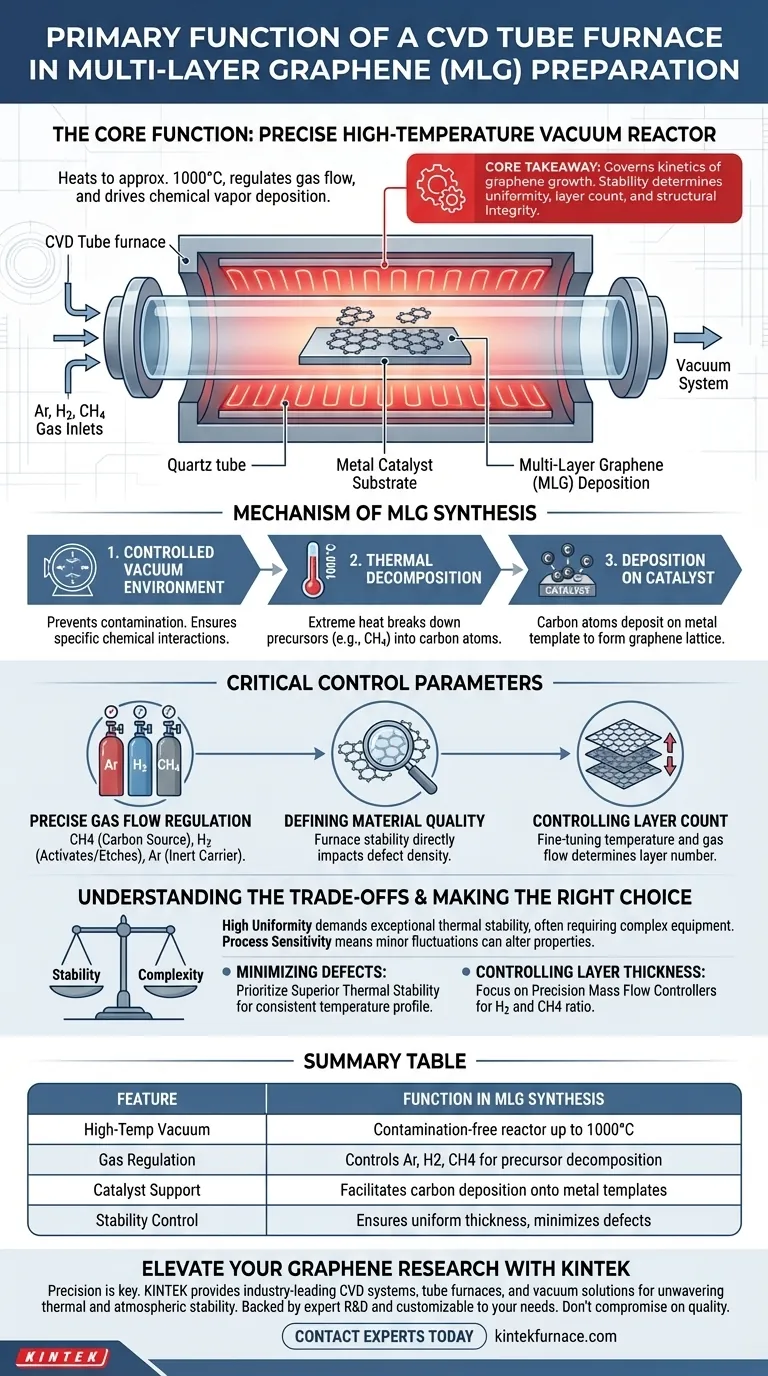

The primary function of a CVD tube furnace in the preparation of Multi-Layer Graphene (MLG) is to provide a precise, high-temperature vacuum environment that drives the chemical vapor deposition process.

It acts as a reactor that heats the system to approximately 1000 °C while regulating the flow of specific gases (Ar, H2, and CH4) to facilitate the decomposition of carbon precursors and their subsequent deposition onto a metal catalyst.

Core Takeaway: The CVD tube furnace is not merely a heating element; it is a precision instrument that governs the kinetics of graphene growth. Its ability to maintain thermal and atmospheric stability is the deciding factor in the uniformity, layer count, and structural integrity of the final MLG material.

The Mechanism of MLG Synthesis

Creating the Reaction Environment

To synthesize MLG, the furnace must establish a controlled vacuum environment.

This isolation prevents contamination and ensures that the chemical interactions occur strictly between the introduced gases and the catalyst substrate.

Thermal Decomposition of Precursors

The furnace operates at high temperatures, typically around 1000 °C.

This extreme heat is required to break down carbon-containing gases, such as methane (CH4). Once decomposed, the carbon atoms are liberated and become available for structural arrangement.

Deposition on Metal Catalysts

The free carbon atoms do not simply float; they deposit onto metal catalyst surfaces placed within the tube.

The catalyst serves as a template, guiding the carbon atoms to arrange themselves into the characteristic hexagonal lattice structure of graphene.

Critical Control Parameters

Precise Gas Flow Regulation

The furnace controls the introduction of specific gas mixtures, including Argon (Ar), Hydrogen (H2), and Methane (CH4).

Methane acts as the carbon source, while Hydrogen often plays a dual role in activating the catalyst and etching away weak carbon bonds to improve quality. Argon serves as an inert carrier gas to maintain pressure and flow dynamics.

Defining Material Quality

The ultimate quality of the MLG depends heavily on the stability of the furnace.

Variations in the internal environment directly impact the defect density, meaning a less stable furnace yields graphene with more structural imperfections.

Controlling Layer Count

The furnace's precision allows researchers to manipulate the layer count of the graphene.

By fine-tuning the temperature and gas flow rates, one can determine whether the resulting material is single-layer graphene or the target Multi-Layer Graphene (MLG).

Understanding the Trade-offs

Stability vs. Complexity

Achieving the high uniformity required for advanced applications (such as ion channels) demands a furnace with exceptional thermal stability.

However, increasing precision often requires more complex and expensive equipment to eliminate thermal gradients along the tube length.

Process Sensitivity

The CVD process is highly sensitive; even minor fluctuations in gas flow or temperature can lead to inconsistent layer thickness.

A lack of precision in the furnace does not just lower quality—it can fundamentally alter the material properties, rendering the MLG unsuitable for its intended application.

Making the Right Choice for Your Goal

To optimize your MLG preparation, you must align your furnace operation with your specific material requirements.

- If your primary focus is minimizing defects: Prioritize a furnace with superior thermal stability to ensure a consistent temperature profile across the catalyst surface.

- If your primary focus is controlling layer thickness: Focus on the precision of the mass flow controllers for H2 and CH4, as the gas ratio heavily influences the deposition rate.

Success in MLG synthesis is less about the maximum temperature reached and more about the unwavering stability of the environment maintained.

Summary Table:

| Feature | Function in MLG Synthesis |

|---|---|

| High-Temp Vacuum | Provides a contamination-free reactor environment up to 1000 °C |

| Gas Regulation | Controls flow of Ar, H2, and CH4 for carbon precursor decomposition |

| Catalyst Support | Facilitates carbon deposition onto metal templates for hexagonal lattice formation |

| Stability Control | Ensures uniform layer thickness and minimizes structural defect density |

Elevate Your Graphene Research with KINTEK

Precision is the deciding factor in the structural integrity of Multi-Layer Graphene. KINTEK provides industry-leading CVD systems, tube furnaces, and vacuum solutions designed to maintain the unwavering thermal and atmospheric stability your research demands.

Backed by expert R&D and precision manufacturing, our lab high-temp furnaces are fully customizable to meet your unique synthesis needs. Don't compromise on material quality—contact our experts today to find the perfect system for your lab.

Visual Guide

References

- Dae Yeop Jeong, Won Il Park. α‐<scp>Al<sub>2</sub>O<sub>3</sub></scp> Networks on <scp>MLG</scp> Membranes for Continuous Lithium Ion Extraction from Artificial Sea Water with Enhanced Selectivity and Durability. DOI: 10.1002/eem2.70145

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are the thermal performance advantages of vacuum tube furnaces? Achieve Faster, Purer Heat Treatment

- Why is MBE Preferred Over Tube Furnaces for 2D Gallium? Achieve Ultra-Pure Atomic Deposition

- How is sealing and atmosphere control achieved in a tube furnace? Master Precise Gas Environments for Your Lab

- What are the advantages of using a tube furnace? Achieve Precise Thermal Control for Your Lab

- What are the advantages of using a tube furnace with nitrogen control for nanoporous carbon? Enhance Your Lab Results

- What is the difference between a vacuum tube furnace and a standard tube furnace? Choose the Right Furnace for Your Lab

- Why is a multi-stage programmable tube furnace necessary for sintering spinel hollow fiber membrane green bodies?

- What is the technical significance of a horizontal tube furnace with a sliding rail for NiOx annealing? Enhance Control