In short, regular calibration is essential because it ensures the temperature you set on your dental furnace is the actual temperature inside the firing chamber. This process directly guarantees the predictability, structural integrity, and aesthetic quality of your restorations. It should be managed through a consistent schedule of professional servicing and routine in-house checks.

An uncalibrated furnace introduces an unacceptable variable into a precision process. Calibration is not just about maintenance; it is a fundamental quality control step that transforms your furnace from a potential source of error into a reliable and predictable instrument.

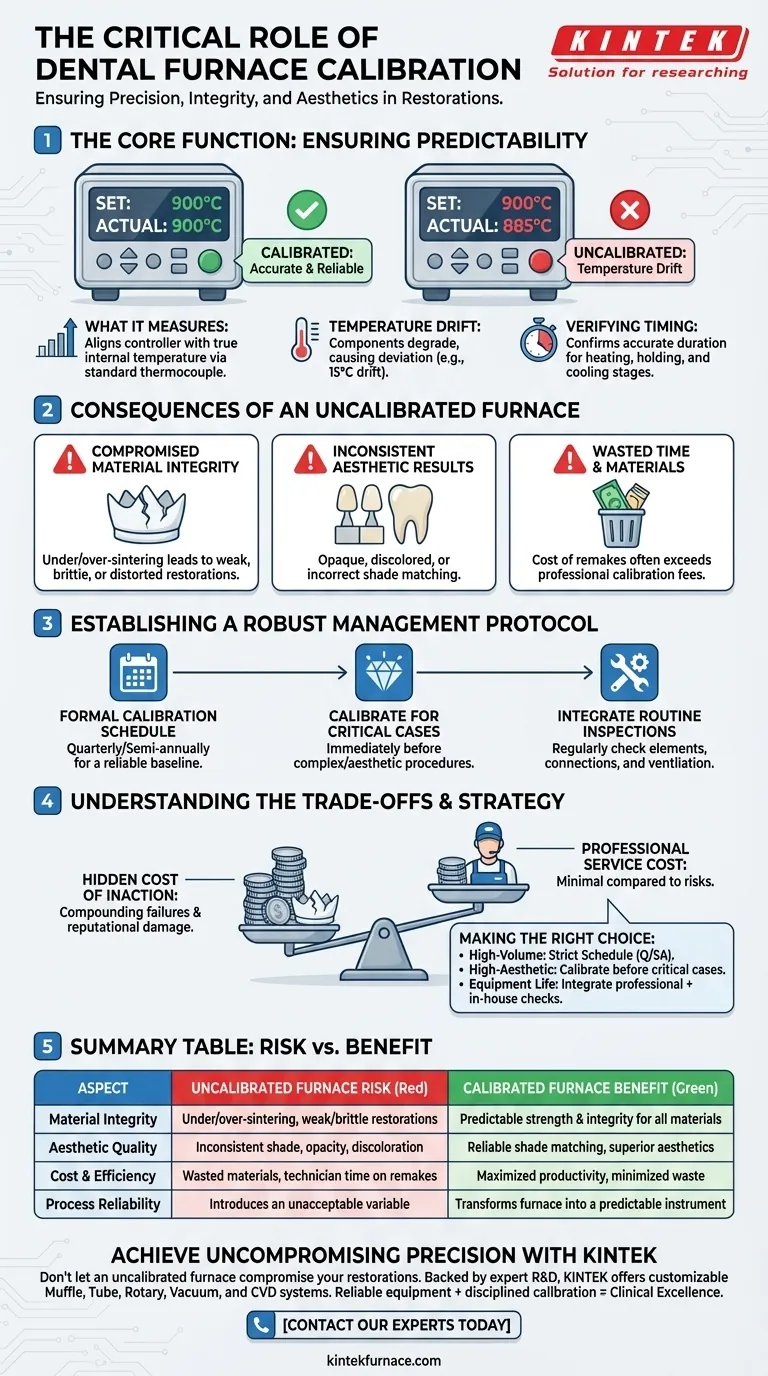

The Core Function of Calibration: Ensuring Predictability

A dental furnace is a precision instrument designed to execute specific heating protocols. Calibration is the process that verifies its accuracy.

What Calibration Actually Measures

Calibration aligns the furnace's temperature controller and display with the true temperature inside the muffle. This is typically done by a qualified technician using a standardized, independent thermocouple to measure the heat and adjust the furnace's internal settings to match.

The Problem of "Temperature Drift"

Over time, components like heating elements and thermocouples degrade. This causes "drift," where the furnace might display 900°C but only be reaching 885°C, or vice versa. This seemingly small deviation is enough to compromise the final restoration.

Beyond Temperature: Verifying Timing

Proper calibration also confirms that the furnace's timing for each stage of the sintering cycle—from heating and holding to cooling—is accurate. Incorrect timing can be just as detrimental as incorrect temperature.

The Consequences of an Uncalibrated Furnace

Failing to calibrate your furnace has direct, tangible consequences that impact your work, your materials, and your lab's reputation.

Compromised Material Integrity

Modern dental materials like zirconia and lithium disilicate have very specific sintering parameters. An uncalibrated furnace can lead to under-sintering, resulting in a porous and weak restoration, or over-sintering, which can cause brittleness, shrinkage, and distortion.

Inconsistent Aesthetic Results

Temperature accuracy is critical for achieving the desired shade and translucency. Even minor deviations can lead to restorations that are opaque, discolored, or do not match the shade guide, forcing a costly remake.

Wasted Time and Materials

Every failed restoration represents a complete loss of materials and valuable technician time. The cost of a single remake often exceeds the cost of a professional calibration service.

Establishing a Robust Management Protocol

Effective furnace management relies on a structured and consistent approach that combines professional servicing with diligent in-house oversight.

Define a Formal Calibration Schedule

A furnace should be professionally calibrated according to a regular schedule, such as quarterly or semi-annually, depending on usage. This creates a reliable performance baseline.

Calibrate for Critical Cases

For highly complex or aesthetically demanding procedures, such as large-span bridges or anterior veneers, best practice dictates calibrating the furnace immediately before the sintering cycle. This eliminates temperature as a potential variable if a problem arises.

Integrate Routine Inspections

Calibration is part of a larger maintenance picture. Regularly inspect key components like electrical connections, ventilation systems, and heating elements for signs of wear or damage. This can catch problems before they cause a catastrophic failure.

Understanding the Trade-offs

Implementing a rigorous calibration protocol involves balancing cost, time, and risk.

The Cost of Professional Service

Using a manufacturer-certified technician for calibration involves both a service fee and equipment downtime. This direct cost can seem prohibitive.

The Hidden Cost of Inaction

However, the cost of professional service is minimal compared to the compounding costs of failed restorations, wasted materials, and reputational damage from inconsistent results. An uncalibrated furnace is a significant financial risk.

The Burden of Frequency

Calibrating before every use provides the highest level of assurance but may be impractical for a high-volume lab. The key is to assess the complexity of the work and adjust the frequency accordingly.

Making the Right Choice for Your Lab

Your calibration strategy should align directly with the primary goals and demands of your laboratory's workflow.

- If your primary focus is high-volume production of standard crowns: A strict quarterly or semi-annual professional calibration schedule provides a reliable and cost-effective baseline.

- If your primary focus is complex, high-aesthetic cases: Calibrate more frequently, ideally before each critical sintering cycle, to eliminate all temperature-related variables.

- If your primary focus is maximizing equipment lifespan and preventing failures: Integrate your professional calibration schedule with a weekly in-house checklist for inspecting heating elements and electrical systems.

A disciplined approach to calibration turns a complex piece of equipment into a consistently reliable tool for clinical and aesthetic excellence.

Summary Table:

| Aspect | Uncalibrated Furnace Risk | Calibrated Furnace Benefit |

|---|---|---|

| Material Integrity | Under/over-sintering, leading to weak or brittle restorations | Predictable strength and structural integrity for zirconia, lithium disilicate, etc. |

| Aesthetic Quality | Inconsistent shade, opacity, and discoloration | Reliable shade matching and translucency for superior aesthetics |

| Cost & Efficiency | Wasted materials and technician time on remakes | Maximized productivity and minimized waste |

| Process Reliability | Introduces an unacceptable variable into a precision workflow | Transforms the furnace into a predictable, reliable instrument |

Achieve Uncompromising Precision in Your Dental Lab

Don't let an uncalibrated furnace compromise your restorations. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, CVD systems, and other lab high-temp furnaces, all customizable for your unique dental lab needs. Our reliable equipment, combined with a disciplined calibration protocol, is the foundation for clinical and aesthetic excellence.

Contact our experts today to discuss how KINTEK furnaces can enhance the predictability and quality of your workflow.

Visual Guide

Related Products

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the step-by-step process for making porcelain dental restorations? Master Precision and Aesthetics

- What should routine inspections of dental furnaces include? Ensure Consistent, High-Quality Dental Restorations

- What are the risks of inadequate dental furnace ventilation? Protect Your Lab Quality & Team Safety

- How does a vacuum porcelain furnace ensure the bonding quality? Achieve Superior Metal-Ceramic Restorations

- What is the use of porcelain in dentistry? Achieve Lifelike, Durable Dental Restorations