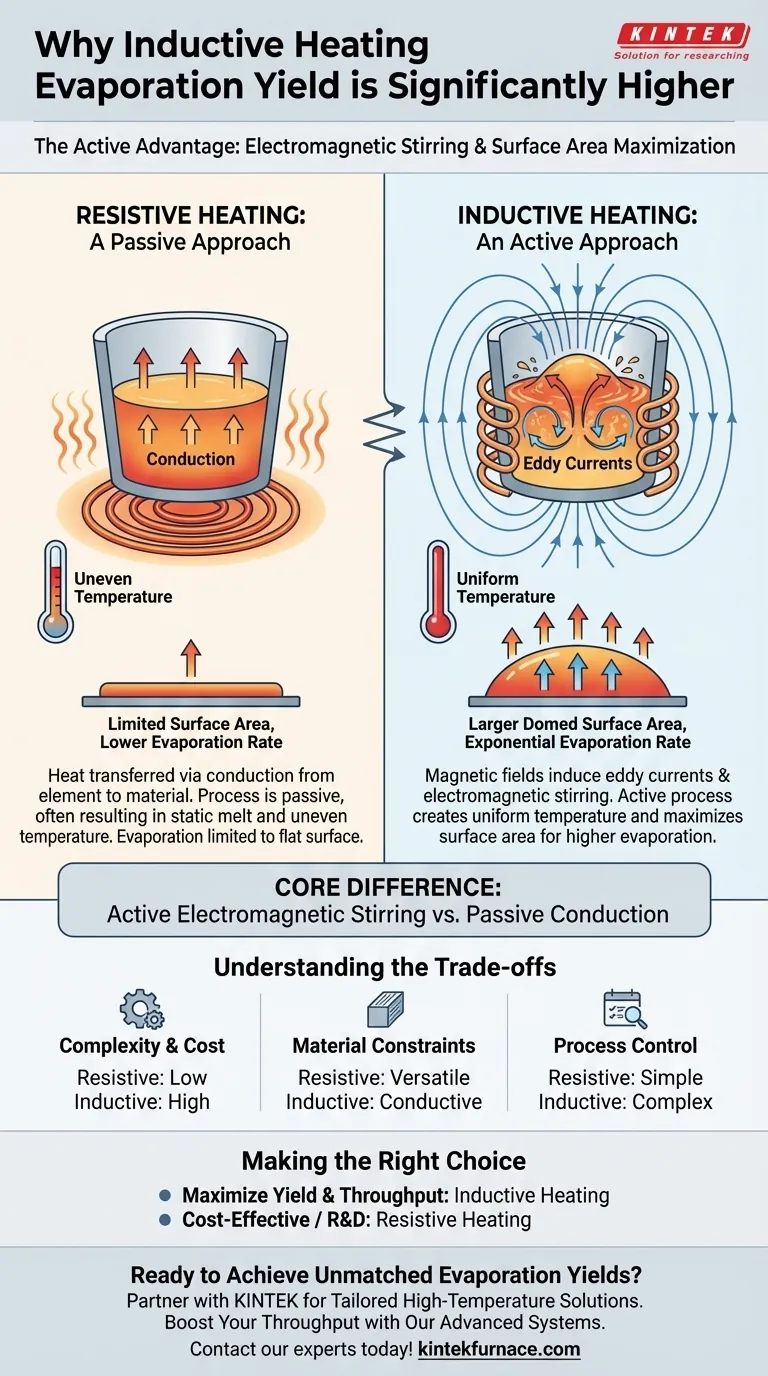

In short, the yield of inductive heating is dramatically higher because it doesn't just heat the material—it actively stirs it. This electromagnetic stirring effect creates a larger, dome-shaped surface area for evaporation and ensures the entire molten pool is at a uniform temperature, maximizing the evaporation rate in a way that passive resistive heating cannot.

The core difference isn't the amount of heat, but its application. Resistive heating is a passive process limited by conduction and a flat surface, while inductive heating is an active process that uses magnetism to increase surface area and homogenize temperature, leading to an exponential increase in yield.

The Mechanism of Resistive Heating: A Passive Approach

Resistive heating is a straightforward and common method, but its mechanics create inherent limitations for high-yield evaporation.

How It Works

Heating is achieved by passing an electrical current through a resistive element, like a crucible or boat. This element gets hot and transfers its heat to the target material primarily through conduction.

The Key Limitation: Static Heat Transfer

The process is passive. Heat slowly conducts from the container into the material. This often results in an uneven temperature distribution, with the material at the bottom being hotter than the material at the surface.

The Impact on Evaporation

Evaporation can only occur from the top surface of the molten material, which remains flat and static. Because the heat is uneven and the surface area is fixed, the overall rate of evaporation is severely limited.

The Superiority of Inductive Heating: An Active Approach

Inductive heating overcomes the limitations of resistive methods by fundamentally changing how energy is delivered to the material.

How It Works

An alternating magnetic field is generated by an induction coil. This field induces powerful electrical currents, known as eddy currents, directly within the conductive material itself. The material's own electrical resistance to these currents generates intense, uniform heat from the inside out.

The "Stirring Effect" Explained

The same magnetic fields that induce heat also exert a physical force (a Lorentz force) on the molten metal. This force creates a powerful and continuous stirring or agitation within the melt.

Maximizing Surface Area

This constant stirring action forces the liquid metal to form a semi-spherical or domed surface. This seemingly small change dramatically increases the total effective surface area from which evaporation can occur compared to a flat surface.

The Benefit of Uniform Temperature

The electromagnetic stirring ensures the entire volume of molten material is constantly mixed. This eliminates hot and cold spots, maintaining a consistent and optimal temperature throughout the melt and across the entire enlarged surface, which maximizes the evaporation rate.

Understanding the Trade-offs

While inductive heating offers a massive yield advantage for evaporation, it's essential to understand its trade-offs.

Complexity and Cost

Inductive heating systems, with their power supplies and custom-designed coils, are significantly more complex and carry a higher initial cost than simple resistive heating setups.

Material Constraints

Inductive heating works by inducing currents within the material itself. Therefore, it is most effective for electrically conductive materials. Resistive heating is more versatile, as it can heat a non-conductive crucible which then heats any material inside.

Process Control

Controlling the precise temperature and the intensity of the stirring effect in an induction system requires more sophisticated control systems compared to simply managing the power sent to a resistive element.

Making the Right Choice for Your Goal

Selecting the correct heating method depends entirely on your process priorities: efficiency, cost, or material compatibility.

- If your primary focus is maximizing yield and throughput: Inductive heating is the definitive choice. Its ability to increase surface area and ensure uniform heating delivers an unparalleled evaporation rate.

- If your primary focus is cost-effectiveness for R&D or small batches: Resistive heating provides a simpler, lower-cost, and more straightforward solution, even with its inherent efficiency limitations.

- If your primary focus is material versatility, including non-conductors: Resistive heating is often the only practical option, as it does not depend on the electrical properties of the material being evaporated.

Ultimately, your choice is dictated by whether your goal demands maximum output or prioritizes simplicity and lower capital investment.

Summary Table:

| Feature | Resistive Heating | Inductive Heating |

|---|---|---|

| Heating Mechanism | Passive conduction from a hot element | Active internal heating via eddy currents |

| Molten Pool Agitation | None (static) | High (electromagnetic stirring) |

| Evaporation Surface | Flat, limited area | Domed, significantly larger area |

| Temperature Uniformity | Often uneven | Highly uniform throughout the melt |

| Primary Advantage | Simplicity, cost-effectiveness, material versatility | Maximum evaporation yield and throughput |

Ready to Achieve Unmatched Evaporation Yields?

Your research or production process deserves the superior efficiency of inductive heating. The electromagnetic stirring effect is the key to maximizing your evaporation rate, and KINTEK's expertise makes it accessible.

Why Partner with KINTEK?

- Tailored High-Temperature Solutions: Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, including advanced inductive heating furnaces, all customizable for your unique needs.

- Boost Your Throughput: Overcome the limitations of resistive heating and achieve exponential gains in yield and process speed.

- Expert Guidance: Our team will help you select or design the perfect system to meet your specific material and output goals.

Maximize your lab's efficiency and output. Contact our experts today to discuss how our inductive heating technology can transform your evaporation processes.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

People Also Ask

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What gases are used in the PECVD system? Optimize Thin Film Deposition with Precise Gas Selection

- What are the main components of a PECVD system? Unlock Low-Temperature Thin Film Deposition

- What is the second benefit of deposition within a discharge in PECVD? Enhance Film Quality with Ion Bombardment