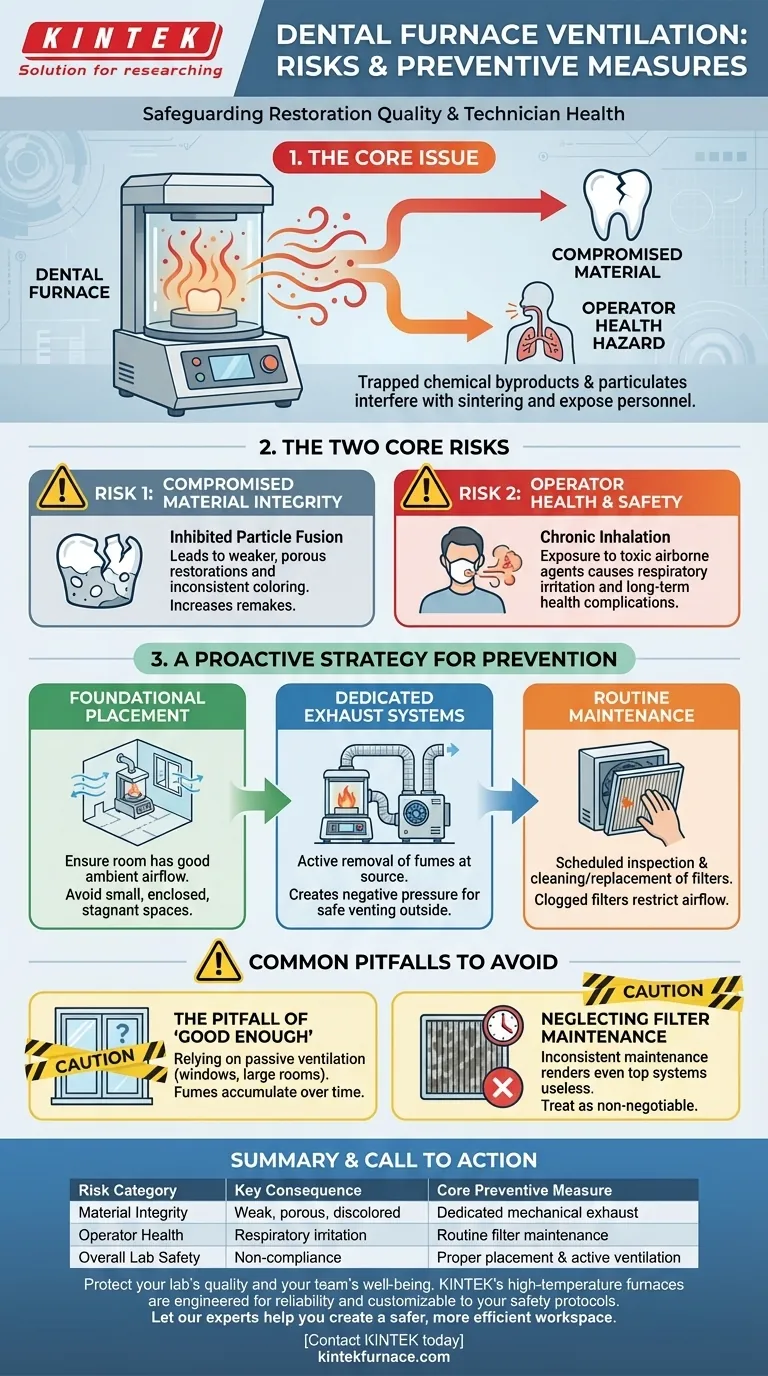

Inadequate ventilation for a dental furnace creates two primary risks: it compromises the quality and integrity of the sintered restorations, and it poses a significant health hazard to lab personnel from the buildup of harmful fumes. Preventive measures focus on ensuring consistent and effective airflow through proper furnace placement, dedicated exhaust systems, and routine maintenance.

The core issue is that the sintering process releases chemical byproducts and particulates. Without proper ventilation, these contaminants become trapped, directly interfering with the material's structural integrity and exposing operators to potentially toxic airborne agents.

The Two Core Risks of Poor Ventilation

Understanding the specific consequences of inadequate ventilation is the first step toward appreciating its importance. The risks are not theoretical; they have direct impacts on both your product quality and your team's well-being.

Risk 1: Compromised Material Integrity

The dental sintering process is a precise thermal treatment designed to create strong, dense, and aesthetically pleasing restorations.

Trapped fumes and gases in the furnace chamber can interfere with this delicate process. This contamination can inhibit the proper fusion of material particles, leading to restorations that are weaker, more porous, or have inconsistent coloring.

Ultimately, this results in poorly fitting crowns, bridges, or other prosthetics, increasing the rate of remakes and impacting the reputation of your lab.

Risk 2: Operator Health and Safety

The fumes released during the heating of zirconia, binding agents, and coloring liquids are not harmless water vapor.

These fumes can contain a mixture of airborne particulates and chemical vapors. Chronic inhalation in a poorly ventilated space can lead to respiratory irritation and other long-term health complications for your technicians.

This is not just a quality control issue; it is a fundamental matter of workplace safety and regulatory compliance.

A Proactive Strategy for Prevention

A multi-layered approach is the most effective way to mitigate the risks associated with dental furnace emissions. Relying on a single method is often insufficient.

Foundational Placement

The furnace must be installed in a room with good ambient airflow. Placing it in a small, enclosed, or stagnant space is the most common initial mistake.

This provides a baseline level of air exchange, but it should be considered the first step, not the complete solution.

Dedicated Exhaust Systems

For any professional or industrial setting, a passive, open window is not enough. A dedicated mechanical exhaust system is essential.

This system actively pulls fumes from the furnace area and vents them safely outside the building. It creates negative pressure that ensures contaminants are removed at the source before they can spread into the workspace.

Routine Maintenance and Inspection

An exhaust system is only effective if it is properly maintained. Ventilation filters will eventually become clogged with particulates.

Establish a regular schedule for inspecting and cleaning or replacing these filters. A clogged filter severely restricts airflow, rendering the entire ventilation system useless and recreating the hazardous conditions you sought to prevent.

Common Pitfalls to Avoid

Simply having a ventilation system in place doesn't guarantee safety or quality. Awareness of common failure points is critical for ensuring your preventive measures are truly effective.

The Pitfall of "Good Enough" Ventilation

Many labs assume that a large room or a nearby window constitutes adequate ventilation. This is a dangerous misconception.

Without an active exhaust system to capture and remove fumes at the source, these contaminants will inevitably accumulate in the room's atmosphere, affecting both materials and personnel over time.

Neglecting Filter Maintenance

The single most common point of failure in a ventilation plan is inconsistent maintenance. A top-of-the-line exhaust system with a completely clogged filter performs worse than no system at all.

Maintenance must be a scheduled, non-negotiable task, just like calibrating the furnace itself.

Making the Right Choice for Your Goal

Your approach to ventilation should be dictated by your commitment to professional standards for both quality and safety.

- If your primary focus is consistent product quality: A dedicated exhaust system is non-negotiable to prevent furnace atmosphere contamination and ensure predictable sintering outcomes.

- If your primary focus is team safety and compliance: Active ventilation and a strict filter maintenance schedule are fundamental requirements for creating a safe working environment and meeting health regulations.

Ultimately, robust ventilation is a cornerstone of any professional dental laboratory, safeguarding both your product and your people.

Summary Table:

| Risk Category | Key Consequence | Core Preventive Measure |

|---|---|---|

| Material Integrity | Weak, porous, or discolored restorations | Dedicated mechanical exhaust system |

| Operator Health | Respiratory irritation from toxic fumes | Routine filter maintenance & inspection |

| Overall Lab Safety | Non-compliance with health regulations | Proper furnace placement & active ventilation |

Protect your dental lab's quality and your team's well-being. Inadequate ventilation directly risks restoration failures and technician health. At KINTEK, we understand the precise demands of dental sintering. Our high-temperature furnaces are engineered for reliability and are fully customizable to integrate seamlessly with your lab's ventilation and safety protocols. Let our experts help you create a safer, more efficient workspace. Contact KINTEK today to discuss your specific furnace and ventilation needs.

Visual Guide

Related Products

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the step-by-step process for making porcelain dental restorations? Master Precision and Aesthetics

- How does a vacuum porcelain furnace ensure the bonding quality? Achieve Superior Metal-Ceramic Restorations

- What happens if the timing is incorrect during a dental furnace operation? Avoid Ruined Restorations

- What should routine inspections of dental furnaces include? Ensure Consistent, High-Quality Dental Restorations

- How does an efficient cooling system benefit dental furnace operations? Boost Productivity and Quality in Your Lab