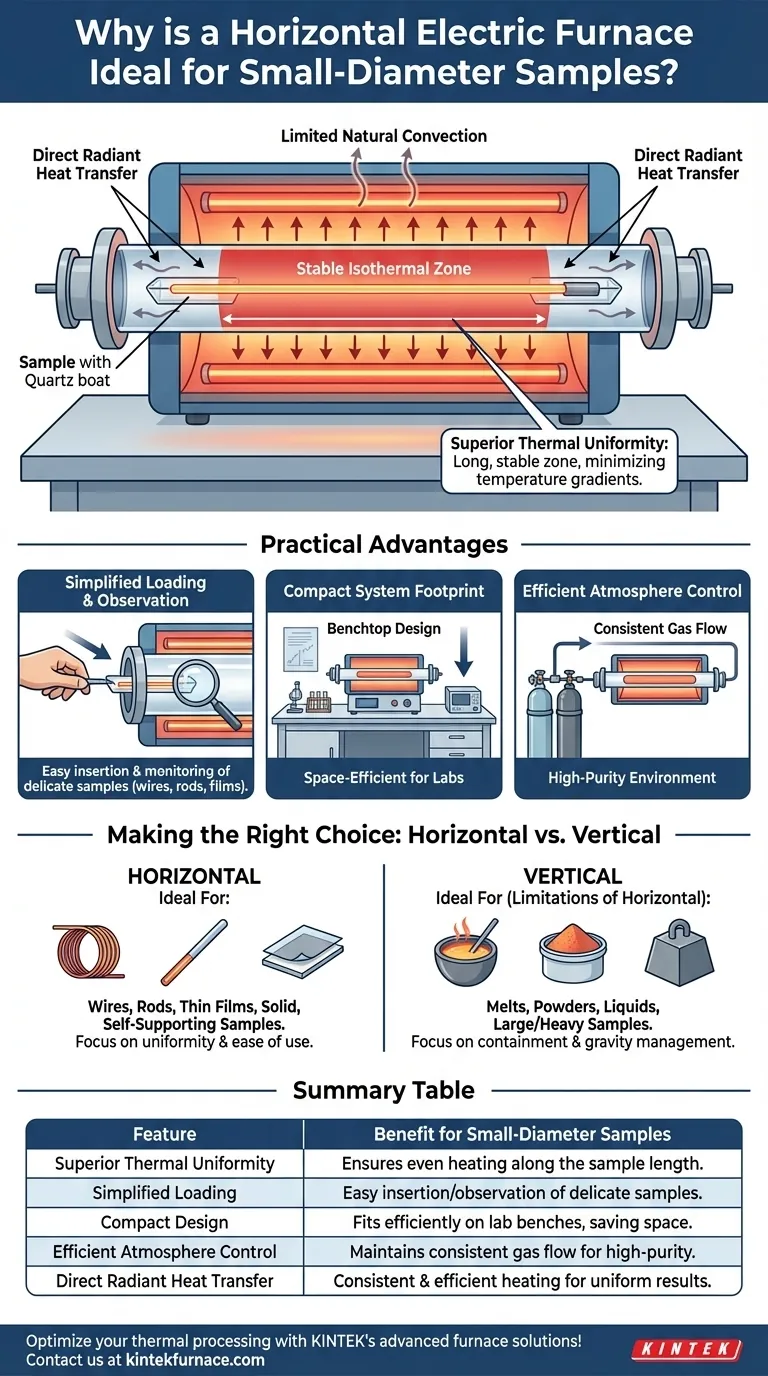

When working with small-diameter samples, a horizontal electric furnace is the ideal choice due to its inherent design advantages. This orientation provides superior thermal uniformity along the length of the workpiece, simplifies the loading and observation of delicate samples, and allows for a more compact and efficient system design on a standard lab bench.

The decision between a horizontal and vertical furnace is fundamentally about matching heat transfer physics to the sample's geometry. For long, thin samples, a horizontal furnace offers the most direct and uniform thermal exposure, minimizing temperature gradients that can compromise process integrity.

The Physics of Uniform Heating

To understand why horizontal furnaces excel, we must look at how they transfer heat. The goal of any advanced thermal process is to create a predictable and highly uniform temperature environment, known as an isothermal zone.

Direct Radiant Heat Transfer

In a typical horizontal tube furnace, the heating elements surround the process tube. This arrangement provides a direct line-of-sight for thermal radiation to hit the sample's surface uniformly along its entire length. For a small-diameter sample, this direct radiation is exceptionally efficient and consistent.

Minimizing Convective Interference

Heat also moves through convection—the circulation of hot gas. In a narrow horizontal tube, natural convection is inherently limited. While hot gas rises, its movement is constrained by the tube's ceiling, resulting in a more stable and predictable thermal environment. This contrasts with vertical furnaces, where convection can create a significant temperature difference between the top and bottom of the chamber.

Creating a Stable Isothermal Zone

The combination of direct radiation and minimal convection allows horizontal furnaces to establish long, stable isothermal zones. This is critical for applications like annealing wires, crystal growth, or sensor calibration, where the entire length of the sample must experience the exact same temperature for a successful outcome.

Practical Advantages for Small Samples

Beyond the thermal physics, horizontal furnaces offer significant operational benefits, especially in a research or small-scale production environment.

Simplified Loading and Observation

Sliding a small sample, such as a thin rod, a substrate with a film, or a sample held in a quartz boat, into a horizontal tube is simple and safe. This design also makes it much easier to visually monitor the sample during the process, which is often impossible in a top-loading vertical furnace.

Compact System Footprint

Horizontal furnaces are typically designed to sit on a workbench, requiring minimal vertical clearance. This makes them exceptionally space-efficient for crowded labs. Their design integrates well with gas delivery and vacuum systems, creating a self-contained and accessible processing station.

Efficient Atmosphere Control

Controlling the gas environment is often crucial. A horizontal tube provides a simple, linear path for purging air and introducing process gases like nitrogen or argon. This makes it easy to achieve a consistent flow and maintain a high-purity atmosphere across the entire sample.

Understanding the Trade-offs

A horizontal furnace is not a universal solution. Acknowledging its limitations is key to making an informed decision. The primary drawback becomes apparent when the sample is not a solid, self-supporting object.

Handling Powders and Melts

For processing powders, materials that will melt, or any substance that cannot support its own shape, a vertical furnace is superior. Gravity keeps the material contained within a crucible at the bottom of the furnace, preventing it from spilling or touching the tube walls, which would cause damage and contamination.

Processing Large or Heavy Samples

Vertical furnaces with bottom-loading elevators are better suited for handling heavy or bulky samples. A horizontal orientation would require complex and often impractical support structures to prevent sagging at high temperatures.

When Convection is Desired

In some specific applications, the strong natural convection within a vertical furnace can be leveraged to promote gas mixing. However, for most high-precision work, this effect is a source of non-uniformity that must be minimized.

Making the Right Choice for Your Application

Ultimately, the furnace orientation must serve the needs of your material and your process.

- If your primary focus is the thermal treatment of wires, rods, thin films, or other solid, self-supporting samples: The horizontal furnace's superior axial thermal uniformity and ease of use is the definitive choice.

- If your primary focus is melting, sintering powders, or containing liquids at high temperatures: A vertical furnace is non-negotiable to manage the material safely and effectively using gravity.

- If your primary focus is lab space efficiency and simple operation for solid samples: The compact, benchtop design and straightforward loading of a horizontal furnace are ideal.

By aligning the furnace orientation with your sample's geometry and process goals, you ensure the precision and reliability of your thermal treatment.

Summary Table:

| Feature | Benefit for Small-Diameter Samples |

|---|---|

| Superior Thermal Uniformity | Ensures even heating along the sample length, reducing temperature gradients |

| Simplified Loading | Easy insertion and observation of delicate samples like wires and rods |

| Compact Design | Fits efficiently on lab benches, saving space |

| Efficient Atmosphere Control | Maintains consistent gas flow for high-purity processes |

| Direct Radiant Heat Transfer | Provides consistent and efficient heating for uniform results |

Optimize your thermal processing with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, and Rotary Furnaces, tailored to your unique needs. Whether you're working with small-diameter samples or require deep customization, our expertise ensures precise and reliable performance. Contact us today to discuss how we can enhance your lab's efficiency and achieve superior results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents