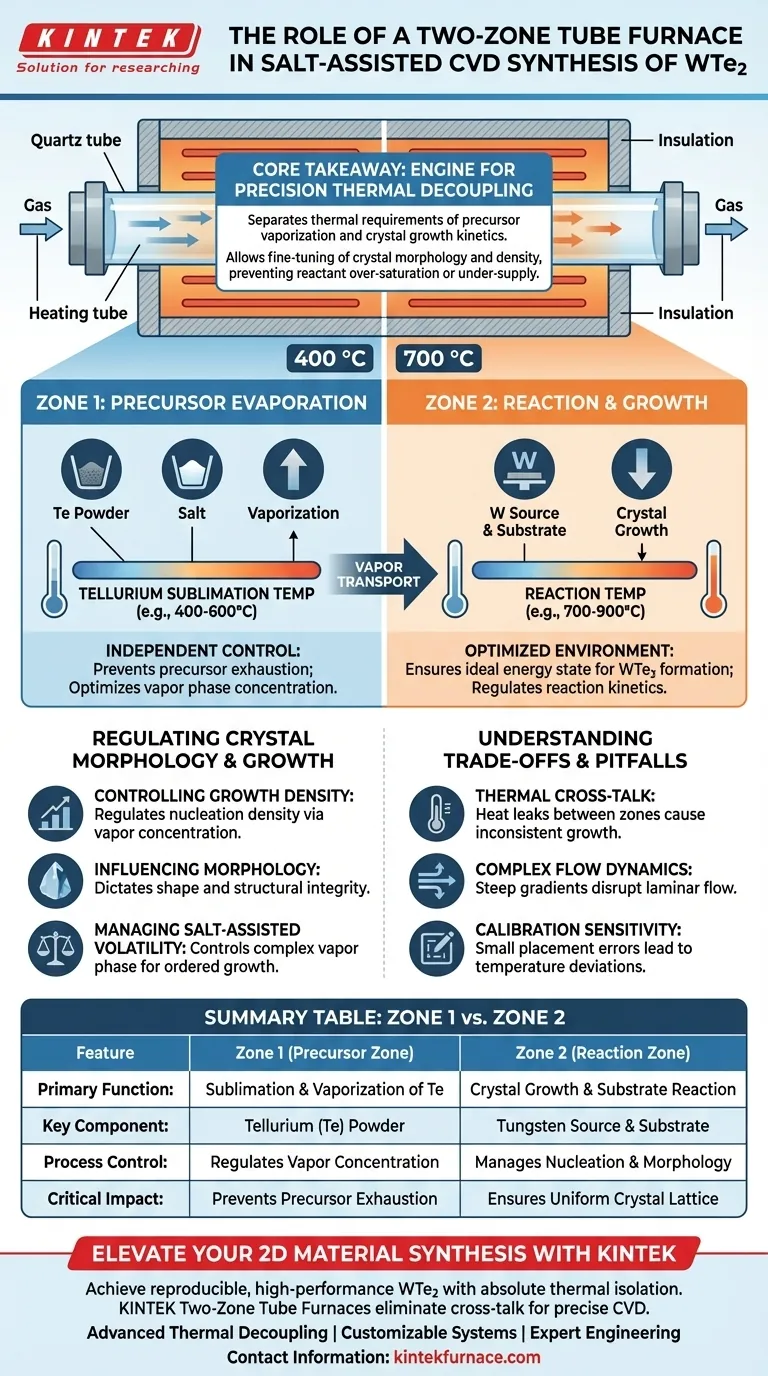

In the synthesis of tungsten ditelluride (WTe2), a two-zone tube furnace serves as the engine for precision thermal decoupling. This configuration allows researchers to independently manage the evaporation temperature of tellurium precursors and the reaction temperature of the tungsten-substrate zone. By isolating these thermal environments, the system provides the exact control over vapor phase concentration and reaction kinetics required to produce high-quality 2D crystals.

The Core Takeaway: A two-zone furnace is essential for WTe2 synthesis because it separates the thermal requirements of precursor vaporization from the kinetics of crystal growth. This independence allows for the fine-tuning of crystal morphology and growth density, preventing the over-saturation or under-supply of reactants.

Decoupling the Evaporation and Reaction Phases

Independent Control of Precursor Vaporization

In the first zone, the tellurium (Te) powder is heated to its specific sublimation temperature. Because tellurium has a different thermal requirement than the tungsten source, this independent zone prevents the precursor from exhausting too quickly or failing to vaporize.

Optimizing the Reaction Environment

The second zone contains the tungsten source and the substrate, maintained at a distinct temperature gradient optimized for chemical bonding. This ensures that when the tellurium vapor arrives, the substrate environment is at the ideal energy state to facilitate the formation of WTe2.

Regulating Chemical Reaction Kinetics

By adjusting the temperature delta between the two zones, operators can control the speed of the chemical transformation. This precise management of reaction kinetics is what determines whether the resulting material is a continuous film or isolated flakes.

Regulating Crystal Morphology and Growth

Controlling Growth Density

The concentration of tellurium vapor reaching the substrate is a direct function of the temperature in the first zone. Precise zoning allows for the regulation of nucleation density, ensuring that crystals do not overlap or aggregate in an uncontrolled manner.

Influencing Crystal Morphology

The temperature in the reaction zone dictates the final shape and structural integrity of the WTe2. Consistent thermal management across the substrate ensures uniform morphology, which is critical for the electronic properties of the material.

Managing Salt-Assisted Volatility

In salt-assisted CVD, the salt lowers the melting point of metal precursors or increases their volatility. The two-zone furnace manages the resulting complex vapor phase, ensuring that the increased reactivity provided by the salt does not lead to disordered growth.

Understanding the Trade-offs and Pitfalls

The Risk of Thermal Cross-Talk

A common challenge in two-zone setups is thermal interference, where heat from the higher-temperature zone leaks into the lower-temperature zone. This can cause the precursor to evaporate faster than intended, leading to inconsistent growth results.

Complexities in Flow Dynamics

Because the two zones create a temperature gradient, they also influence the gas flow dynamics within the tube. If the gradient is too steep, it can create turbulence that disrupts the laminar flow of precursors, resulting in non-uniform deposition across the substrate.

Calibration and Placement Sensitivity

The physical distance between the two zones and the placement of the precursors is high-stakes. Small errors in crucible positioning can lead to significant deviations in the actual temperature experienced by the materials versus the temperature recorded by the furnace sensors.

Applying This Setup to Your Synthesis Goals

To achieve the best results with a two-zone furnace, you must align your temperature profiles with your specific material requirements.

- If your primary focus is large-area uniformity: Maintain a stable, lower evaporation temperature in Zone 1 to ensure a slow, steady supply of tellurium vapor over a longer growth period.

- If your primary focus is high nucleation density: Increase the temperature of Zone 1 relative to Zone 2 to create a supersaturated vapor environment that encourages many small growth sites.

- If your primary focus is high crystallinity and purity: Prioritize the precise temperature of Zone 2 to provide sufficient thermal energy for atoms to arrange into a perfect lattice structure.

Mastering the independent thermal gradients of a two-zone furnace is the definitive path to achieving reproducible, high-performance WTe2 nanosheets.

Summary Table:

| Feature | Zone 1 (Precursor Zone) | Zone 2 (Reaction Zone) |

|---|---|---|

| Primary Function | Sublimation & Vaporization of Te | Crystal Growth & Substrate Reaction |

| Key Component | Tellurium (Te) Powder | Tungsten Source & Substrate |

| Process Control | Regulates Vapor Concentration | Manages Nucleation & Morphology |

| Critical Impact | Prevents Precursor Exhaustion | Ensures Uniform Crystal Lattice |

Elevate Your 2D Material Synthesis with KINTEK

High-performance tungsten ditelluride (WTe2) requires more than just heat; it requires absolute thermal isolation. KINTEK provides industry-leading Two-Zone Tube Furnaces specifically engineered to eliminate thermal cross-talk and deliver the precise gradients necessary for salt-assisted CVD.

Why choose KINTEK for your lab?

- Advanced Thermal Decoupling: Independent control systems to manage disparate vaporization and reaction temperatures.

- Customizable Systems: Backed by expert R&D, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to your unique research requirements.

- Expert Engineering: Our furnaces are designed for laminar flow stability and precise crucible positioning.

Ready to achieve reproducible, high-purity results? Contact KINTEK today to discuss your custom furnace needs." Form)!"

Visual Guide

References

- Andrejs Terehovs, Gunta Kunakova. Chemical Vapor Deposition for the Fabrication of WTe<sub>2</sub>/h‐BN Heterostructures. DOI: 10.1002/admi.202500091

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents