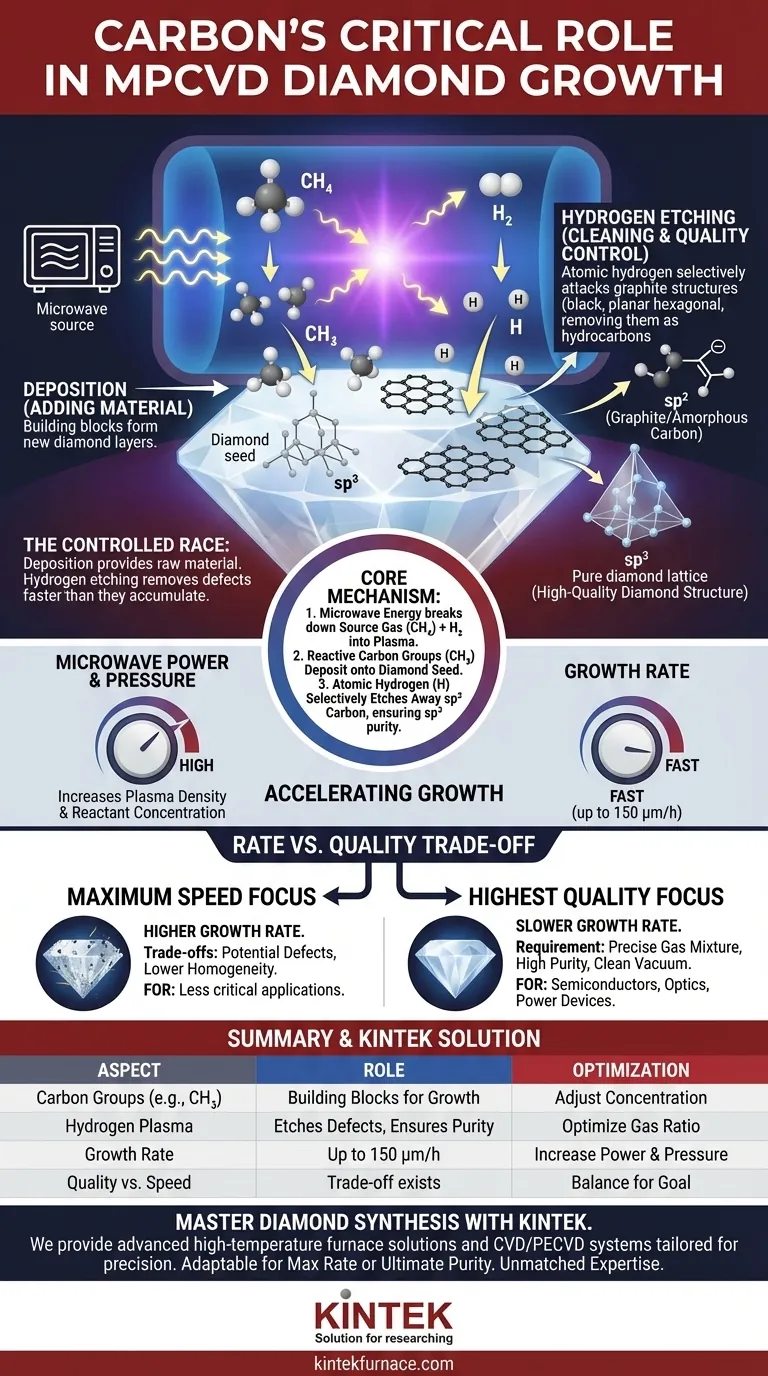

In the MPCVD process, carbon-containing groups like methyl (CH₃) are the fundamental building blocks that deposit onto the diamond seed crystal. Microwave energy breaks down a source gas (like methane) into these reactive carbon groups, which then form new layers. Simultaneously, hydrogen plasma selectively etches away any undesirable non-diamond carbon (like graphite), ensuring that only the high-quality diamond (sp³) structure remains and grows.

The entire process is a carefully controlled race between deposition and purification. Carbon groups provide the raw material for growth, while hydrogen atoms act as a crucial quality control agent, removing defects faster than they can accumulate.

The Core Mechanism: Deposition and Etching

The genius of Microwave Plasma Chemical Vapor Deposition (MPCVD) lies in its ability to perform two opposing actions at the same time: adding material and cleaning it.

Step 1: Creating the Building Blocks

Microwave energy is used to excite a mixture of a carbon-source gas (like methane, CH₄) and hydrogen (H₂) into a plasma.

This intense energy field creates violent collisions between atoms, breaking down the stable gas molecules. This process generates a high density of highly reactive particles, including atomic hydrogen (H) and various carbon-containing groups (CH₃, CH₂, C₂H₂, etc.).

Step 2: The Deposition of Carbon

These newly formed, highly reactive carbon groups are the essential precursors for diamond growth.

They exist in a supersaturated state within the plasma and deposit onto the surface of a prepared diamond seed. This is the "Chemical Vapor Deposition" part of the process, where new atomic layers are added to the crystal.

Step 3: The Critical Role of Hydrogen Etching

This is the most critical phase for ensuring high quality. When carbon groups land on the surface, they can form two types of bonds:

- sp³ bonds: The strong, tetrahedral bonds that create the diamond crystal lattice.

- sp² bonds: The weaker, planar bonds that form graphite or amorphous carbon.

Atomic hydrogen in the plasma is significantly more effective at breaking and removing the undesirable sp² bonds than the stable sp³ diamond bonds. This preferential etching continuously "cleans" the growing surface, leaving behind almost pure diamond.

How to Accelerate Diamond Growth

Controlling the speed of the MPCVD process comes down to managing the density and activity of the reactive particles in the plasma.

Increasing Reactant Density

Increasing the chamber pressure and the input microwave power directly enhances the plasma's intensity.

This leads to a more efficient decomposition of the source gas, which dramatically increases the concentration of both the carbon-containing "building blocks" (like CH₃) and the atomic hydrogen "cleaners."

The Impact on Growth Rate

A higher concentration of these reactive groups at the diamond surface means both deposition and etching happen faster.

With more building blocks available per second, the growth rate can be accelerated significantly. Advanced MPCVD processes can achieve rates up to 150 μm/h, a massive leap from the typical 1 μm/h of older or less optimized methods.

Understanding the Trade-offs: Rate vs. Quality

While high-speed growth is possible, it is not always the primary goal. There is a fundamental trade-off between the rate of growth and the final quality of the diamond crystal.

The Problem with Pure Speed

Pushing for the absolute maximum growth rate can overwhelm the hydrogen etching process. This can lead to the inclusion of defects, lower crystal homogeneity, and limitations on the achievable size of a uniform, single-crystal diamond.

The Purity Imperative for Advanced Applications

For high-precision uses like semiconductors, optics, or power devices, quality is non-negotiable. These applications require near-perfect diamonds with extremely low impurity content and defect density.

Achieving this level of quality demands a slower, more deliberate process using high-purity raw materials and maintaining an impeccably clean vacuum environment to prevent contamination.

The Balancing Act of Gas Mixtures

The ratio of the carbon-source gas to hydrogen is a key control parameter. An optimized gas mixture is essential to balance a healthy growth rate with the plasma's ability to effectively etch away sp² carbon, thereby maintaining high quality.

Making the Right Choice for Your Goal

Your approach to MPCVD should be dictated by your end goal, as the process parameters must be tuned to optimize for either speed or perfection.

- If your primary focus is maximum growth rate: Increase microwave power and chamber pressure to generate the densest possible plasma, but be prepared for potential compromises in crystal uniformity.

- If your primary focus is the highest possible quality: Prioritize precise control over the gas mixture, use exceptionally high-purity materials, and maintain a pristine vacuum, accepting that this will result in a slower growth rate.

Mastering the interplay between carbon deposition and hydrogen etching is the key to successfully synthesizing diamond for any application.

Summary Table:

| Key Aspect | Role in MPCVD Diamond Growth |

|---|---|

| Carbon-Containing Groups (e.g., CH₃) | Act as the fundamental building blocks (precursors) that deposit onto the seed crystal to form new diamond layers. |

| Hydrogen Plasma | Selectively etches away non-diamond (sp²) carbon, ensuring the purity and high quality of the growing diamond structure. |

| Growth Rate (Up to 150 µm/h) | Accelerated by increasing microwave power and pressure to create a denser plasma with more reactive precursors. |

| Quality vs. Speed Trade-off | Maximum speed can introduce defects; highest quality requires slower growth, precise gas mixtures, and a pristine environment. |

Ready to Master Diamond Synthesis in Your Lab?

Understanding the delicate balance between carbon deposition and hydrogen etching is crucial for successful MPCVD. At KINTEK, we empower your research with advanced high-temperature furnace solutions tailored for precision materials synthesis.

Why choose KINTEK for your MPCVD needs?

- Advanced Technology: Our Vacuum & Atmosphere Furnaces and CVD/PECVD Systems are engineered for the precise control required to optimize the deposition-etching balance for high-quality diamond growth.

- Deep Customization: Leveraging our exceptional in-house R&D and manufacturing, we adapt our systems to your unique experimental requirements, whether you prioritize maximum growth rate or ultimate crystal purity.

- Unmatched Expertise: We are your partner in innovation, providing the robust tools needed to push the boundaries of semiconductor, optical, and power device applications.

Don't compromise on your diamond's quality. Let KINTEK provide the reliable, high-performance foundation your breakthrough research demands.

Contact our experts today to discuss how we can customize a solution for your lab!

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- How is MPCVD used in manufacturing polycrystalline diamond optical components? Achieve Superior Optical Performance

- How is MPCVD used in the production of polycrystalline diamond optical components? Discover High-Purity Diamond Growth for Optics

- What factors influence the quality of diamond deposition in the MPCVD method? Master the Critical Parameters for High-Quality Diamond Growth

- In which industries is the microwave plasma chemical vapor deposition system commonly used? Unlock High-Purity Material Synthesis

- What is the relationship between diamond growth rate and quality in the MPCVD method? Balancing Speed and Purity for Your Application