The primary advantages of an induction melting furnace are its exceptional speed, energy efficiency, and ability to produce higher-purity metal compared to traditional methods. These benefits stem from its unique heating method, which uses electromagnetic induction to generate heat directly within the metal charge. This leads to significant operational improvements, cost savings, and a safer work environment.

An induction furnace isn't just a faster or more efficient heater; it represents a fundamental shift in process control. By using electromagnetism to heat and stir the metal directly, it provides a level of precision, safety, and purity that traditional fuel-fired furnaces cannot match.

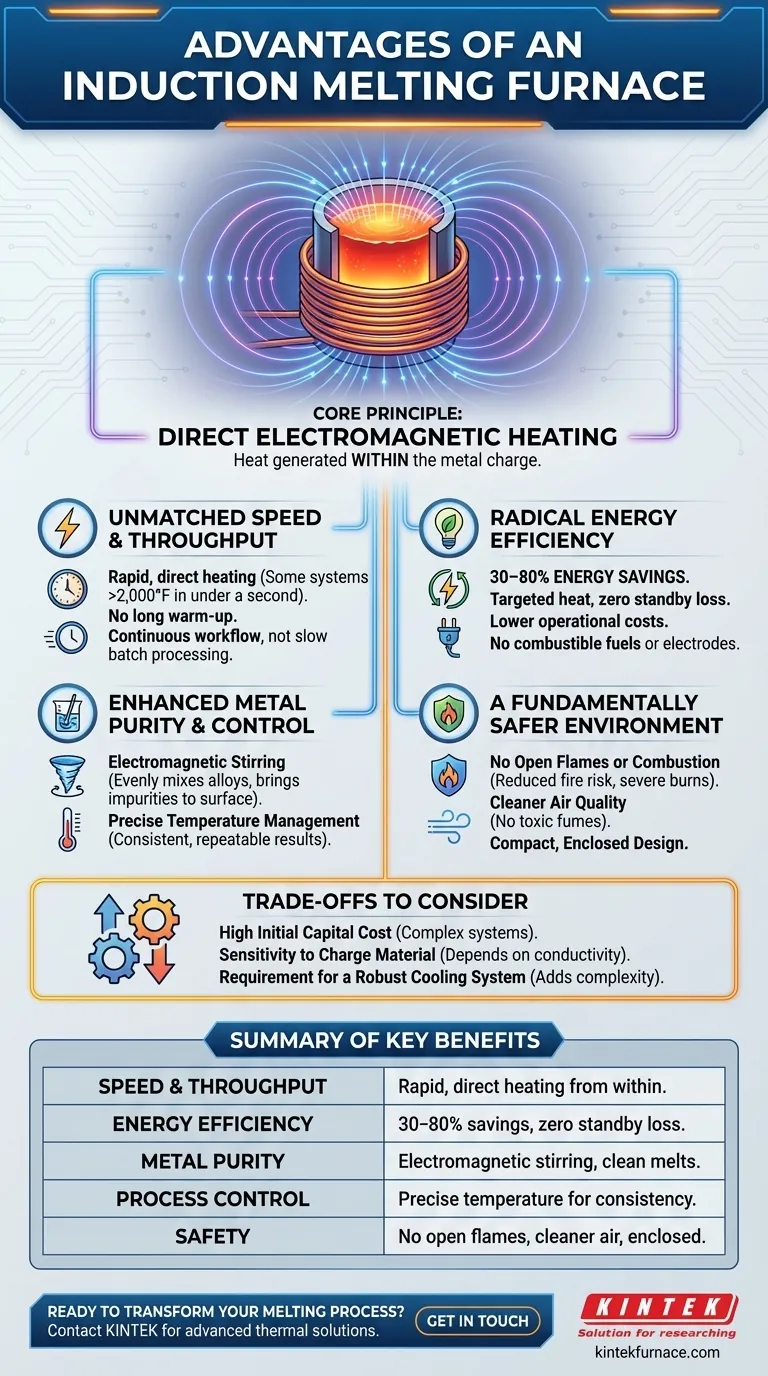

The Core Principle: How Induction Delivers Superior Performance

The key to the induction furnace's advantages lies in its method. Instead of burning fuel to heat a chamber, it uses a powerful, alternating magnetic field. This field induces electrical currents directly inside the conductive metal, causing it to heat up rapidly from within.

Unmatched Speed and Throughput

Because the heat is generated inside the metal itself, the process is incredibly fast. Some systems can heat materials to over 2,000°F in under a second.

This direct heating eliminates the long warm-up and cool-down cycles associated with traditional furnaces. A constant power output ensures the fastest possible melting speed, allowing for a continuous workflow rather than slow batch processing.

Radical Energy Efficiency

Traditional furnaces waste enormous amounts of energy heating the furnace walls and surrounding air. Induction heating is far more targeted.

With zero standby heat loss and optimized frequency control, induction furnaces can achieve energy savings of 30–80% compared to older methods. This translates directly to lower operational costs.

Eliminating Consumables and Fuel

Induction furnaces operate on electricity alone. They do not require combustible fuels, gas lines, or consumable electrodes.

This design choice lowers daily operational costs and completely eliminates the risks associated with storing and handling fuel on the work floor.

Achieving Higher Quality and Process Control

Speed and efficiency are only part of the story. The electromagnetic nature of induction melting also provides significant metallurgical advantages.

Enhanced Metal Purity

The magnetic field creates a natural stirring action within the molten metal. This electromagnetic stirring ensures alloys are mixed evenly and homogenously.

This stirring also helps bring impurities and slag to the surface, where they can be easily removed. The process occurs in a sealed environment, preventing contamination from the byproducts of combustion that are present in fuel-fired furnaces.

Precision Temperature Management

The furnace's power, and therefore the heat, can be controlled with incredible precision by adjusting the frequency and power of the electromagnetic field.

This gives operators exact control over the melting process, which is critical for meeting the strict specifications of high-performance alloys and ensuring consistent, repeatable results every cycle.

Understanding the Trade-offs

While highly advantageous, no technology is without its considerations. A complete picture requires acknowledging the practical realities.

High Initial Capital Cost

An induction furnace system represents a significant upfront investment. The power supplies, water-cooling systems, and controls are more complex and costly than a simple fuel-fired furnace.

Sensitivity to Charge Material

The efficiency of an induction furnace depends on the electrical conductivity of the material being melted. The process is less effective for materials with poor conductivity.

Furthermore, the cleanliness of the scrap metal being charged is important, as contaminants can affect the final melt chemistry and the life of the furnace lining.

Requirement for a Cooling System

The high-power induction coils generate immense heat and must be protected by a robust water-cooling system. This system adds complexity to the installation and represents another necessary point of maintenance and potential failure.

A Fundamentally Safer Working Environment

Perhaps the most compelling advantage of induction technology is the dramatic improvement in workplace safety.

No Open Flames or Combustion

The heat is entirely contained within the crucible. There are no open flames, explosive fuels, or hot exhaust gases. This single factor drastically reduces the risk of fires and severe burns.

Cleaner Air Quality

By eliminating combustion, induction furnaces produce none of the associated toxic fumes, such as carbon monoxide. This creates a much cleaner and healthier breathing environment for operators on the foundry floor.

Compact, Enclosed Design

Induction furnaces are typically more compact than traditional furnaces with equivalent output. Their enclosed design contains the process, allowing them to be placed directly on the work floor without extensive safety perimeters.

Making the Right Choice for Your Operation

Deciding to invest in an induction furnace depends entirely on your operational priorities.

- If your primary focus is maximizing output and speed: The rapid heating cycles and elimination of batch processing delays make induction the clear choice for high-throughput foundries.

- If your primary focus is reducing operational costs: The significant long-term energy savings and elimination of fuel and electrode costs provide a strong financial incentive.

- If your primary focus is producing high-purity or specialty alloys: The precise temperature control and inherent stirring action of an induction furnace offer unmatched metallurgical quality.

- If your primary focus is improving workplace safety: The enclosed, flameless operation dramatically reduces risks of fire, burns, and fume exposure, creating a modern and safe environment.

Ultimately, adopting an induction furnace is an investment in a more controlled, efficient, and safer melting process.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Speed & Throughput | Rapid, direct heating from within the metal charge |

| Energy Efficiency | 30-80% energy savings with zero standby heat loss |

| Metal Purity | Electromagnetic stirring ensures homogeneous, clean melts |

| Process Control | Precise temperature management for consistent results |

| Safety | No open flames, cleaner air, and an enclosed design |

Ready to transform your melting process with the precision and efficiency of an induction furnace?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced thermal solutions. Our high-temperature furnace expertise, including deep customization capabilities, ensures we can meet your unique operational requirements for melting, heat treatment, and more.

Contact us today to discuss how our solutions can deliver faster throughput, lower operational costs, and higher purity for your foundry or lab.

Get in touch via our Contact Form for a personalized consultation.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity