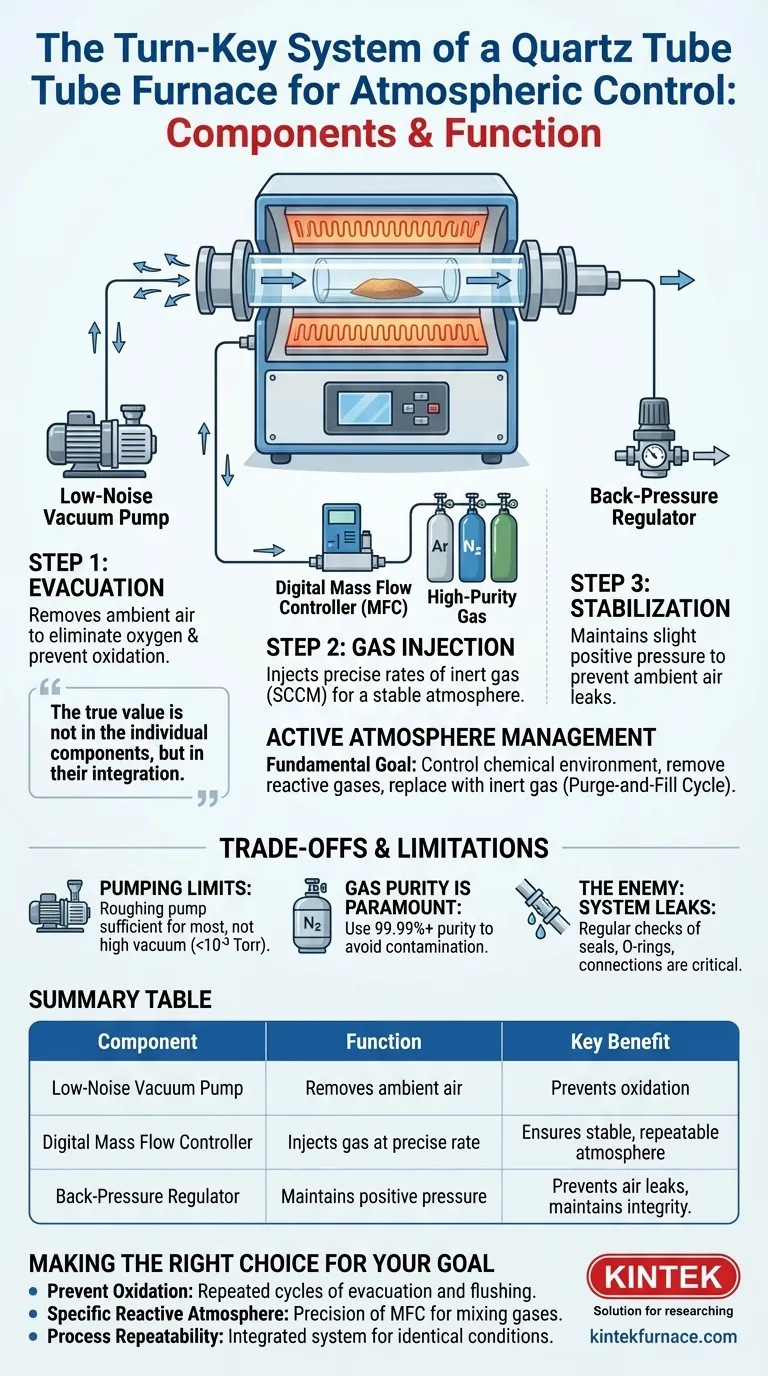

A turn-key quartz tube furnace for atmospheric control includes three primary components: a low-noise vacuum pump, a digital mass flow controller, and a back-pressure regulator. These elements work in concert to first remove the ambient air from the quartz heating chamber and then introduce and maintain a precise, controlled gas environment for thermal processing.

The true value of a turn-key system is not in the individual components, but in their integration. It provides a reliable and repeatable method for creating a specific, non-reactive atmosphere, which is essential for preventing oxidation and ensuring consistent experimental results.

The Core Principle: Active Atmosphere Management

The fundamental goal is to control the chemical environment surrounding your sample during heating. In most cases, this means removing reactive gases like oxygen and water vapor and replacing them with an inert gas like argon or nitrogen.

A turn-key system automates this process of evacuation and replacement, often referred to as a purge-and-fill cycle.

The Vacuum Pump: Creating the Void

The process begins with evacuation. The vacuum pump is responsible for removing the ambient air from the sealed quartz tube chamber.

This initial step is critical because it removes the vast majority of oxygen that would otherwise react with and contaminate your sample at high temperatures. The "low-noise" specification is a practical feature for maintaining a comfortable lab environment.

The Mass Flow Controller (MFC): Precision Gas Injection

Once a vacuum is established, the digital mass flow controller (MFC) takes over. Its job is to inject a specific gas (or a mixture of gases) into the chamber at a precisely controlled rate.

Unlike a simple valve, an MFC measures and controls the volume of gas per unit of time (e.g., standard cubic centimeters per minute or SCCM). This precision is vital for creating a stable, repeatable atmosphere from one experiment to the next.

The Back-Pressure Regulator: Maintaining Stability

The back-pressure regulator works in tandem with the MFC to maintain a slight, constant positive pressure inside the quartz tube.

This positive pressure is a crucial safeguard. It ensures that if any microscopic leaks exist in the system's seals, the controlled gas will flow outward, preventing ambient air from leaking inward and compromising the integrity of your atmosphere.

Understanding the Trade-offs and Limitations

A turn-key system provides immense value, but it's important to understand its operational boundaries.

The Limits of Pumping

The included vacuum pump is typically a roughing pump, designed for efficient chamber evacuation, not for creating a high vacuum. This is perfectly sufficient for preventing oxidation in most material processing applications.

However, for processes requiring true high-vacuum conditions (below 10⁻³ Torr), a more advanced and expensive turbomolecular pumping system would be necessary.

Gas Purity is Paramount

The quality of your controlled atmosphere is only as good as the source gas you supply. Using a low-purity gas tank will introduce contaminants, defeating the purpose of the control system.

Always use high-purity (99.99% or greater) or ultra-high-purity inert gases to achieve the best results.

The Enemy: System Leaks

The most common point of failure in any atmospheric control system is a leak. Even with perfect components, a poorly sealed flange or a cracked tube will allow oxygen to enter the chamber.

Regularly checking all seals, O-rings, and connections for integrity is a critical part of a successful workflow.

Making the Right Choice for Your Goal

The integrated system allows you to reliably tailor the process to your specific experimental needs.

- If your primary focus is preventing oxidation: The key is using repeated cycles of evacuation with the pump and flushing with an inert gas via the MFC.

- If your primary focus is creating a specific reactive atmosphere: The precision of the Mass Flow Controller is the most critical component for mixing gases in exact ratios.

- If your primary focus is process repeatability: The entire integrated system is essential, as it allows you to program and execute identical atmospheric conditions for every run.

By understanding how these components function together, you can effectively control your sample's environment and achieve reliable, high-quality results.

Summary Table:

| Component | Function | Key Benefit |

|---|---|---|

| Low-Noise Vacuum Pump | Removes ambient air from the chamber | Prevents oxidation by eliminating oxygen |

| Digital Mass Flow Controller | Injects gas at a precise rate | Ensures stable, repeatable atmosphere |

| Back-Pressure Regulator | Maintains positive pressure inside the tube | Prevents air leaks and maintains gas integrity |

Unlock precise atmospheric control for your lab with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all supported by deep customization capabilities to meet your unique experimental requirements. Contact us today to enhance your thermal processing efficiency and achieve reliable results!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a vertical tube furnace facilitate the simulation of the industrial sintering process for iron ores?

- What core process conditions does a tube furnace provide? Mastering Catalyst Precursor Treatment

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What are the material requirements for furnace tubes? Optimize Performance and Safety in High-Temperature Labs

- How do roller kilns and tube furnaces differ in their use of Alumina ceramic tubes? Compare Transport vs. Containment