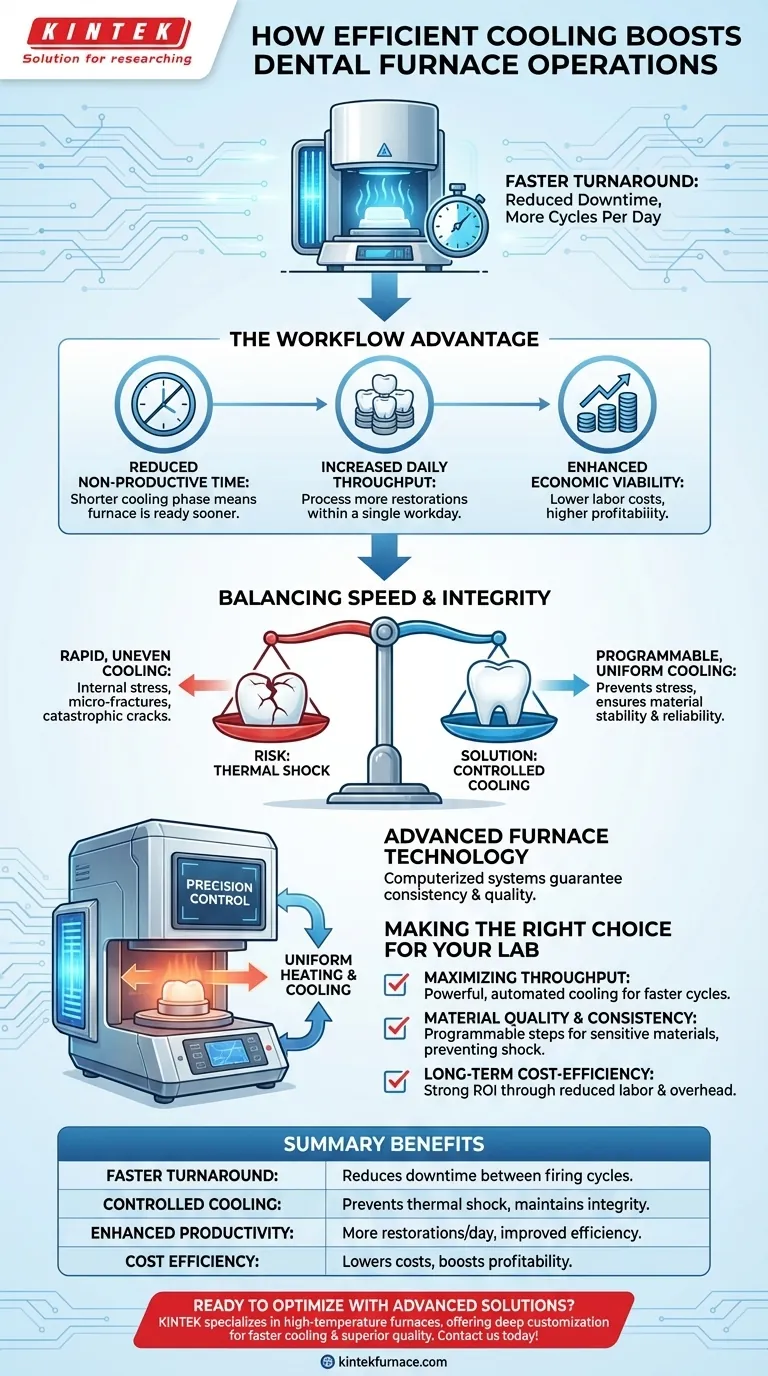

An efficient cooling system is a cornerstone of modern dental furnace operations, directly translating to faster turnaround times between firing cycles. This allows a dental lab to process more restorations in a single day, significantly boosting productivity and workflow efficiency without compromising the quality of the final product.

The primary benefit of an efficient cooling system is not just speed, but controlled speed. It accelerates the cooling phase without inducing thermal shock, ensuring that increased throughput does not come at the expense of material integrity and the structural quality of dental restorations.

The Link Between Cooling and Workflow Productivity

An efficient cooling system's main advantage is its impact on the furnace's total cycle time. By optimizing the final phase of the process, it creates cascading benefits throughout the entire dental lab workflow.

Reducing Non-Productive Time

A furnace can only begin a new cycle once it has cooled sufficiently from the previous one. An efficient system shortens this non-productive downtime, making the equipment available for the next job much sooner.

Increasing Daily Throughput

This reduction in downtime between cycles directly enables a lab to run more firing processes within a single workday. This capacity increase is crucial for labs looking to expand their output or handle urgent cases more effectively.

Enhancing Economic Viability

By shortening the production cycle for each restoration, an efficient furnace reduces the associated labor costs and overhead. This allows for greater profitability and a faster return on the equipment investment.

Understanding the Trade-offs: Speed vs. Structural Integrity

While speed is a major benefit, it cannot come at the cost of quality. The most critical function of an advanced cooling system is to manage the fine line between rapid cooling and material stability.

The Danger of Thermal Shock

Rushing the cooling phase without proper control can induce thermal shock. This rapid, uneven temperature change creates internal stresses within the ceramic material, leading to micro-fractures or catastrophic cracks in the final restoration.

How Efficient Cooling Mitigates Risk

A truly efficient cooling system is not merely a fan that blows air. It is a programmable, controlled process that lowers the temperature at an optimized rate. This ensures the entire restoration cools uniformly, preventing the stress that causes thermal shock.

Preserving Material Integrity

Proper cooling is a critical step for ensuring the sintered material achieves its intended structural properties, such as strength and durability. A controlled process ensures the final restoration is not just aesthetically pleasing but also clinically reliable.

The Role of Advanced Furnace Technology

Modern dental furnaces integrate cooling as part of a precise, computerized system designed for consistency and quality.

Precision and Computerized Control

Advanced furnaces use pre-programmed cycles that dictate exact heating and cooling rates. This removes guesswork and operator variability, guaranteeing that every restoration is processed under ideal conditions.

Uniform Heating and Cooling

The design of high-quality furnaces ensures that temperature—both hot and cold—is applied uniformly across the entire batch of materials. This consistency is key to producing high-quality dental products with reliable structural integrity.

Making the Right Choice for Your Lab

When evaluating a dental furnace, the cooling system should be a key consideration based on your specific operational goals.

- If your primary focus is maximizing throughput: Prioritize a furnace with a powerful, automated cooling system that significantly shortens downtime between cycles.

- If your primary focus is material quality and consistency: Look for a system with programmable cooling steps that give you precise control to prevent thermal shock, especially when working with sensitive materials.

- If your primary focus is long-term cost-efficiency: An efficient cooling system provides a strong return on investment by shortening production cycles and reducing the labor cost associated with each restoration.

Ultimately, investing in efficient cooling technology empowers your lab to achieve a critical balance between speed, quality, and profitability.

Summary Table:

| Benefit | Description |

|---|---|

| Faster Turnaround | Reduces downtime between firing cycles for increased throughput. |

| Controlled Cooling | Prevents thermal shock and maintains material integrity. |

| Enhanced Productivity | Allows more restorations per day, improving workflow efficiency. |

| Cost Efficiency | Lowers labor costs and overhead, boosting profitability. |

Ready to optimize your dental lab with advanced furnace solutions? KINTEK specializes in high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to precisely meet your unique needs—ensuring faster cooling, superior quality, and higher profitability. Contact us today to discuss how we can enhance your operations!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity