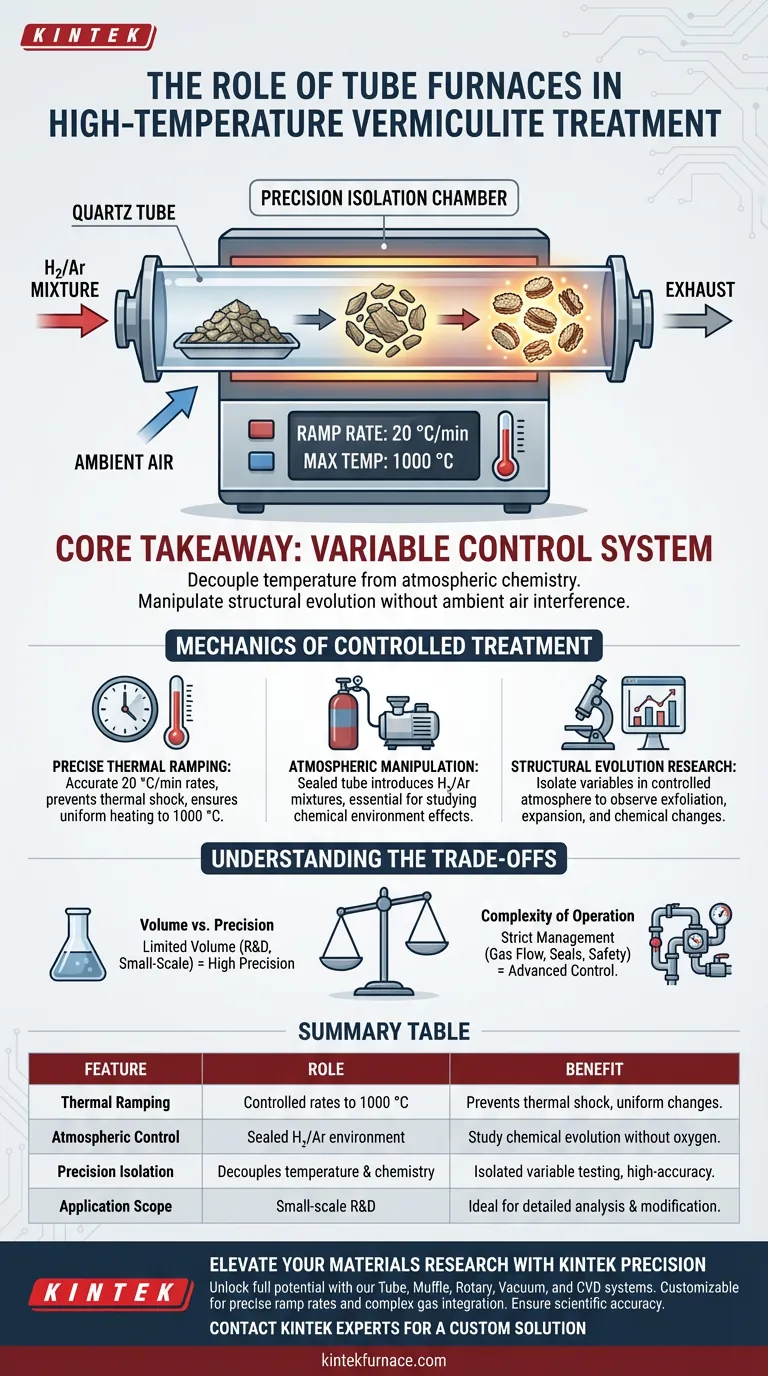

The tube furnace acts as a precision isolation chamber for the high-temperature treatment of vermiculite, going far beyond simple heating. It creates a sealed environment that allows you to ramp temperatures accurately (e.g., 20 °C/min) up to 1000 °C while simultaneously introducing specific gas mixtures, such as Hydrogen and Argon. This combination of thermal precision and atmospheric control is critical for studying how vermiculite's structure evolves under strict chemical conditions.

Core Takeaway: The tube furnace is not just a heat source; it is a variable control system. Its primary value in vermiculite treatment is the ability to decouple temperature from atmospheric chemistry, allowing you to manipulate the material's structural evolution without the interference of ambient air.

The Mechanics of Controlled Treatment

Precise Thermal Ramping

For vermiculite, the rate at which heat is applied is often as important as the maximum temperature itself.

A tube furnace utilizes an accurate control system to manage heating rates, such as a steady 20 °C per minute. This prevents thermal shock and ensures the material reaches its target temperature of 1000 °C uniformly.

Atmospheric Manipulation

The defining feature of this equipment is its sealed tube structure.

Unlike open-air ovens, a tube furnace allows you to introduce reducing gases, specifically H2/Ar (Hydrogen/Argon) mixtures. This capability is essential for researchers investigating how the chemical environment alters the vermiculite’s properties during heating.

Structural Evolution Research

The ultimate goal of using this specific furnace type is to observe structural changes.

By maintaining a constant high-temperature environment under a controlled atmosphere, researchers can isolate specific variables. This enables the detailed study of how vermiculite exfoliates, expands, or chemically alters when exposed to heat in the absence of oxygen or in the presence of reducing agents.

Understanding the Trade-offs

Volume vs. Precision

While tube furnaces offer superior control, they are generally limited in volume.

They are ideal for research, small-scale synthesis, and "day-to-day" lab operations, but they are rarely suitable for high-throughput industrial bulk processing. You are trading batch size for environmental exactness.

Complexity of Operation

Achieving the benefits of a tube furnace requires strict management of ancillary systems.

To utilize the H2/Ar capabilities, you must manage gas flow rates, vacuum seals, and safety protocols for handling reducing gases. This adds a layer of operational complexity compared to standard muffle furnaces.

Making the Right Choice for Your Goal

To maximize the utility of a tube furnace for vermiculite, align your setup with your specific research objectives:

- If your primary focus is Structural Modification: Prioritize the gas flow system to utilize H2/Ar mixtures, as the chemical atmosphere will drive the structural evolution more than heat alone.

- If your primary focus is Basic Exfoliation: Ensure your controller is programmed for precise ramp rates (20 °C/min) to prevent inconsistent expansion, even if you are not using complex gas mixtures.

By leveraging the sealed nature of the tube furnace, you transform a standard heating procedure into a controlled scientific experiment.

Summary Table:

| Feature | Tube Furnace Role in Vermiculite Treatment | Benefit for Researchers |

|---|---|---|

| Thermal Ramping | Controlled rates (e.g., 20 °C/min) up to 1000 °C | Prevents thermal shock; ensures uniform structural changes |

| Atmospheric Control | Sealed environment for H2/Ar gas mixtures | Enables study of chemical evolution without oxygen interference |

| Precision Isolation | Decouples temperature from ambient chemistry | Allows for isolated variable testing and high-accuracy results |

| Application Scope | Small-scale synthesis and R&D operations | Ideal for detailed material analysis and structural modification |

Elevate Your Materials Research with KINTEK Precision

Unlock the full potential of your vermiculite studies with our industry-leading thermal solutions. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems tailored for the most demanding lab environments.

Whether you require precise ramp rates or complex gas integration for atmospheric manipulation, our high-temperature furnaces are fully customizable to meet your unique research needs. Ensure scientific accuracy and repeatable results today.

Contact KINTEK Experts for a Custom Solution

Visual Guide

References

- Ayoub Lahchich, Celia Marcos. Heat Treatment at 1000 °C under Reducing Atmosphere of Commercial Vermiculites. DOI: 10.3390/min14030232

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How does the work process of a quartz tube furnace typically proceed? Master Precision Heating for Advanced Materials

- How does the use of a tube furnace for nitrogen-protected annealing affect tin oxide catalysts? Unlock Superior Activity

- How does a fixed-bed reactor system simulate complex flue gas environments? Optimize Mercury Adsorption Testing

- How to clean a tubular furnace? A Step-by-Step Guide to Safe and Effective Maintenance

- Why is a horizontal electric furnace ideal for small-diameter samples? Achieve Superior Uniform Heating

- What critical conditions does a tube furnace provide for Cu-Fe-NC-3 pyrolysis? Achieve Precision Catalyst Synthesis

- What are the common uses of vertical fluidized bed tube furnaces in laboratory research? Discover Precision Thermal Solutions

- What is the specific role of a Tube Furnace in the synthesis of sodium cobalt borate (NCBO)? Achieve Pure Crystals