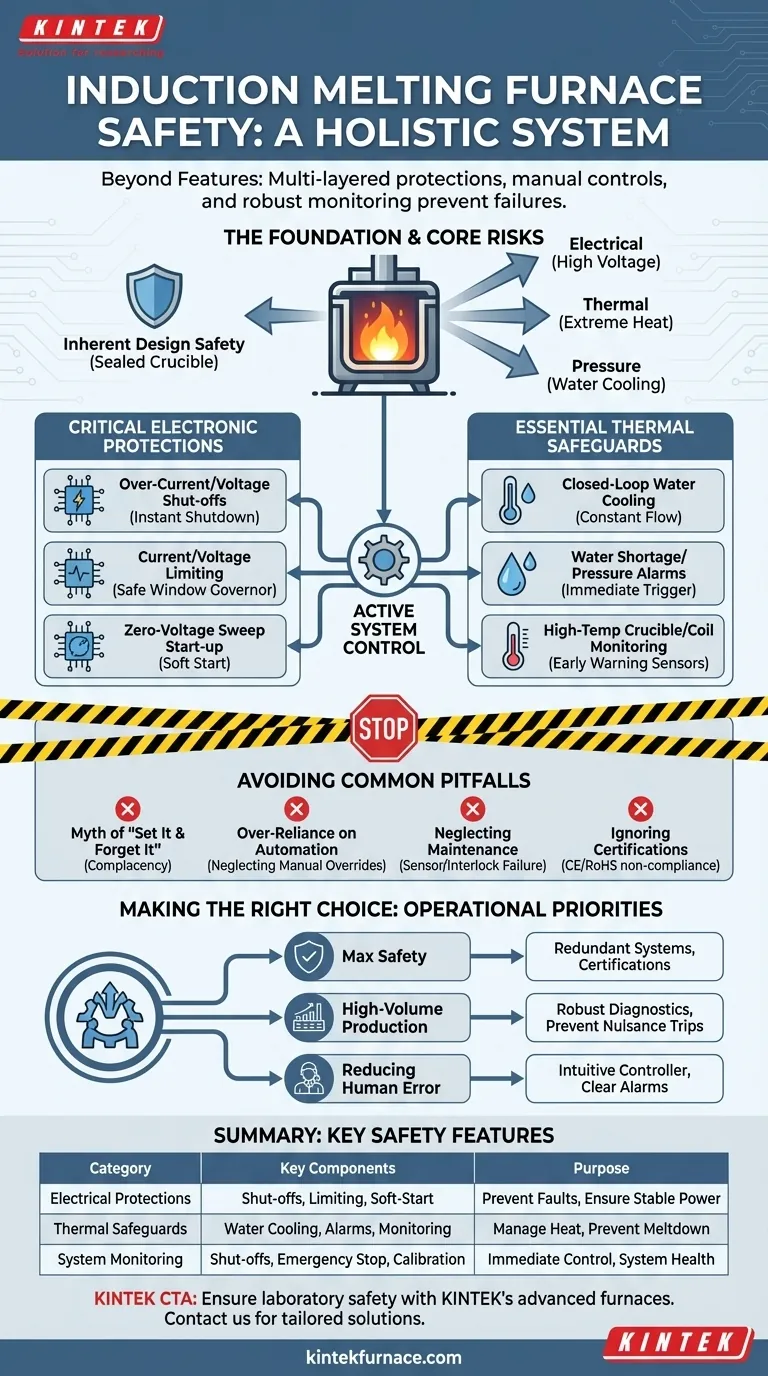

When evaluating an induction furnace, safety should be your primary consideration, treated as a complete system rather than a list of features. The most critical safety features are a multi-layered system of automatic protections, manual emergency controls, and robust system monitoring. This includes automatic shut-offs for electrical and thermal faults, prominent emergency stop buttons, and comprehensive monitoring of the water cooling and power supply systems.

True furnace safety is not found in a single feature, but in a holistic system designed to prevent failures before they happen and provide immediate control if they do. This system integrates inherent design safety, active electronic monitoring, and direct operator controls.

The Foundation of Induction Furnace Safety

To understand the necessary safety features, you must first understand the core principles and inherent risks of the technology. An induction furnace is fundamentally safer than a flame-based one, but its high-power electrical and thermal systems demand respect.

Inherent Design Safety

Induction furnaces operate without open flames or combustion byproducts. The heating process occurs within a sealed crucible, which significantly reduces the risk of fires, burns, and exposure to toxic fumes compared to traditional methods.

This enclosed design is the first layer of safety, but it does not eliminate all hazards.

The Core Risks: Electrical, Thermal, and Pressure

The primary risks stem from the core components. A high-frequency alternating current is passed through water-cooled copper coils, generating an intense magnetic field.

This creates three potential points of failure:

- Electrical: High voltage and current from the power supply.

- Thermal: Extreme heat generated within the crucible and coil.

- Pressure: The closed-loop water cooling system is under pressure and is critical for preventing catastrophic overheating.

Effective safety systems are designed to monitor and control these three areas constantly.

Critical Electronic and Electrical Protections

The furnace's power supply is its heart, and modern systems have multiple self-protection functions built directly into the control logic. These are not optional; they are essential for protecting both the equipment and the operator.

Over-Current and Over-Voltage Protection

The system must continuously monitor the electrical current and voltage being supplied to the induction coil. If it detects a spike that exceeds safe operational limits—often due to a short circuit or power grid fluctuation—it should instantly shut down power to prevent damage to the coil and power electronics.

Current-Limiting and Voltage-Limiting Functions

Separate from outright shut-offs, these functions act as governors. They ensure the furnace operates within a prescribed safe electrical window, preventing gradual damage and maintaining stable performance without tripping the main protections unnecessarily.

Zero-Voltage Sweep Start-up

A quality furnace uses software to ensure the power supply is started at zero voltage. This "soft start" prevents a sudden inrush of current, which reduces electrical stress on components and makes the frequent start-ups common in casting operations much safer and more reliable.

Essential Thermal and Mechanical Safeguards

While the electronics manage the power, a separate set of systems must manage the immense heat and the components containing it.

Closed-Loop Water Cooling System

This is arguably the most critical safety system. The copper induction coils would melt in seconds without a constant flow of cool water. A robust, closed-loop system is non-negotiable.

Water Shortage and Pressure Alarms

The cooling system must be equipped with sensors that trigger an immediate alarm and automatic furnace shutdown if water pressure drops or flow is interrupted. This is the primary defense against coil meltdown.

High-Temperature Crucible and Coil Monitoring

Modern systems use thermal sensors to monitor the temperature of the crucible and the induction coil itself. This provides an early warning if a melt is becoming too hot or if the cooling system is underperforming, allowing for corrective action before a failure occurs.

Understanding the Trade-offs and Common Pitfalls

A feature-rich furnace does not guarantee safety. Awareness of common operational assumptions and pitfalls is crucial.

The Myth of "Set It and Forget It"

Advanced automation and self-protection functions can lead to complacency. Operators must understand that these are safeguards, not substitutes for proper supervision and adherence to standard operating procedures.

Over-Reliance on Automation

While "one-button operation" simplifies processes and reduces the chance of certain errors, operators must still be trained to recognize warning signs and know how to use manual overrides, especially the emergency stop.

Neglecting Maintenance and Calibration

Safety sensors and interlocks are only effective if they are working correctly. A furnace that is not on a regular maintenance schedule for its cooling system, electrical contacts, and sensor calibration is an unquantifiable risk.

Ignoring Third-Party Certifications

Look for compliance with recognized industry standards like CE (for Europe) or RoHS. These certifications are not just paperwork; they indicate that a third party has verified the furnace's design and construction against established safety and environmental benchmarks.

Making the Right Choice for Your Operation

The ideal safety configuration depends on your specific application and operational priorities.

- If your primary focus is maximum operator and facility safety: Prioritize furnaces with redundant safety systems, comprehensive alarm logs, and internationally recognized safety certifications.

- If your primary focus is high-volume, continuous production: Emphasize robust, self-diagnostic cooling systems and advanced electronic protections that prevent nuisance trips and protect equipment from damage.

- If your primary focus is reducing human error: Look for a system with a highly intuitive smart controller, simplified operational steps, and clear, unambiguous alarm indicators.

By prioritizing a holistic safety system, you invest not just in equipment, but in the long-term resilience and security of your entire operation.

Summary Table:

| Safety Feature Category | Key Components | Purpose |

|---|---|---|

| Electrical Protections | Over-current/voltage shut-offs, current/voltage limiting, zero-voltage sweep start-up | Prevent electrical faults, ensure stable power supply |

| Thermal and Mechanical Safeguards | Closed-loop water cooling, water shortage/pressure alarms, high-temperature monitoring | Manage heat, prevent coil meltdown, and avoid overheating |

| System Monitoring and Controls | Automatic shut-offs, emergency stop buttons, sensor calibration | Provide immediate control, monitor system health, and ensure reliability |

| Certifications and Standards | CE, RoHS compliance | Verify design safety and environmental standards through third-party validation |

Ensure your laboratory's safety and efficiency with KINTEK's advanced induction melting furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable high-temperature solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Don't compromise on safety—contact us today to discuss how our tailored furnace solutions can enhance your operation's resilience and performance!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification