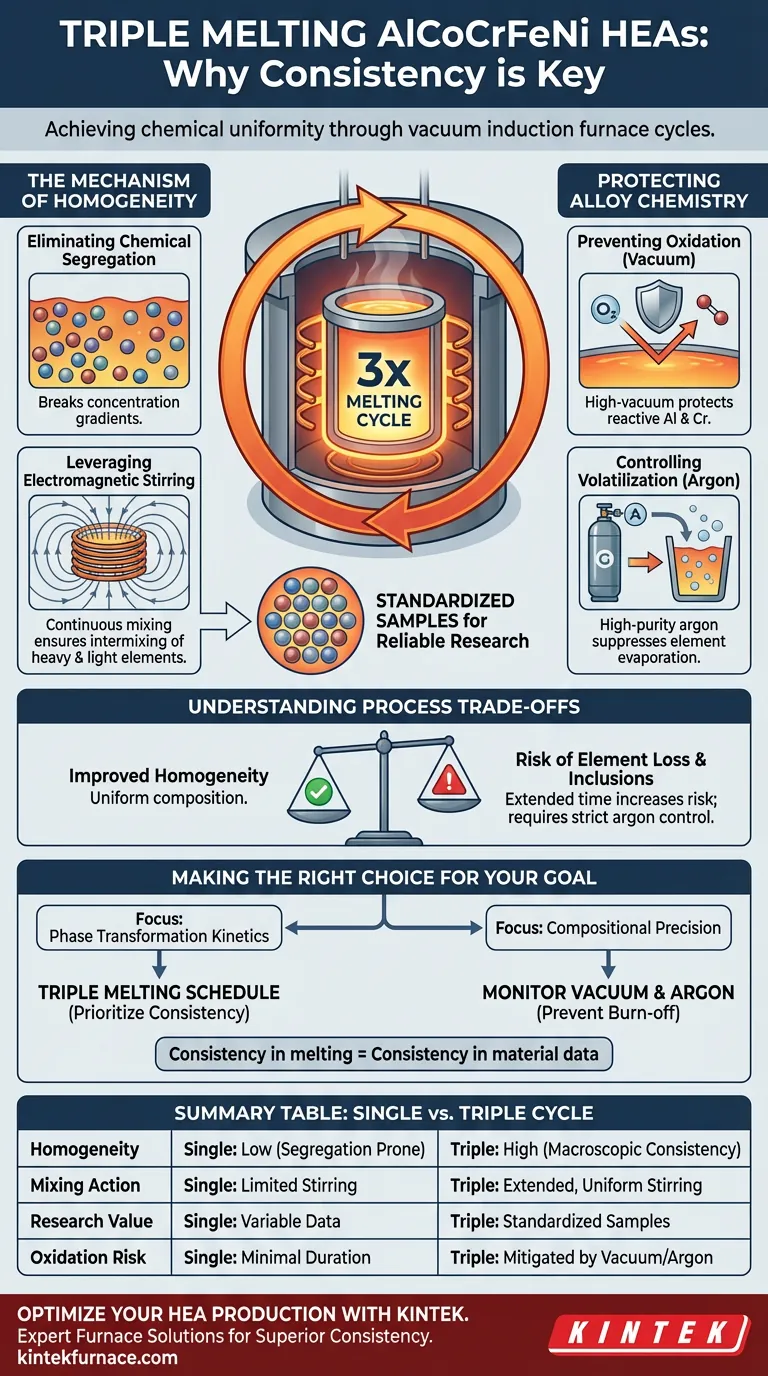

The repetition of the melting and casting process is fundamentally about achieving chemical uniformity. For complex multi-element systems like AlCoCrFeNi, a single melt is rarely sufficient to fully integrate the elements. Repeating the cycle three times utilizes continuous electromagnetic stirring to eliminate segregation, ensuring the final alloy is homogeneous.

The primary purpose of this triple-melting strategy is to leverage multiple melting-solidification cycles and electromagnetic stirring to eradicate chemical segregation within the liquid metal. This guarantees that large ingots possess high compositional consistency at both macroscopic and microscopic levels, creating standardized samples essential for accurate phase transformation research.

The Mechanism of Homogeneity

Eliminating Chemical Segregation

In high-entropy alloys, elements with different densities and melting points tend to separate, a phenomenon known as segregation. Running the melting and casting cycle three times combats this natural tendency. The repeated transitions between liquid and solid states force the redistribution of elements, breaking down concentration gradients that form during a single melt.

Leveraging Electromagnetic Stirring

The vacuum induction furnace provides more than just heat; it actively mixes the alloy. The induction field creates strong stirring forces within the molten metal. By maintaining this stirring across multiple cycles, the process ensures that heavy and light elements—such as Iron and Aluminum—are thoroughly intermixed.

Standardizing Research Baselines

The ultimate goal of this rigorous processing is to create a "standardized starting sample." Any variation in chemical composition across the ingot would skew data regarding phase transformation kinetics. Triple melting ensures that the material properties observed in later research are intrinsic to the alloy design, not artifacts of poor mixing.

Protecting the Alloy Chemistry

Preventing Oxidation of Reactive Elements

While mixing is the goal of repetition, the vacuum environment is critical for the survival of the alloy components. Elements like Aluminum (Al) and Chromium (Cr) are highly reactive and prone to oxidation. The high-vacuum environment prevents these elements from reacting with oxygen, which would form defects and weaken the material.

Controlling Volatilization

High-entropy alloys often contain elements with high vapor pressures that can "burn off" or evaporate during prolonged melting. To counter this, high-purity argon gas is introduced to maintain atmospheric pressure during the melt. This suppresses volatilization, ensuring the final alloy retains the exact equimolar proportions intended by the design.

Understanding the Process Trade-offs

Balancing Mixing vs. Element Loss

While repeated melting improves homogeneity, it also increases the total time the metal spends in a liquid state. Extended processing times increase the risk of volatile elements evaporating, potentially shifting the alloy's composition away from the design. Strict control of the argon atmosphere is required to mitigate this risk during the three cycles.

Managing Inclusion Risks

Every melting cycle presents a theoretical risk of introducing impurities or crucible contamination. However, the vacuum induction process mitigates this by using repeated argon purging to remove residual oxygen. If the purge is insufficient, oxide inclusions can form, compromising the structural integrity of the eutectic alloy.

Making the Right Choice for Your Goal

When designing a fabrication protocol for high-entropy alloys, consider your specific research objectives:

- If your primary focus is Phase Transformation Kinetics: Prioritize the triple-melting schedule to ensure absolute chemical consistency across the entire ingot.

- If your primary focus is Compositional Precision: Monitor the vacuum and argon pressure levels strictly to prevent the burn-off of high vapor pressure elements during the repeated cycles.

Consistency in the melting process is the only way to guarantee consistency in your material data.

Summary Table:

| Feature | Single Melting Cycle | Triple Melting Cycle |

|---|---|---|

| Homogeneity | Low; prone to element segregation | High; ensures macroscopic consistency |

| Mixing Action | Limited electromagnetic stirring | Extended stirring for uniform distribution |

| Research Value | Variable data due to composition | Standardized samples for phase kinetics |

| Oxidation Risk | Minimal duration exposure | Mitigated by high-vacuum/argon purging |

Optimize Your High-Entropy Alloy Production with KINTEK

Consistency in your melting process is the foundation of reliable material data. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces—all fully customizable to your unique research needs.

Whether you are refining AlCoCrFeNi compositions or developing next-generation HEAs, our precision equipment ensures superior temperature control and atmosphere stability. Contact KINTEK today to discover how our advanced furnace solutions can enhance your laboratory's efficiency and material integrity.

Visual Guide

References

- Mudassar Hussain, Tuty Asma Abu Bakar. X-Ray Diffraction Analysis of Sigma-Phase Evolution in Equimolar AlCoCrFeNi High Entropy Alloy. DOI: 10.15282/ijame.21.4.2024.14.0917

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What are the key steps in the vacuum induction melting process? Achieve High-Purity Metal Alloys for Demanding Applications

- What safety features should be looked for in an induction melting furnace? Ensure Operator and Facility Protection

- What makes IGBT technology advantageous for induction heating? Achieve Precision, Efficiency, and Speed

- Why is a diffusion pump and high-purity argon required for TiAl alloy sintering? Achieve High-Performance Results

- How are medium frequency induction furnaces used in forging and forming? Achieve Rapid, Uniform Heating for Superior Parts

- Why are independent melting furnaces and injection chambers required for cold chamber die casting machines? Explained

- What role does a medium-frequency induction furnace play in TiCp/Fe composite preparation? Expert Insights

- Why is repeated melting and flipping of alloy ingots necessary? Achieving Homogeneity in Mn–Ni–Fe–Si Alloys