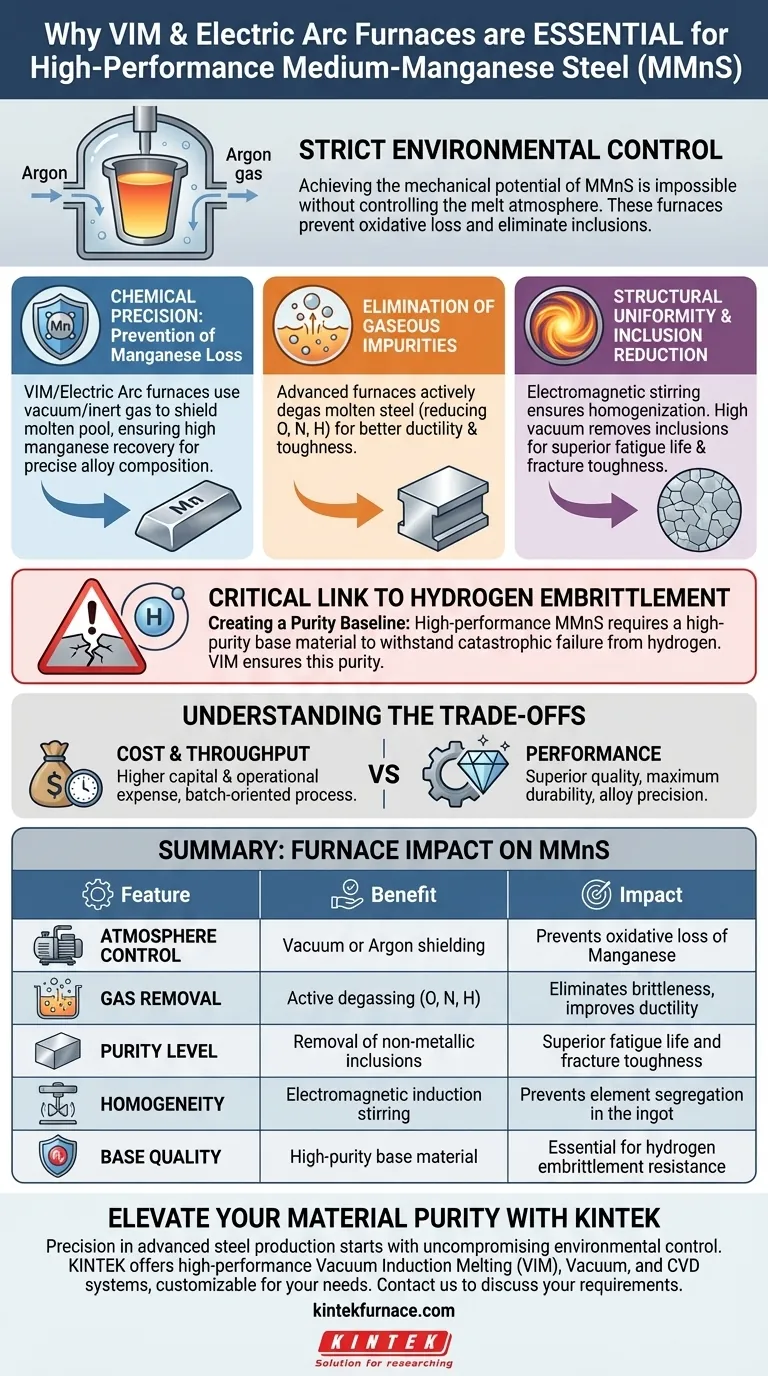

The production of high-performance Medium-Manganese Steel (MMnS) relies entirely on strict environmental control during the melting phase. Industrial-grade Vacuum Induction Melting (VIM) furnaces or electric arc furnaces are essential because they provide the precise regulation of gas content—specifically oxygen, nitrogen, and hydrogen—required to remove harmful impurities. This high-vacuum or argon-protected environment ensures the maximum recovery of manganese and creates the high-purity base material needed to resist hydrogen embrittlement.

Core Takeaway Achieving the mechanical potential of Medium-Manganese Steel is impossible without controlling the melt atmosphere. These furnaces prevent the oxidative loss of manganese and eliminate microscopic inclusions, ensuring the material is pure enough to withstand critical failure modes like hydrogen embrittlement.

The Imperative of Chemical Precision

Prevention of Manganese Loss

Manganese is a reactive element that is prone to significant oxidative loss when exposed to air at melting temperatures.

VIM and electric arc furnaces utilize vacuum or inert gas (argon) environments to shield the molten pool. This ensures a high recovery rate of manganese, maintaining the precise alloy composition required for the steel's intended mechanical properties.

Elimination of Gaseous Impurities

Standard melting processes often trap gases that degrade steel performance.

Advanced furnaces equipped with vacuum decarburization units or argon protection actively degas the molten steel. This significantly reduces the content of oxygen, nitrogen, and hydrogen, which are detrimental to the material's ductility and toughness.

Achieving Structural Uniformity

Reduction of Harmful Inclusions

Impurities in the melt eventually solidify into inclusions, which act as stress concentrators within the finished steel.

By operating in a high-vacuum environment, these furnaces facilitate the removal of these non-metallic inclusions. The result is a cleaner microstructure that exhibits superior fatigue life and fracture toughness.

Homogenization via Electromagnetic Stirring

A distinct advantage of VIM furnaces is the use of electromagnetic induction.

This mechanism naturally stirs the molten metal, ensuring a high degree of compositional homogenization. It guarantees that alloying elements like iron, manganese, and carbon are evenly distributed throughout the ingot, preventing segregation.

The Critical Link to Hydrogen Embrittlement

Creating a Purity Baseline

Hydrogen embrittlement is a catastrophic failure mode where metal becomes brittle and fractures due to the introduction of hydrogen.

High-performance MMnS requires a high-purity base material to properly evaluate and achieve resistance to this phenomenon. If the base material is already compromised by hydrogen or inclusions during melting, its resistance to environmental hydrogen embrittlement cannot be accurately assessed or guaranteed.

Understanding the Trade-offs

Cost vs. Performance

While VIM and specialized electric arc furnaces offer superior quality, they represent a significant capital and operational expense compared to standard induction melting.

Throughput Limitations

Vacuum processes are inherently batch-oriented and time-consuming due to the need for pumping down creates and backfilling with argon. This can act as a bottleneck in high-volume production environments, forcing manufacturers to balance purity requirements with production speed.

Making the Right Choice for Your Goal

When selecting a production route for Medium-Manganese Steel, consider your end-use requirements:

- If your primary focus is Maximum Durability: Prioritize VIM processing to minimize inclusions and maximize hydrogen embrittlement resistance.

- If your primary focus is Alloy Precision: Use vacuum or argon-protected environments to ensure the final manganese content matches your exact specifications without oxidative loss.

Ultimate reliability in advanced steels is not just about the recipe; it is about the purity of the kitchen.

Summary Table:

| Feature | VIM / Electric Arc Furnace Benefit | Impact on Medium-Mn Steel |

|---|---|---|

| Atmosphere Control | Vacuum or Argon shielding | Prevents oxidative loss of Manganese |

| Gas Removal | Active degassing (O, N, H) | Eliminates brittleness and improves ductility |

| Purity Level | Removal of non-metallic inclusions | Superior fatigue life and fracture toughness |

| Homogeneity | Electromagnetic induction stirring | Prevents element segregation in the ingot |

| Base Quality | High-purity base material | Essential for hydrogen embrittlement resistance |

Elevate Your Material Purity with KINTEK

Precision in advanced steel production starts with uncompromising environmental control. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum Induction Melting (VIM), Vacuum, and CVD systems, along with other specialized lab high-temp furnaces. Our systems are fully customizable to meet your unique metallurgical needs, ensuring maximum manganese recovery and the elimination of harmful impurities.

Ready to achieve the ultimate reliability in your alloy development?

Contact KINTEK Experts Today to discuss your custom furnace requirements.

Visual Guide

References

- Mahmoud Elaraby, Vahid Javaheri. Computational Designing Approach for Medium Manganese Steels with Potential Better Hydrogen Embrittlement Resistance. DOI: 10.3384/ecp212.032

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is a Vacuum Induction Melting (VIM) furnace and what does it do? Discover Precision Melting for High-Purity Alloys

- What is the critical role of a Vacuum Induction Melting furnace in FeAl alloy prep? Achieve Ultra-High Purity Alloys

- Why are hollow copper tubes used for induction furnace coils? Essential Cooling for High-Power Melting

- How do channel induction furnaces improve the working environment? Achieve a Safer, Cleaner, and Quieter Workplace

- What principle does an induction heater circuit operate on? Discover Efficient, Contactless Heating

- How does a Vacuum-arc melting furnace ensure the compositional uniformity of Ti–Mo–Fe alloy ingots? Master Homogeneity

- What essential conditions does a crucible melting furnace provide for Al-Si alloys? Master Your Casting Precision

- What is crucible in an induction furnace? The Key to Safe, Efficient Metal Melting