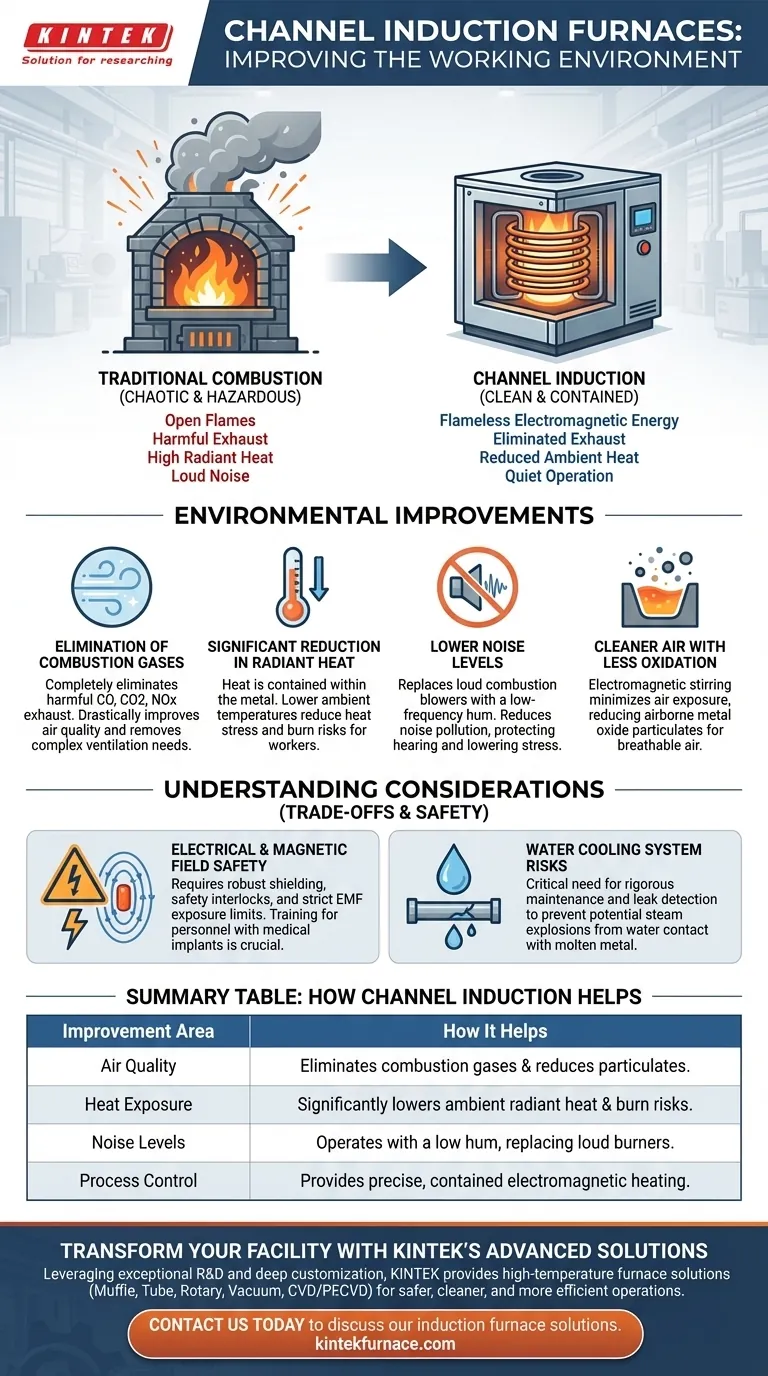

In essence, channel induction furnaces create a superior working environment by replacing the chaotic, hazardous process of combustion with clean, contained electromagnetic energy. This fundamental shift eliminates open flames and their associated byproducts, significantly reduces noise levels, and allows for precise control, resulting in a workplace that is demonstrably safer, cleaner, and healthier for operators.

The core reason for the improved working environment is the shift from fossil fuel combustion to contained electromagnetic induction. This change systematically removes the primary sources of atmospheric, acoustic, and radiant heat hazards that are inherent in traditional furnaces.

Deconstructing the Environmental Improvements

The benefits to the working environment are not a single feature but a collection of outcomes stemming directly from the furnace's core technology.

Elimination of Combustion and Exhaust Gases

Traditional furnaces burn fuel, releasing a host of harmful byproducts directly into the workplace atmosphere, including carbon monoxide (CO), carbon dioxide (CO2), and nitrogen oxides (NOx).

Channel induction furnaces use flameless electromagnetic heating. This process completely eliminates the generation of combustion-related exhaust gases, drastically improving air quality and removing the need for complex exhaust ventilation systems.

Reduction in Radiant Heat

The open flames and superheated exterior surfaces of conventional furnaces radiate intense heat, creating a physically taxing and uncomfortable environment for workers.

Because induction heating occurs within the metal itself and the process is contained, ambient temperatures around the furnace are significantly lower. This reduces the risk of heat stress and burns, creating a more tolerable workspace.

Lower Noise Levels

Combustion-based systems are notoriously loud, relying on powerful blowers, fuel pumps, and roaring burners that contribute to high-decibel industrial noise.

A channel induction furnace's primary sound is a low-frequency electrical hum, which is a dramatic reduction in noise pollution. This quieter operation helps protect worker hearing and reduces overall job-related stress.

Cleaner Air with Less Oxidation

The induction process generates a stirring effect below the surface of the molten metal, which minimizes its exposure to oxygen in the air.

This not only improves metal quality but also reduces the formation of metal oxides that can become airborne particulates. A lower concentration of these fine particles contributes to cleaner, more breathable air.

Understanding the Trade-offs and Considerations

While the benefits are significant, adopting induction technology introduces a different set of operational and safety protocols that must be managed.

Electrical and Magnetic Field Safety

Channel induction furnaces operate with extremely high levels of electric current and generate powerful magnetic fields.

Proper installation requires robust shielding, safety interlocks, and strict adherence to personnel exposure limits for electromagnetic fields (EMF). Workers, particularly those with medical implants, must be trained on safe operating distances and procedures.

Water Cooling System Risks

These furnaces rely on high-volume water cooling systems to manage the heat generated in the induction coils and power supply.

A failure or leak in this system is a critical risk. Any potential for water to come into contact with molten metal must be mitigated through rigorous preventative maintenance, leak detection sensors, and emergency protocols to prevent steam explosions.

Making the Right Choice for Your Goal

When evaluating a channel induction furnace, your specific priorities will determine which benefits are most critical to your operation.

- If your primary focus is worker health and regulatory compliance: The complete elimination of combustion gases (CO, NOx) and reduced particulate matter are your most compelling justifications.

- If your primary focus is improving safety and reducing accidents: The combination of lower radiant heat, a contained melt, and precise temperature control drastically lowers the risk of burns and splashes.

- If your primary focus is operational quality of life and employee retention: The dramatic reduction in ambient heat and noise creates a far less demanding and more desirable work environment.

Adopting channel induction technology is a strategic investment in a fundamentally safer, cleaner, and more controlled production environment.

Summary Table:

| Improvement Area | How Channel Induction Furnaces Help |

|---|---|

| Air Quality | Eliminates combustion gases (CO, NOx) and reduces metal oxide particulates. |

| Heat Exposure | Significantly lowers ambient radiant heat, reducing burn risks and heat stress. |

| Noise Levels | Operates with a low hum, replacing loud combustion blowers and burners. |

| Process Control | Provides contained, precise electromagnetic heating for a cleaner melt. |

Ready to transform your foundry or metal processing facility into a safer, cleaner, and more efficient operation?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories and industrial facilities with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique operational requirements—whether you're prioritizing worker safety, regulatory compliance, or superior process control.

Contact us today to discuss how our induction furnace solutions can create a superior working environment for your team.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What components make up a Vacuum Induction Melting Furnace? Discover the Key Systems for Pure Metal Melting

- What are the key features and benefits of a Vacuum Induction Melting Furnace? Achieve High-Purity Metal Production

- How is operator safety ensured during the vacuum induction melting process? Discover Multi-Layered Protection for Your Lab

- What industries benefit from Vacuum Induction Melting Furnaces? Unlock High-Purity Metals for Aerospace, Medical, and More

- What are the main industrial applications of vacuum melting furnaces? Achieve Unmatched Material Purity and Performance