The primary necessity for repeated melting and flipping is to counteract the localized heating nature of the electric arc. Because the arc applies intense heat to a specific area while the bottom of the ingot remains in contact with a cold hearth, severe temperature gradients occur. Manually flipping and remelting the ingot is the only mechanical way to ensure that all distinct elements—manganese, nickel, iron, and silicon—undergo complete mutual diffusion, resulting in a chemically homogeneous alloy.

Core Takeaway An arc melting furnace creates a concentrated heat source that can leave an alloy separated by density and melting point. By mechanically flipping and fusing the ingot multiple times, you force convective mixing to occur throughout the entire volume, eliminating macro-segregation and ensuring the final material is uniform from center to edge.

The Physics of Homogeneity

Overcoming Localized Arc Heating

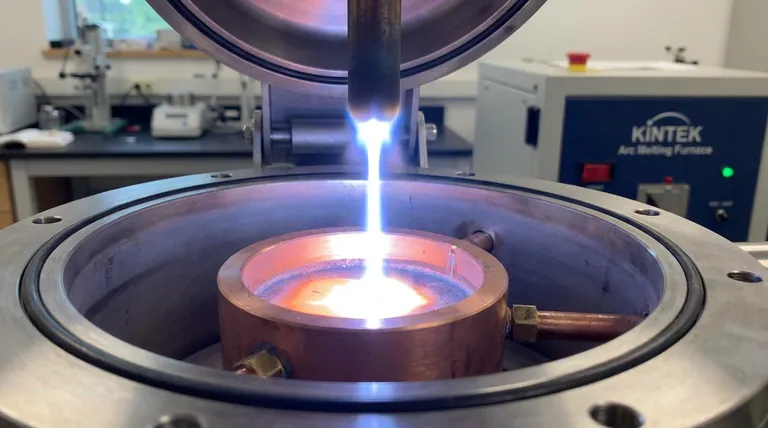

The electric arc does not heat the raw materials evenly; it creates a zone of intense, localized energy. This results in steep temperature gradients across the sample, where the top is molten and the bottom acts as a heat sink.

Without intervention, these gradients prevent the full volume of the ingot from reaching the same state of fluidity simultaneously. Flipping ensures that the cooler, bottom sections are brought to the top to be directly exposed to the arc's heat.

Ensuring Mutual Diffusion

For a complex system like Mn–Ni–Fe–Si, the elements have different melting points and densities. Simply melting them once often results in layers or pockets of elemental concentration.

Repeated fusion drives the mutual diffusion of these elements. It forces the atoms to intermingle at a fundamental level, breaking down clusters of pure material and distributing the manganese, nickel, iron, and silicon evenly throughout the matrix.

The Role of Gravity and Cooling

Utilizing Convective Forces

Achieving a uniform mix requires more than just heat; it requires movement within the liquid melt. When the ingot is flipped and remelted, the liquid alloy is subjected to convective mixing.

This mixing is driven by a combination of gravity and the electromagnetic forces of the arc itself. These forces churn the molten pool, physically moving heavier and lighter elements into a cohesive solution.

Combatting Macro-Segregation

The goal of this process is to eliminate macro-segregation, which is the gross separation of alloying elements. If the liquid is not agitated sufficiently via repeated melting, the final solid will have chemically distinct regions.

This is particularly critical because the water-cooled copper crucible used in these furnaces provides a high cooling rate. While this rapid cooling facilitates fine solidified microstructures, it creates a risk: it can "freeze" the alloy before it is fully mixed if the flipping process is neglected.

Understanding the Trade-offs

The "Cold Hearth" Effect

The very feature that protects the equipment—the water-cooled copper crucible—creates a significant thermal barrier. While it prevents the crucible from melting, it actively works against the arc by keeping the bottom of the ingot cold.

The Necessity of Repetition

There is no shortcut to overcoming this thermal disparity. A single melt, regardless of duration, is rarely sufficient to penetrate the entire depth of the ingot against the cooling power of the crucible. The trade-off for using a clean, non-reactive cold crucible is the operational requirement to manually intervene (flip) multiple times to guarantee consistency.

Making the Right Choice for Your Goal

To ensure your Mn–Ni–Fe–Si alloy meets the required specifications, apply the following principles:

- If your primary focus is Chemical Homogeneity: You must prioritize the number of flip-and-remelt cycles over the duration of a single melt to ensure complete mutual diffusion.

- If your primary focus is Microstructure Refinement: Rely on the high cooling rate of the water-cooled crucible, but only after you have confirmed the absence of macro-segregation through repeated melting.

Uniformity in arc melting is not an automatic result of high heat; it is the deliberate outcome of mechanical persistence.

Summary Table:

| Challenge | Impact on Alloy | Solution Strategy |

|---|---|---|

| Localized Arc Heating | Intense temperature gradients; bottom stays cold | Flip ingot to expose the bottom to direct arc heat |

| Elemental Segregation | Non-uniform density & melting point distribution | Drive mutual diffusion through repeated fusion cycles |

| Cold Hearth Effect | Rapid solidification before complete mixing | Mechanical intervention to force convective mixing |

| Macro-segregation | Chemically distinct regions in the final solid | Prioritize cycle count over single melt duration |

Optimize Your Alloy Production with KINTEK

Don't let macro-segregation compromise your material integrity. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Arc Melting, Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique laboratory and production needs.

Whether you are refining complex Mn–Ni–Fe–Si systems or developing next-generation materials, our high-temperature solutions provide the precision control required for perfect homogeneity.

Ready to elevate your research? Contact our technical experts today to find the ideal furnace configuration for your application.

References

- Shantanu Kumar Panda, Manoranjan Kar. Effect of temperature and magnetic field induced hysteresis on reversibility of magnetocaloric effect and its minimization by optimizing the geometrical compatibility condition in Mn–Ni–Fe–Si alloy. DOI: 10.1063/5.0177061

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Magnesium Extraction and Purification Condensing Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the advantages and uses of induction furnaces in foundries? Achieve Fast, Clean, and Precise Metal Melting

- Why is multiple remelting necessary in vacuum arc melting? Ensure alloy homogeneity and structural integrity.

- How are induction furnaces used in investment casting? Achieve Precision Melting for High-Quality Cast Parts

- How does the controlled cooling environment of a melting furnace affect the microstructure of CoCuMoNiAl alloy ingots?

- What safety advantages do induction gold melting furnaces offer? Flameless, Contained Melting for Maximum Operator Safety

- How does an induction furnace heat metal? Achieve Fast, Clean, and Precise Metal Melting

- What are the main benefits of an induction vacuum melting furnace? Achieve High-Purity Metals for Demanding Industries

- What role does sustainability play in the IGBT induction melting furnace market? A Key Driver for Modern Foundries