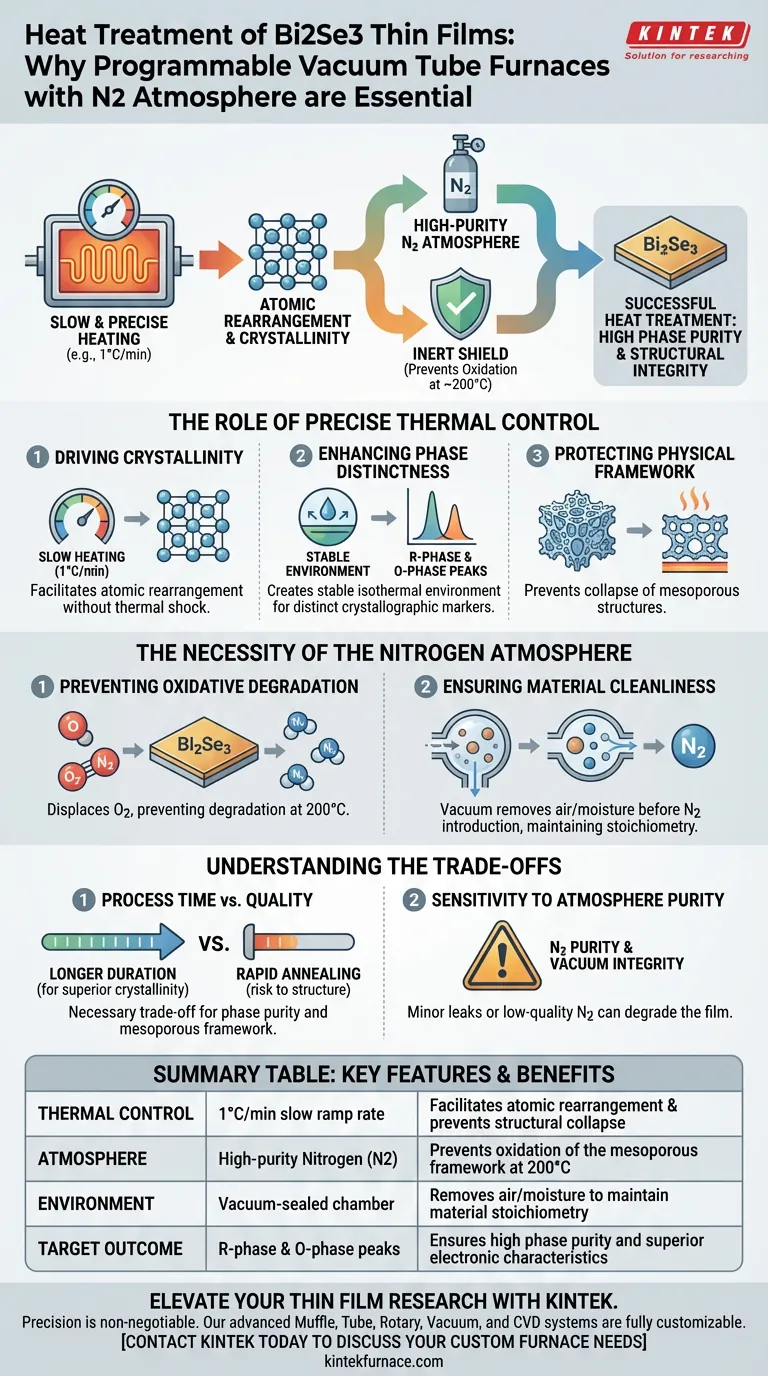

To ensure the successful heat treatment of Bi2Se3 thin films, a programmable vacuum tube furnace with a nitrogen atmosphere is required to strictly control both the thermal ramp rate and the chemical environment. The programmable nature of the furnace enables a slow, precise heating rate (such as 1 °C per minute) to facilitate necessary atomic rearrangement, while the nitrogen atmosphere acts as an inert shield to prevent the material from oxidizing at temperatures around 200 °C.

Core Takeaway The success of this process relies on a delicate balance: you must apply enough heat to organize the crystalline structure, but you must do so in a chemically inert environment to prevent the degradation of the film’s mesoporous framework.

The Role of Precise Thermal Control

Driving Crystallinity through Slow Heating

The primary goal of heat treatment is to improve the crystalline order of the Bi2Se3 material.

A programmable furnace allows for extremely slow heating rates, typically around 1 °C per minute. This gradual introduction of energy is critical for enabling atomic rearrangement without inducing thermal shock.

Enhancing Phase Distinctness

Controlled heating creates a stable isothermal environment.

This stability allows for the clear emergence of distinct crystallographic markers, specifically the R-phase and O-phase peaks. Without this precision, the material may remain amorphous or form irregular crystal structures.

Protecting the Physical Framework

Bi2Se3 thin films often possess a delicate mesoporous physical framework.

Rapid or uncontrolled heating could collapse these porous structures. The programmable furnace ensures the thermal energy is sufficient to improve crystallinity but gentle enough to leave the physical architecture intact.

The Necessity of the Nitrogen Atmosphere

Preventing Oxidative Degradation

At elevated temperatures, such as 200 °C, Bi2Se3 is highly susceptible to reacting with oxygen.

The introduction of high-purity nitrogen (N2) displaces oxygen and creates an inert protective atmosphere. This prevents oxidative degradation, which would chemically alter the film and destroy its intended properties.

Ensuring Material Cleanliness

While the primary reference highlights oxidation prevention, the broader purpose of the vacuum and nitrogen setup is to maintain material cleanliness.

By removing air and moisture via vacuum before introducing nitrogen, the furnace eliminates contaminants that could interfere with the film's stoichiometry. This ensures the final product retains its high-quality electronic and physical characteristics.

Understanding the Trade-offs

Process Time vs. Quality

Using a programmable ramp rate of 1 °C per minute significantly extends the duration of the heat treatment process.

While this yields superior crystallinity and phase purity, it requires a much longer processing time compared to rapid annealing methods. This is a necessary trade-off to preserve the delicate mesoporous structure.

Sensitivity to Atmosphere Purity

The effectiveness of this method is entirely dependent on the purity of the nitrogen gas and the integrity of the vacuum seal.

Even a minor leak or low-quality nitrogen source can introduce enough oxygen to degrade the film at 200 °C. The equipment demands rigorous maintenance to ensure the "inert" environment is truly inert.

Making the Right Choice for Your Goal

To optimize your Bi2Se3 thin film synthesis, consider these specific adjustments:

- If your primary focus is Phase Purity: strictly adhere to the 1 °C/minute heating rate to allow sufficient time for the R-phase and O-phase peaks to develop fully.

- If your primary focus is Structural Integrity: monitor the nitrogen flow rate continuously to ensure positive pressure prevents any oxidation of the mesoporous framework.

Ultimately, the programmable vacuum tube furnace is not just a heater; it is a stabilization chamber that allows delicate atomic restructuring to occur without chemical destruction.

Summary Table:

| Feature | Requirement | Benefit |

|---|---|---|

| Thermal Control | 1 °C/min slow ramp rate | Facilitates atomic rearrangement & prevents structural collapse |

| Atmosphere | High-purity Nitrogen (N2) | Prevents oxidation of the mesoporous framework at 200 °C |

| Environment | Vacuum-sealed chamber | Removes air/moisture to maintain material stoichiometry |

| Target Outcome | R-phase & O-phase peaks | Ensures high phase purity and superior electronic characteristics |

Elevate Your Thin Film Research with KINTEK

Precision is non-negotiable when treating delicate materials like Bi2Se3. Backed by expert R&D and world-class manufacturing, KINTEK provides advanced Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific ramp rate and atmospheric requirements.

Don't let oxidation or thermal shock compromise your results. Let our specialists help you design the perfect high-temperature solution for your lab.

Contact KINTEK Today to Discuss Your Custom Furnace Needs

Visual Guide

References

- Selective Design of Mesoporous Bi<sub>2</sub>Se<sub>3</sub> Films with Orthorhombic and Rhombohedral Crystals. DOI: 10.1002/smll.202501534

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How does a Tube Furnace facilitate precise control during CVD? Master Stoichiometry and Phase Purity

- What are the temperature capabilities of tube furnaces? Find the Perfect Heat for Your Process

- What are the specific functions of nitrogen and oxygen flow within a tube furnace? Optimize Your Diffusion Process

- What are the main characteristics of horizontal tube furnaces? Optimize Your High-Temp Processing with Uniform Heating

- What are the key features of a vertical tube furnace? Maximize Efficiency in High-Temperature Labs

- What are the possible configurations of heated sections in a High Temperature Tube Furnace? Choose the Right Setup for Your Process

- What role does the high-temperature vacuum tube furnace play in SiC/SiC pyrolysis? Essential Chemical Transformation

- What is the role of a two-zone tube furnace in WTe2 synthesis? Master CVD Precision with Thermal Decoupling