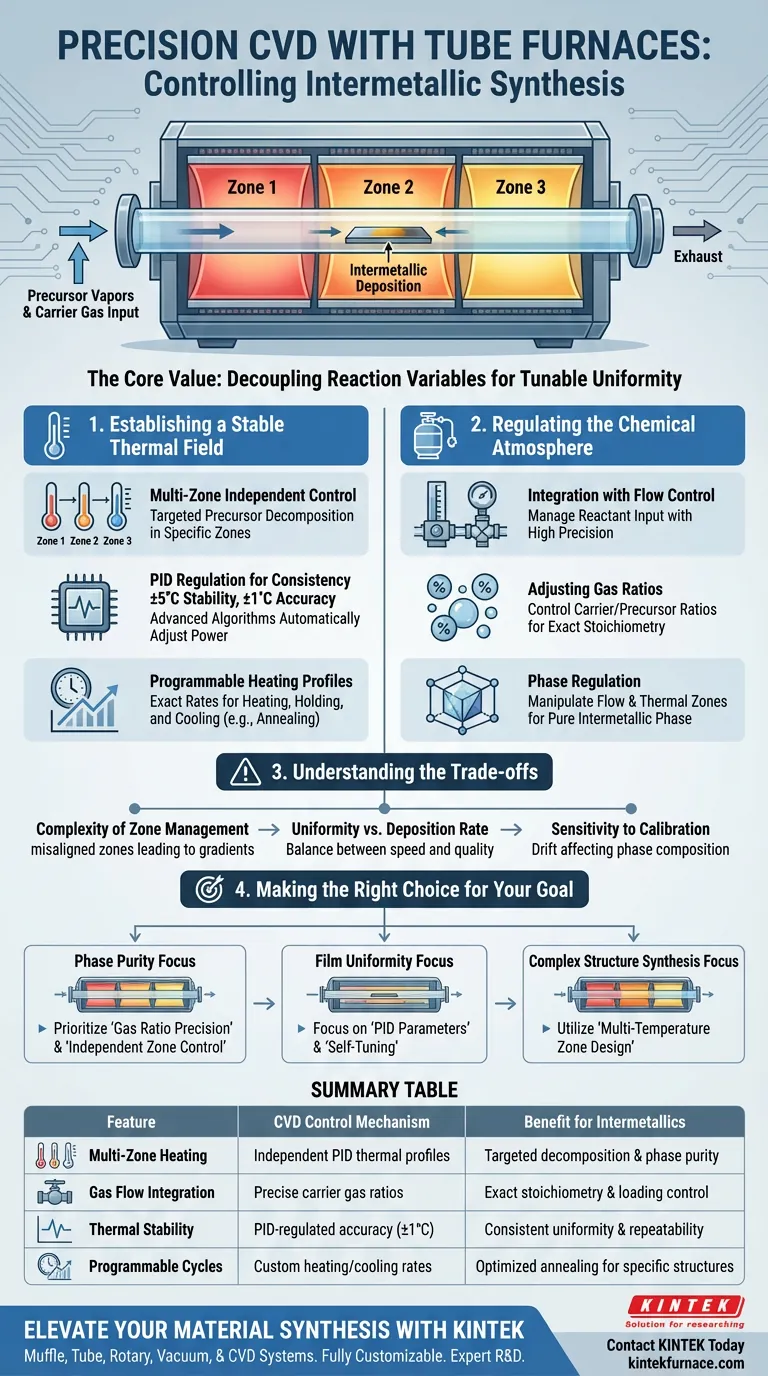

A Tube Furnace facilitates precise control in CVD by acting as a highly stable reaction vessel that integrates multi-zone thermal management with high-precision gas flow regulation. By creating a specific, adjustable thermal field, the furnace ensures that gaseous precursors—such as silane or metal chloride vapors—decompose and deposit only in targeted zones. This architecture allows you to strictly dictate the ratio of carrier gases like hydrogen, enabling exact control over the loading and phase formation of intermetallic compounds.

The core value of a Tube Furnace in CVD is its ability to decouple reaction variables. It provides a stabilized environment where temperature gradients and gas flow rates are managed independently, allowing you to "tune" the chemical phase and uniformity of the deposited material with high repeatability.

Establishing a Stable Thermal Field

Multi-Zone Independent Control

The primary mechanism for precision is the furnace's multi-zone design. Unlike a standard oven, a CVD tube furnace allows you to control different heating zones independently.

Targeted Precursor Decomposition

This zonal control creates a specific thermal profile across the tube. It ensures that precursors decompose only when they reach the specific zone maintained at the reaction temperature.

PID Regulation for Consistency

Advanced systems utilize PID (Proportional-Integral-Derivative) algorithms to automatically adjust heating power. This maintains temperature stability, often within ±5℃, and display accuracy as tight as ±1℃.

Programmable Heating Profiles

You can define exact parameters for heating rates, holding times, and cooling curves. This temporal control is critical for processes like annealing, which may induce specific structural changes or defects required for the material's final properties.

Regulating the Chemical Atmosphere

Integration with Flow Control Systems

Thermal control alone is insufficient for intermetallic compounds; the chemical supply must also be precise. The tube furnace integrates with high-precision flow control systems to manage the input of reactants.

Adjusting Gas Ratios

The system allows for the accurate adjustment of carrier gases, such as hydrogen, relative to the precursor vapors. Mastering this ratio is the key to controlling the stoichiometry of the final compound.

Phase Regulation

By manipulating the flow rate and the thermal zone simultaneously, you control the phase regulation of the material. This ensures the substrate is loaded with the correct intermetallic phase rather than an unwanted byproduct.

Understanding the Trade-offs

Complexity of Zone Management

While multi-zone furnaces offer precision, they introduce complexity. Improper calibration between zones can lead to unintended temperature gradients that skew the deposition profile.

Uniformity vs. Deposition Rate

There is often a balance between the speed of deposition and the quality of the film. pushing for higher flow rates to increase loading can compromise the uniformity and consistency of the thermal field, leading to uneven film thickness.

Sensitivity to Calibration

The high precision of PID controllers and flow systems requires regular calibration. A slight drift in sensor accuracy can significantly alter the phase composition of sensitive intermetallic compounds.

Making the Right Choice for Your Goal

To maximize the effectiveness of your CVD process, align your furnace settings with your specific material objectives:

- If your primary focus is Phase Purity: Prioritize the gas ratio precision and independent zone control to isolate the exact decomposition temperature of your precursors.

- If your primary focus is Film Uniformity: Focus on the PID parameters and self-tuning technologies to ensure the thermal field remains stable (±5℃) throughout the entire reaction zone.

- If your primary focus is Complex Structure Synthesis: Utilize a multi-temperature zone design to create distinct heating and annealing stages within a single pass.

True precision in CVD comes from viewing the Tube Furnace not just as a heater, but as a programmable flow reactor.

Summary Table:

| Feature | CVD Control Mechanism | Benefit for Intermetallics |

|---|---|---|

| Multi-Zone Heating | Independent PID thermal profiles | Targeted precursor decomposition & phase purity |

| Gas Flow Integration | Precise carrier gas ratios | Exact control over stoichiometry and loading |

| Thermal Stability | PID-regulated accuracy (±1℃) | Consistent film uniformity and repeatability |

| Programmable Cycles | Custom heating/cooling rates | Optimized annealing for specific crystal structures |

Elevate Your Material Synthesis with KINTEK

Precise CVD processes demand the highest standards of thermal and atmospheric control. At KINTEK, we bridge the gap between complex research requirements and reliable industrial performance.

Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which are fully customizable to meet your unique intermetallic compound research or production needs. Whether you require advanced multi-zone independent control or high-precision gas delivery, our systems provide the stability and repeatability your lab deserves.

Ready to optimize your deposition profiles?

Contact KINTEK Today to discuss your custom furnace requirements with our technical specialists.

Visual Guide

References

- Zhiquan Hou, Hongxing Dai. Exploring Intermetallic Compounds: Properties and Applications in Catalysis. DOI: 10.3390/catal14080538

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What role does a tube furnace play in the physical synthesis of metal nanoparticles? Master Phase Transformation

- What is the primary use of a laboratory tube furnace in biomass carbonization processes? Precision Biochar Engineering

- What are the key heat treatment processes performed in horizontal furnaces? Master Annealing, Hardening, and More

- How is the quartz tube furnace constructed for vacuum operations? Discover Key Design Elements for High-Temperature Vacuum Processing

- What core functions does an argon atmosphere tube furnace perform? Optimize Al-PTFE FGM Sintering

- What role does a tube furnace play in the preparation of biochar-filled PVC composite precursors? Expert Synthesis Guide

- What is the primary function of a tube furnace in contact transfer epitaxy? Powering Precision Perovskite Growth

- How does a tube furnace facilitate the carbonization of ZIFs while preventing oxidation? Expert Insights