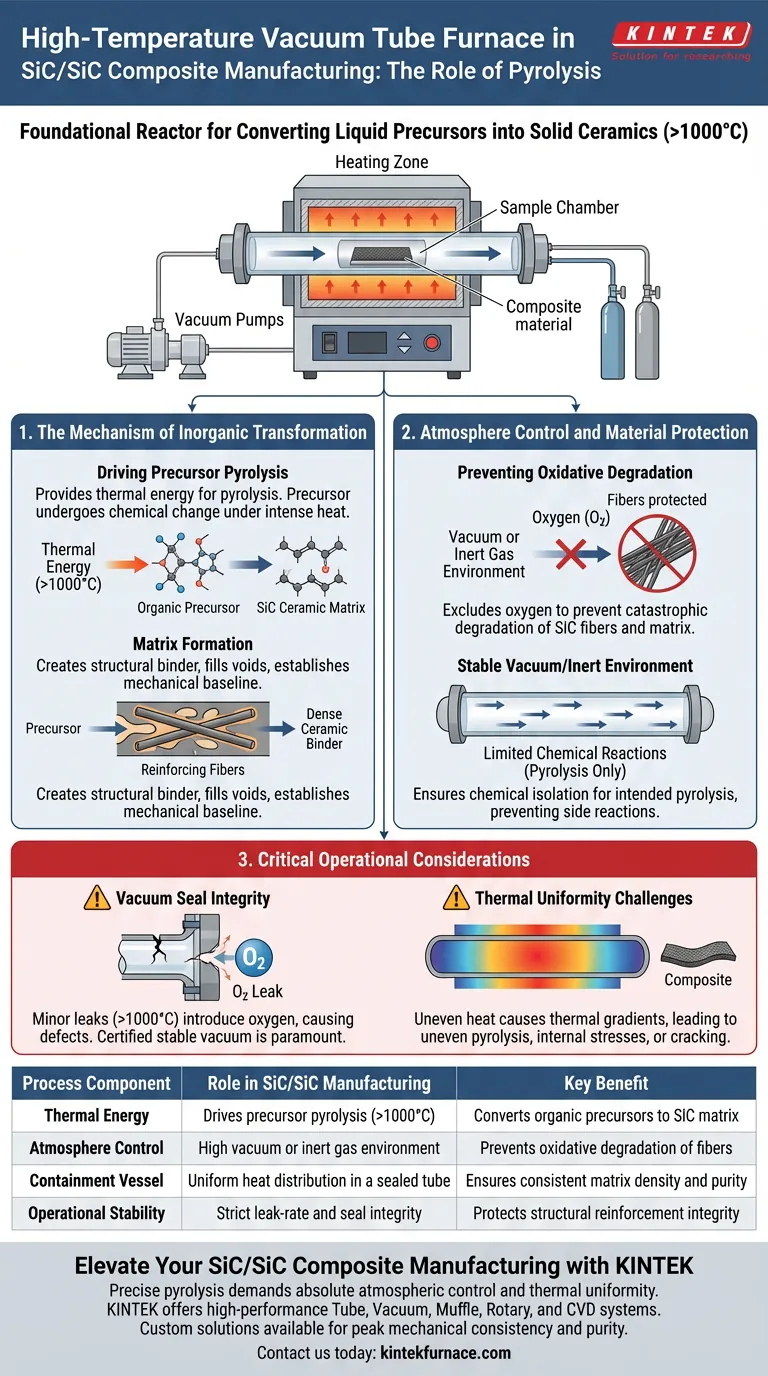

The high-temperature vacuum tube furnace serves as the foundational reactor for converting liquid precursors into solid ceramics. In the context of SiC/SiC composite manufacturing, this equipment drives the pyrolysis stage by sustaining temperatures exceeding 1000°C. Its primary function is to facilitate the inorganic transformation of the precursor while utilizing a vacuum or inert atmosphere to protect the material integrity.

The furnace solves the critical dual challenge of high-temperature processing: it forces the chemical conversion of the precursor into a silicon carbide matrix while simultaneously establishing an oxygen-free environment that prevents the catastrophic degradation of the reinforcing fibers.

The Mechanism of Inorganic Transformation

Driving Precursor Pyrolysis

The central role of the furnace is to provide the thermal energy required for pyrolysis.

The system must reach and maintain temperatures exceeding 1000°C.

Under this intense heat, the solidified precursor undergoes a chemical change, transitioning from an organic state into the desired silicon carbide ceramic matrix.

Matrix Formation

This thermal treatment creates the structural binder of the composite.

The furnace ensures the precursor effectively fills the voids between fibers and hardens into a dense ceramic.

This process establishes the mechanical baseline for the final composite material.

Atmosphere Control and Material Protection

Preventing Oxidative Degradation

The most specific value of using a vacuum tube furnace is its ability to exclude oxygen.

At elevated temperatures, silicon carbide fibers and the newly forming matrix are highly susceptible to oxidation.

Without strict atmosphere control, oxygen would attack the fibers, destroying the composite's structural reinforcement before it is fully formed.

Stable Vacuum or Inert Environment

The furnace creates a "protection environment" using either a high vacuum or an inert gas flow.

This isolation is not merely a feature; it is a chemical necessity for the survival of the material.

It ensures that the chemical reactions occurring inside the tube are strictly limited to the intended pyrolysis, without side reactions caused by air contaminants.

Critical Operational Considerations

The Risk of Atmosphere Compromise

While these furnaces are designed for protection, the integrity of the vacuum seal is paramount.

Even a minor leak during the >1000°C ramp phase can introduce oxygen, leading to surface defects or fiber embrittlement.

Operators must ensure the vacuum levels are certified stable before initiating the heating cycle.

Thermal Uniformity Challenges

A high temperature alone is insufficient; the heat must be applied uniformly across the composite.

Although the primary reference highlights the temperature magnitude, general furnace physics dictates that thermal gradients can cause uneven pyrolysis.

If the tube does not maintain a uniform temperature field, the matrix may density unevenly, leading to internal stresses or cracking within the composite.

Ensuring Process Success

To maximize the effectiveness of the pyrolysis stage, align your furnace operation with your specific manufacturing metrics:

- If your primary focus is Material Purity: Prioritize the vacuum pump capability and leak rate integrity to ensure absolute exclusion of oxygen and contaminants.

- If your primary focus is Mechanical Consistency: Focus on the furnace’s heating zone length and thermal uniformity to guarantee the precursor transforms evenly across the entire part.

The high-temperature vacuum tube furnace is not just a heater; it is the containment vessel that makes the chemistry of SiC/SiC composites possible.

Summary Table:

| Process Component | Role in SiC/SiC Manufacturing | Key Benefit |

|---|---|---|

| Thermal Energy | Drives precursor pyrolysis (>1000°C) | Converts organic precursors to SiC matrix |

| Atmosphere Control | High vacuum or inert gas environment | Prevents oxidative degradation of fibers |

| Containment Vessel | Uniform heat distribution in a sealed tube | Ensures consistent matrix density and purity |

| Operational Stability | Strict leak-rate and seal integrity | Protects structural reinforcement integrity |

Elevate Your SiC/SiC Composite Manufacturing with KINTEK

Precise pyrolysis requires more than just heat—it demands absolute atmospheric control and thermal uniformity. Backed by expert R&D and manufacturing, KINTEK offers high-performance Tube, Vacuum, Muffle, Rotary, and CVD systems tailored for the rigorous demands of advanced ceramic processing. Whether you need a standard setup or a fully customizable high-temperature furnace for unique research needs, our technology ensures your materials achieve peak mechanical consistency and purity.

Ready to optimize your lab's thermal processing? Contact us today to find your solution!

Visual Guide

References

- Surface Processing and Characterization of Stoichiometry-Varied BaZrS<sub>3</sub> Thin Films. DOI: 10.1021/acsaem.5c01766

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is the primary role of a tube furnace in CuGaO2 treatment? Enhance Crystallization and Film Performance

- What types of gases can be introduced into the 3-Zone tube furnace? Optimize Your Process with the Right Atmosphere

- What is the material of the anode in a vacuum tube? Choosing the Right Metal for Power & Performance

- How does a high-temperature tube furnace ensure magnesium alloy scaffold performance? Expert Sintering Guide

- What role does a tube furnace play in the high-temperature heat treatment of vermiculite? Precision Control Expert

- What advantages does a drop tube furnace offer over other types of furnaces? Unlock Precision in Particle Thermal Analysis

- How does the hydrogen reduction process in a laboratory tube furnace facilitate the exsolution of nickel species?

- Can a quartz tube furnace be used for melting materials? Unlock Precise Melting with Visual Control