At its core, a tube furnace excels at creating a highly controlled thermal processing environment. Its primary advantages are the ability to maintain precise temperature control, provide a uniform heating zone, and adapt to various atmospheres, from a vacuum to specific inert or reactive gases. This makes it an exceptionally versatile tool for scientific research and specialized industrial applications.

A tube furnace’s true value is not just its ability to get hot, but its capacity to create an isolated, precisely controlled environment. This combination of thermal uniformity and atmospheric control is what makes it indispensable for sensitive material synthesis, testing, and purification.

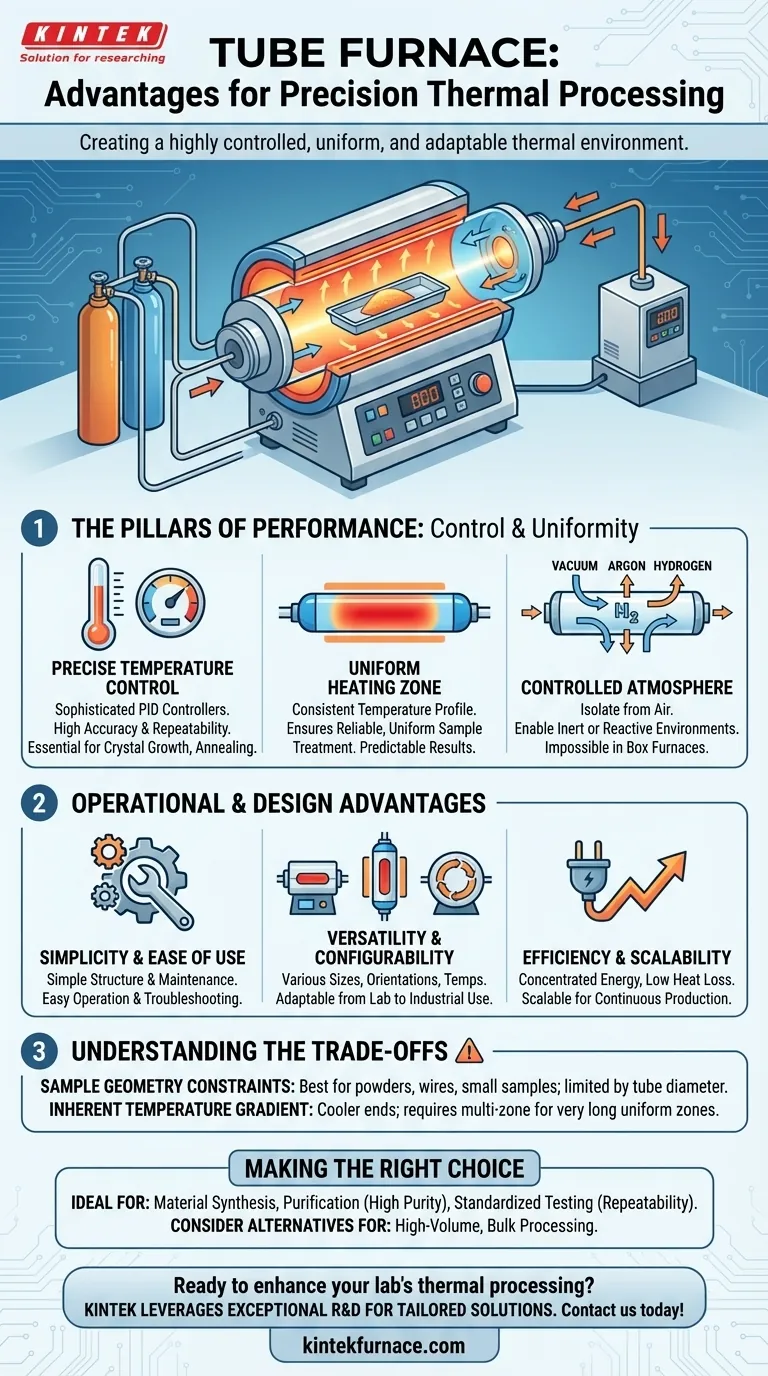

The Pillars of Performance: Control and Uniformity

The most significant benefits of a tube furnace stem from its ability to tightly manage the processing environment, ensuring experiments are both accurate and repeatable.

Achieving Precise Temperature Control

Modern tube furnaces use sophisticated controllers (typically PID controllers) that allow you to set and maintain a specific temperature with very high accuracy.

This level of precision is essential for processes where slight temperature deviations can dramatically alter the outcome, such as in crystal growth, annealing, or catalyst development.

Ensuring a Uniform Heating Zone

By design, a tube furnace creates a central hot zone where the temperature is extremely consistent along its length.

While the ends of the tube are naturally cooler, this gradient allows for a predictable and highly uniform area in the center. This is critical for ensuring that an entire sample receives the exact same thermal treatment, leading to reliable and consistent results.

Creating a Controlled Atmosphere

The sealed tube design is the furnace's defining feature. It allows you to completely isolate the sample from the outside air.

You can then pull a vacuum to remove reactive gases like oxygen or introduce a specific gas—such as argon for an inert environment or hydrogen for a reducing one. This atmospheric control is impossible to achieve in a standard box or muffle furnace.

Operational and Design Advantages

Beyond its core performance, the design and operation of a tube furnace offer practical benefits for both laboratory and industrial settings.

Simplicity and Ease of Use

Tube furnaces have a relatively simple structure consisting of a heating chamber, a ceramic or quartz tube, and a control system.

This straightforward design makes them easy to operate, troubleshoot, and maintain compared to more complex thermal processing systems.

Versatility and Configurability

These furnaces are not one-size-fits-all. They are available in a wide range of sizes, temperature capabilities, and orientations (horizontal, vertical, or rotary).

This configurability allows them to be adapted for countless applications, from processing small powders in a research lab to continuous production of specialized fibers in an industrial setting.

Efficiency and Scalability

The cylindrical heating chamber is highly efficient, concentrating energy directly onto the processing tube, which minimizes heat loss and reduces power consumption.

For larger-scale needs, the technology is mature and scalable. Multiple furnace units can be combined to increase throughput for continuous production, as seen in industries like petrochemicals.

Understanding the Trade-offs

No single piece of equipment is perfect for every task. To make an informed decision, you must recognize the inherent limitations of a tube furnace.

Sample Geometry and Volume

The primary constraint of a tube furnace is the diameter of the tube. It is exceptionally well-suited for processing powders, small wafers, wires, or other samples with a small cross-section.

However, it is impractical for heating large, bulky, or irregularly shaped objects that will not fit within the tube or its uniform hot zone.

The Inherent Temperature Gradient

The cooler temperatures at the ends of the tube, while creating a stable central zone, are a limitation if you need a very long, uniform heating area.

Specialized multi-zone furnaces can mitigate this by using separate heating elements and controllers for different sections, but this adds complexity and cost.

Making the Right Choice for Your Application

Selecting the right furnace depends entirely on your specific goal.

- If your primary focus is material synthesis or purification: A tube furnace is ideal, as its atmospheric control and thermal uniformity are critical for achieving high-purity, consistent results.

- If your primary focus is standardized material testing: The precise temperature control ensures your tests (like annealing or tempering) are repeatable and your data is reliable.

- If your primary focus is high-volume, bulk processing: You may need to consider a larger industrial box or conveyor furnace, as a standard tube furnace's volume is a key limitation.

By understanding these core advantages and limitations, you can confidently determine if a tube furnace is the optimal tool for your specific thermal processing needs.

Summary Table:

| Advantage | Description |

|---|---|

| Precise Temperature Control | Uses PID controllers for accurate, repeatable heating, essential for sensitive processes like crystal growth and annealing. |

| Uniform Heating Zone | Provides consistent temperature in the central hot zone, ensuring reliable and uniform sample treatment. |

| Controlled Atmosphere | Sealed tube design allows for vacuum or specific gas environments (e.g., argon, hydrogen), enabling inert or reactive processing. |

| Ease of Use | Simple design with heating chamber, tube, and controls makes operation, troubleshooting, and maintenance straightforward. |

| Versatility | Available in various sizes, temperatures, and orientations (horizontal, vertical, rotary), adaptable for diverse applications. |

| Efficiency | Cylindrical design minimizes heat loss, reducing power consumption and supporting scalability for industrial use. |

Ready to enhance your lab's thermal processing with a tube furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements. Contact us today to discuss how our tailored solutions can improve your material synthesis, testing, and purification processes!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How does a tube heating furnace facilitate the carbon coating process? Boost Layered Oxide Conductivity

- How do roller kilns and tube furnaces differ in their use of Alumina ceramic tubes? Compare Transport vs. Containment

- How does a vertical tube furnace facilitate the simulation of the industrial sintering process for iron ores?

- What function does a tube furnace serve in the PVT growth of J-aggregate molecular crystals? Mastery of Thermal Control

- What are the material requirements for furnace tubes? Optimize Performance and Safety in High-Temperature Labs