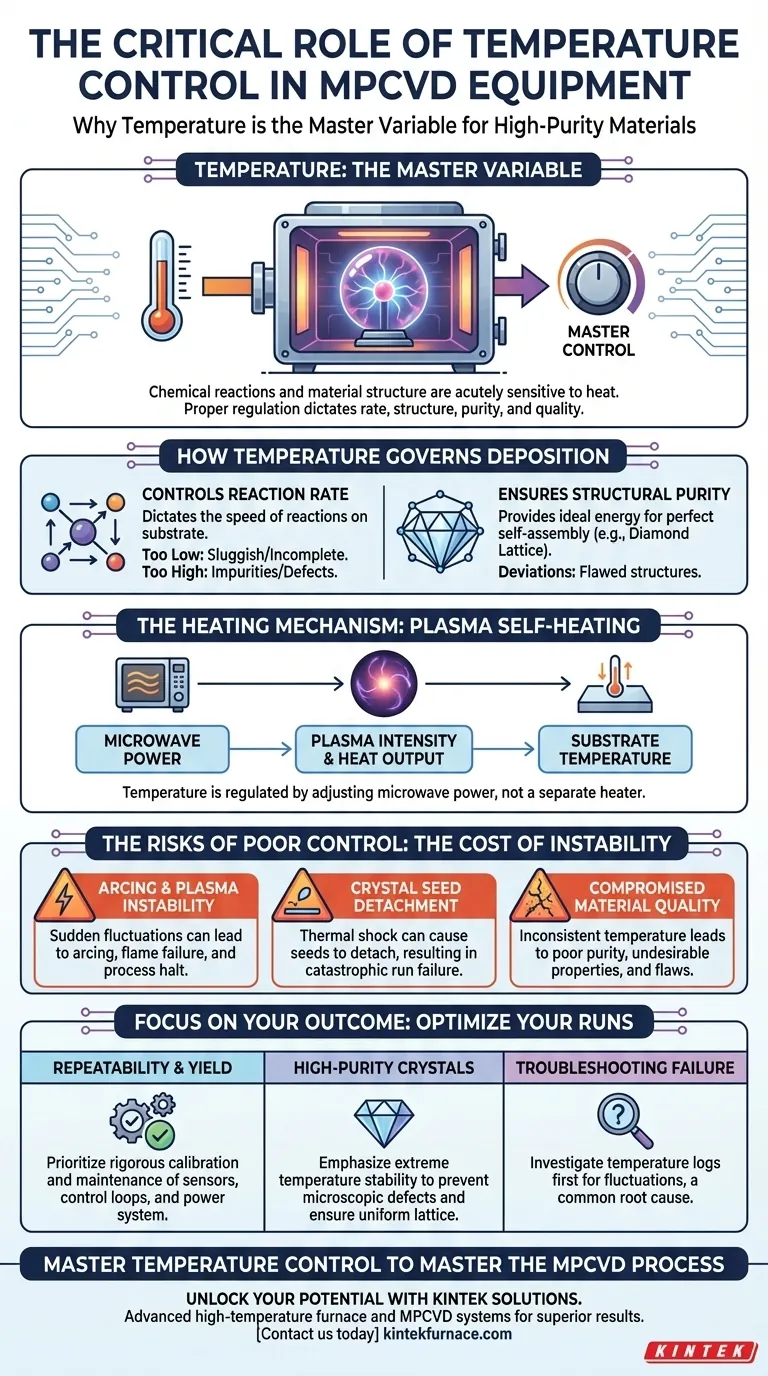

In Microwave Plasma Chemical Vapor Deposition (MPCVD), temperature is not just a parameter; it is the master variable. The temperature control system is critical because the chemical reactions that form the desired material, such as high-purity diamond, are acutely sensitive to heat. Proper temperature regulation directly governs the reaction rate, ensuring the resulting film has the correct structure, purity, and overall quality.

The core challenge in MPCVD is not merely reaching a specific temperature, but maintaining absolute stability. Even minor temperature fluctuations can derail the entire deposition process, leading to flawed materials, inconsistent growth, or catastrophic run failure.

How Temperature Governs Material Deposition

To understand the system's importance, you must first understand how temperature fundamentally controls the growth process. It isn’t simply about being "hot enough"; it's about precision.

Controlling the Rate of Chemical Reactions

The deposition process is a series of complex chemical reactions occurring on the substrate surface. Temperature acts as the primary catalyst, dictating the speed of these reactions.

If the temperature is too low, reactions may be sluggish or incomplete. If it is too high, unwanted side-reactions can occur, introducing impurities or defects into the crystal structure.

Ensuring Structural and Chemical Purity

The goal of MPCVD is often to create a material with a highly specific crystalline structure, like a diamond lattice. Achieving this requires the atoms to arrange themselves perfectly.

A stable and precise temperature provides the ideal energy environment for this self-assembly. Deviations can result in unwanted compounds or a flawed structure, compromising the material's properties.

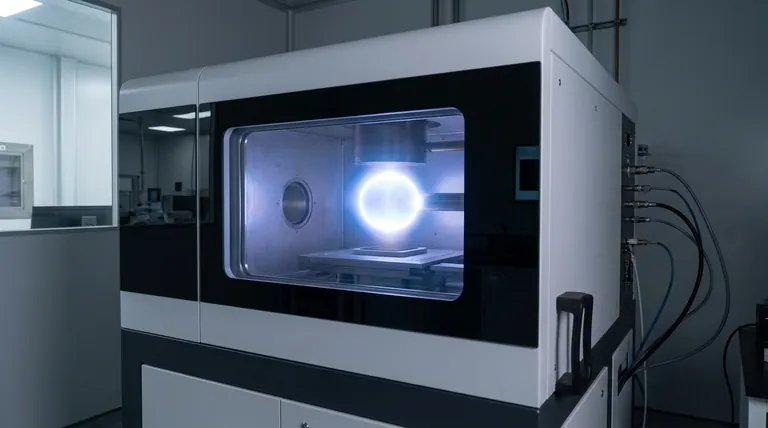

The Heating Mechanism: Plasma Self-Heating

In MPCVD, the substrate is typically heated directly by the microwave plasma itself. This is known as plasma self-heating.

This means that temperature is not controlled by a separate, independent heater in the traditional sense. Instead, temperature is regulated by adjusting the microwave power, which in turn controls the plasma's intensity and heat output.

The Critical Link Between Stability and Success

Because temperature is controlled via microwave power, the stability of one is directly tied to the other. This relationship is central to a successful deposition run.

Preventing Growth Defects

A stable temperature ensures a consistent, uniform growth rate across the substrate. Unstable temperatures can lead to non-uniform layers, internal stresses, and other defects that degrade the final product.

Enabling Smooth Power Adjustment

A well-functioning control system allows for smooth, continuous adjustments to the microwave power. This ensures the reaction temperature remains constant even as growth conditions change slightly over a long deposition run.

Understanding the Risks of Poor Temperature Control

Failure to maintain precise temperature control is not a minor issue; it is a primary cause of failed experiments and low-yield production.

Arcing and Plasma Instability

Sudden changes in process conditions can lead to temperature fluctuations. The control system must react, but if it over- or under-corrects the microwave power, it can destabilize the plasma.

This instability can lead to arcing (electrical discharges) or even flame failure, where the plasma is extinguished, halting the deposition process entirely.

Detachment of Crystal Seeds

In diamond growth, tiny crystal seeds are placed on a substrate to initiate the process. Thermal shock from unstable temperatures can cause these seeds to detach from the substrate.

This is a catastrophic failure, as it results in a complete loss of the run and the valuable seed crystals.

Compromised Material Quality

Even if the process doesn't fail completely, inconsistent temperatures will inevitably lead to a lower-quality material. The final product may have poor purity, undesirable properties, or structural flaws, rendering it useless for its intended application.

Making the Right Choice for Your Process

Understanding the role of temperature allows you to diagnose problems and optimize your runs for specific outcomes.

- If your primary focus is process repeatability and yield: Prioritize the rigorous calibration and maintenance of your temperature sensors, control loops, and microwave power system.

- If your primary focus is growing high-purity single crystals: Emphasize maintaining extreme temperature stability to prevent microscopic defects and ensure uniform lattice formation.

- If your primary focus is troubleshooting a failed deposition: Always investigate the temperature logs first for any fluctuations or deviations, as this is one of the most common root causes of failure.

Mastering temperature control is the foundational step to mastering the MPCVD process itself.

Summary Table:

| Aspect | Importance in MPCVD |

|---|---|

| Reaction Rate Control | Dictates speed and completeness of chemical reactions for proper film formation |

| Structural Purity | Maintains ideal energy for perfect crystalline structures like diamond lattice |

| Plasma Stability | Prevents arcing and flame failure by regulating microwave power |

| Defect Prevention | Ensures uniform growth, reduces internal stresses, and avoids seed detachment |

| Process Reliability | Enables repeatable, high-yield runs with consistent material quality |

Unlock the Full Potential of Your MPCVD Process with KINTEK

Struggling with temperature fluctuations, plasma instability, or inconsistent diamond growth in your MPCVD equipment? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for your needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're focused on high-purity single crystals, process repeatability, or troubleshooting failed depositions, our expertise ensures optimal temperature control for superior results.

Contact us today to discuss how we can enhance your lab's efficiency and achieve flawless material deposition!

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What are some applications of MPCVD? Unlock High-Purity Diamond for Advanced Engineering

- What is the basic principle of operation for the microwave plasma chemical vapor deposition system? Unlock High-Purity Material Growth

- What is the role of inert gas doping in the MPCVD method? Accelerate Single-Crystal Diamond Growth

- How is MPCVD used in the production of polycrystalline diamond optical components? Discover High-Purity Diamond Growth for Optics

- Why is maintaining gas pipelines important in MPCVD equipment? Ensure Purity and Safety in Crystal Growth