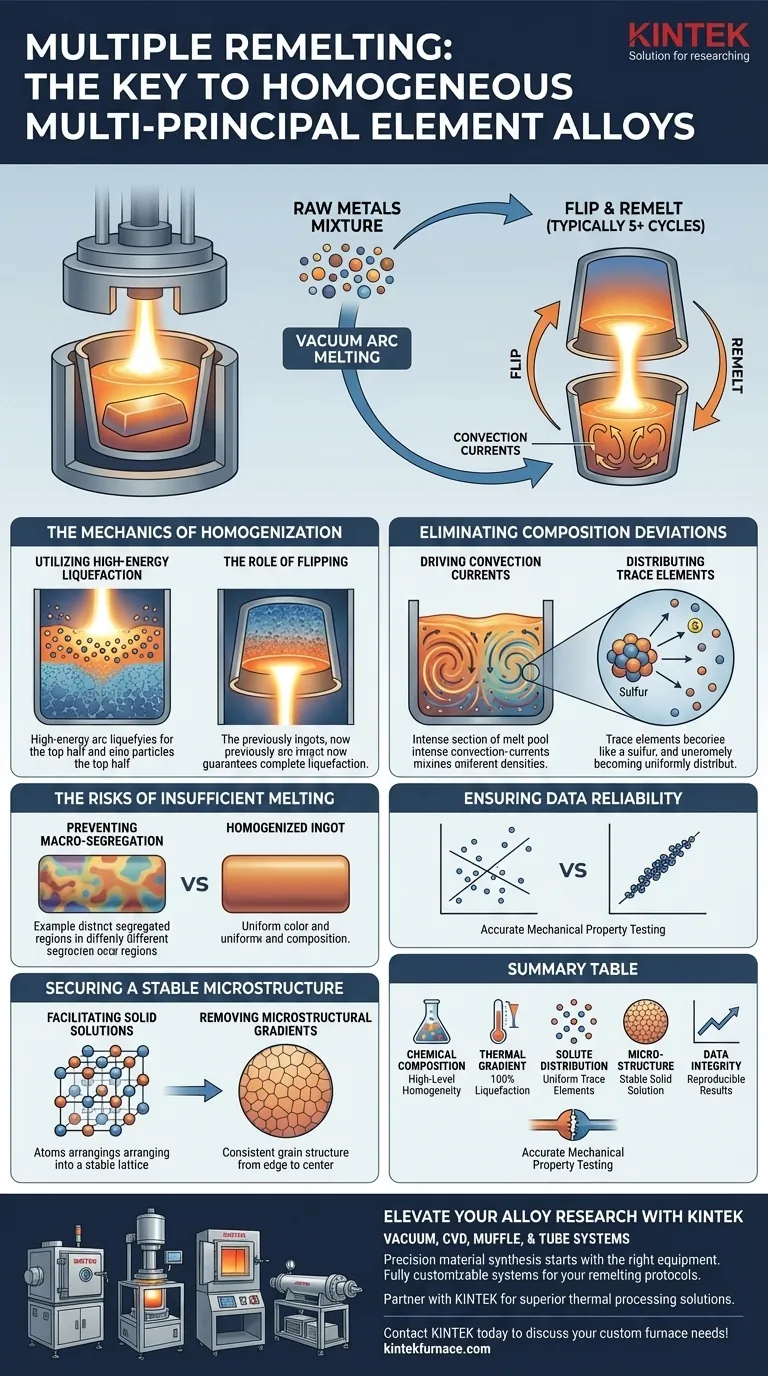

Multiple remelting is a non-negotiable requirement in vacuum arc melting to transform a mixture of raw metals into a consistent, high-quality alloy. By flipping the sample and remelting it typically at least five times, you ensure that every distinct metal particle is fully liquefied and that the chemical composition becomes uniform throughout the entire ingot.

In the production of multi-principal element alloys, a single melt is almost never sufficient to create a stable material. The repetitive process of flipping and remelting utilizes melt pool convection to eliminate composition gradients, ensuring the final alloy is chemically homogeneous and structurally sound.

The Mechanics of Homogenization

Utilizing High-Energy Liquefaction

The primary goal of the vacuum arc is to deliver high energy to liquefy metal particles. However, because the bottom of the sample sits on a cooled hearth, it often remains cooler than the top.

The Role of Flipping

Flipping the ingot physically inverts the thermal gradient. This ensures that material previously at the bottom is exposed directly to the high-energy arc in the next cycle. This guarantees that all metal particles are completely liquefied, preventing unmelted raw materials from contaminating the final structure.

Eliminating Compositional Deviations

Driving Convection Currents

Chemical uniformity does not happen instantly. Each melting cycle generates convection currents within the melt pool, which acts as a stirring mechanism. Repeatedly triggering these currents is necessary to thoroughly mix elements with different densities and melting points.

Distributing Trace Elements

This mixing is particularly critical for trace elements, such as 0.2 at% sulfur or other minor solutes. Without multiple remelting cycles, these elements tend to cluster. The process creates a uniform distribution of solutes, preventing localized concentrations that could weaken the material.

The Risks of Insufficient Melting

Preventing Macro-Segregation

If the number of melting cycles is insufficient, the alloy is prone to macro-segregation. This occurs when chemical components separate into distinct regions rather than forming a cohesive whole.

Ensuring Data Reliability

Segregation is a major liability for research and development. If an ingot suffers from macro-segregation, subsequent mechanical property testing will yield inaccurate or scattershot results. Homogenization is essential to ensure that your test data actually represents the intrinsic properties of the alloy, rather than a casting defect.

Securing a Stable Microstructure

Facilitating Solid Solutions

Multi-principal element alloys rely on complex interactions between atoms to form specific phases. The repeated thermal cycling helps facilitate the formation of stable solid solution structures.

Removing Microstructural Gradients

By eliminating chemical gradients, you inevitably eliminate microstructural gradients. This results in a material where the grain structure and phase distribution are consistent from the edge of the ingot to the center.

Ensuring Process Integrity

If your primary focus is Material Stability:

Run at least five remelting cycles to ensure the formation of a stable solid solution structure free of unmelted particles.

If your primary focus is Data Accuracy:

Prioritize thorough homogenization to eliminate macro-segregation, ensuring that your mechanical testing yields reproducible and valid results.

The integrity of your final alloy is directly proportional to the rigor of your remelting process; it is the bridge between a simple mixture of metals and a sophisticated engineering material.

Summary Table:

| Aspect | Effect of Multiple Remelting | Benefit for Alloys |

|---|---|---|

| Chemical Composition | Eliminates composition gradients via convection | Achieves high-level chemical homogeneity |

| Thermal Gradient | Flipping inverts the thermal profile | Ensures 100% liquefaction of all raw materials |

| Solute Distribution | Prevents clustering of trace elements | Uniform distribution of minor solutes |

| Microstructure | Removes phase and grain gradients | Creates a stable, consistent solid solution structure |

| Data Integrity | Eliminates macro-segregation | Ensures reproducible and accurate mechanical testing |

Elevate Your Alloy Research with KINTEK

Precision in material synthesis starts with the right equipment. KINTEK provides industry-leading high-temperature lab furnaces, including Vacuum, CVD, Muffle, and Tube systems, designed to handle the rigorous demands of multi-principal element alloy production.

Backed by expert R&D and precision manufacturing, our systems are fully customizable to support your specific remelting protocols and homogenization requirements. Don't let macro-segregation compromise your research data—partner with KINTEK for superior thermal processing solutions.

Contact KINTEK today to discuss your custom furnace needs!

Visual Guide

References

- Shimaa El‐Hadad, M. M. Rashad. Magnetic Properties of Al25Co(25-x)CrxFe25-yNi25Ndy Compositionally Complex Alloys. DOI: 10.1007/s11661-025-07818-0

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- How does precise temperature control in induction furnaces benefit gold melting? Maximize Purity & Minimize Loss

- Why is a vacuum electric arc furnace essential for Ti-Al alloys? Achieve Superior Metal Purity & Homogeneity

- Why is repeated melting necessary for AlCoCrFeNi2.1 HEA? Achieving Chemical Uniformity in High-Entropy Alloys

- Why is maintaining a low-pressure vacuum environment necessary during induction heating graphitization?

- Why is the yield of inductive heating evaporation significantly higher than that of resistive heating? Maximize Your Evaporation Rate

- What are the advantages of using an induction melting furnace? Faster Melting, Lower Costs, Higher Purity

- What are five main applications of induction furnaces? Unlock Precision Melting for High-Value Metals