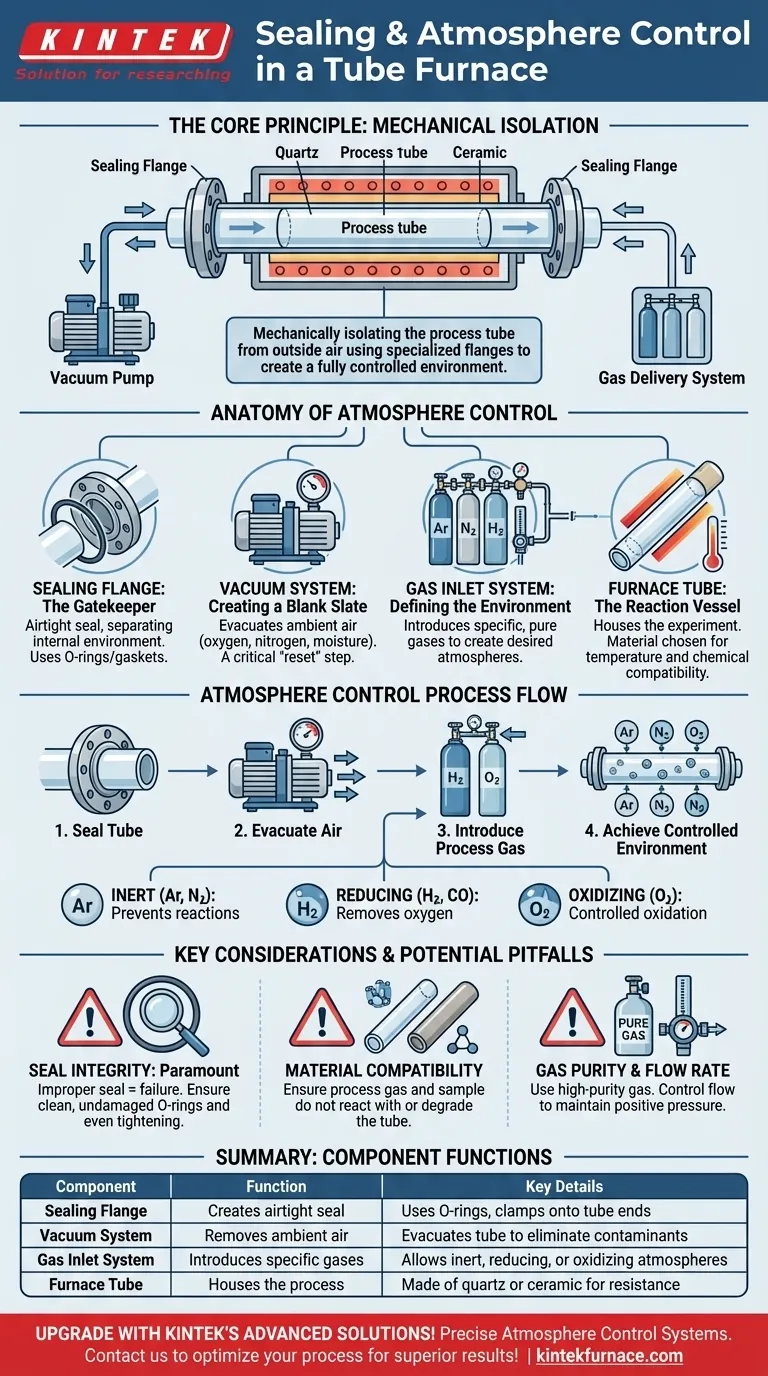

At its core, sealing and atmosphere control in a tube furnace is achieved by mechanically isolating the process tube from the outside air using a specialized sealing flange system. This system allows you to first remove the ambient atmosphere, typically with a vacuum pump, and then introduce a specific, controlled gas to create the precise environment required for your process.

The fundamental principle is not merely to seal the tube, but to create a fully controlled and isolated environment. This is accomplished by using mechanical flanges to seal the tube ends, a vacuum pump to remove unwanted air, and a gas delivery system to introduce a pure, specific atmosphere.

The Anatomy of Atmosphere Control

To understand how a controlled atmosphere is achieved, it's essential to look at the key components and the role each one plays in the system.

The Sealing Flange: The Gatekeeper

A stainless steel sealing flange is the most critical component. It is designed to create an airtight seal at one or both ends of the furnace tube, which is typically made of quartz or a ceramic like corundum.

These flanges are precision-engineered to clamp onto the tube, often using O-rings or other gaskets to ensure a vacuum-tight connection. This mechanical seal is what physically separates the internal process environment from the outside world.

The Vacuum System: Creating a Blank Slate

The flange includes a port connected to a vacuum pump. The first step in most controlled atmosphere processes is to evacuate the tube, removing the ambient air (oxygen, nitrogen, moisture, etc.).

Creating a vacuum serves as a "reset," ensuring that the only gases present are the ones you intentionally introduce. This step is critical for processes that are sensitive to oxidation or contamination.

The Gas Inlet System: Defining the Environment

The flange also features one or more gas inlets. Through these ports, you can introduce a specific gas or gas mixture from an external source.

This allows you to create various atmospheres, such as:

- Inert: Using argon (Ar) or nitrogen (N2) to prevent any chemical reactions.

- Reducing: Using hydrogen (H2) or carbon monoxide (CO) to remove oxygen from a material.

- Oxidizing: Using pure oxygen (O2) for controlled oxidation processes.

The Furnace Tube: The Reaction Vessel

The tube itself, while containing the experiment, is part of the control system. The material—whether quartz glass or a ceramic—is chosen based on the required temperature and its chemical compatibility with the process gas and materials being heated.

Key Considerations and Potential Pitfalls

Achieving a perfect atmosphere is a game of precision. A small oversight can compromise an entire experiment.

Seal Integrity is Paramount

The most common point of failure is an improper seal. Flanges must be tightened evenly, and O-rings must be clean, correctly seated, and undamaged. Even a microscopic leak can allow air to enter the tube, contaminating the atmosphere.

Material Compatibility

You must ensure your process gas and sample materials will not react with or degrade the furnace tube at high temperatures. For example, certain reactive gases may be unsuitable for a quartz tube and require a more robust ceramic like alumina.

Gas Purity and Flow Rate

The success of your process depends on the purity of the gas you introduce. Use high-purity gas sources and ensure your delivery lines are clean. The flow rate must also be controlled to maintain positive pressure and prevent backflow of air.

Making the Right Choice for Your Process

Your approach to atmosphere control should be dictated by your specific experimental goal.

- If your primary focus is preventing oxidation: Your goal is to displace all oxygen by first evacuating the tube and then backfilling it with an inert gas like argon or nitrogen.

- If your primary focus is creating a reducing environment: You must introduce a reducing gas, such as a hydrogen mixture, to actively remove oxides from your sample during the heating process.

- If your primary focus is achieving maximum purity: A cycle of evacuating the chamber and purging it with inert gas multiple times is essential before establishing the final process atmosphere.

Ultimately, mastering atmosphere control is about methodically creating and protecting a perfect, isolated environment for your process to succeed.

Summary Table:

| Component | Function | Key Details |

|---|---|---|

| Sealing Flange | Creates airtight seal | Uses O-rings, clamps onto tube ends |

| Vacuum System | Removes ambient air | Evacuates tube to eliminate contaminants |

| Gas Inlet System | Introduces specific gases | Allows inert, reducing, or oxidizing atmospheres |

| Furnace Tube | Houses the process | Made of quartz or ceramic for temperature and chemical resistance |

Upgrade your lab's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with precise atmosphere control systems. Our product line includes Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization to meet your unique experimental needs. Contact us today to discuss how we can optimize your sealing and atmosphere processes for superior results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab