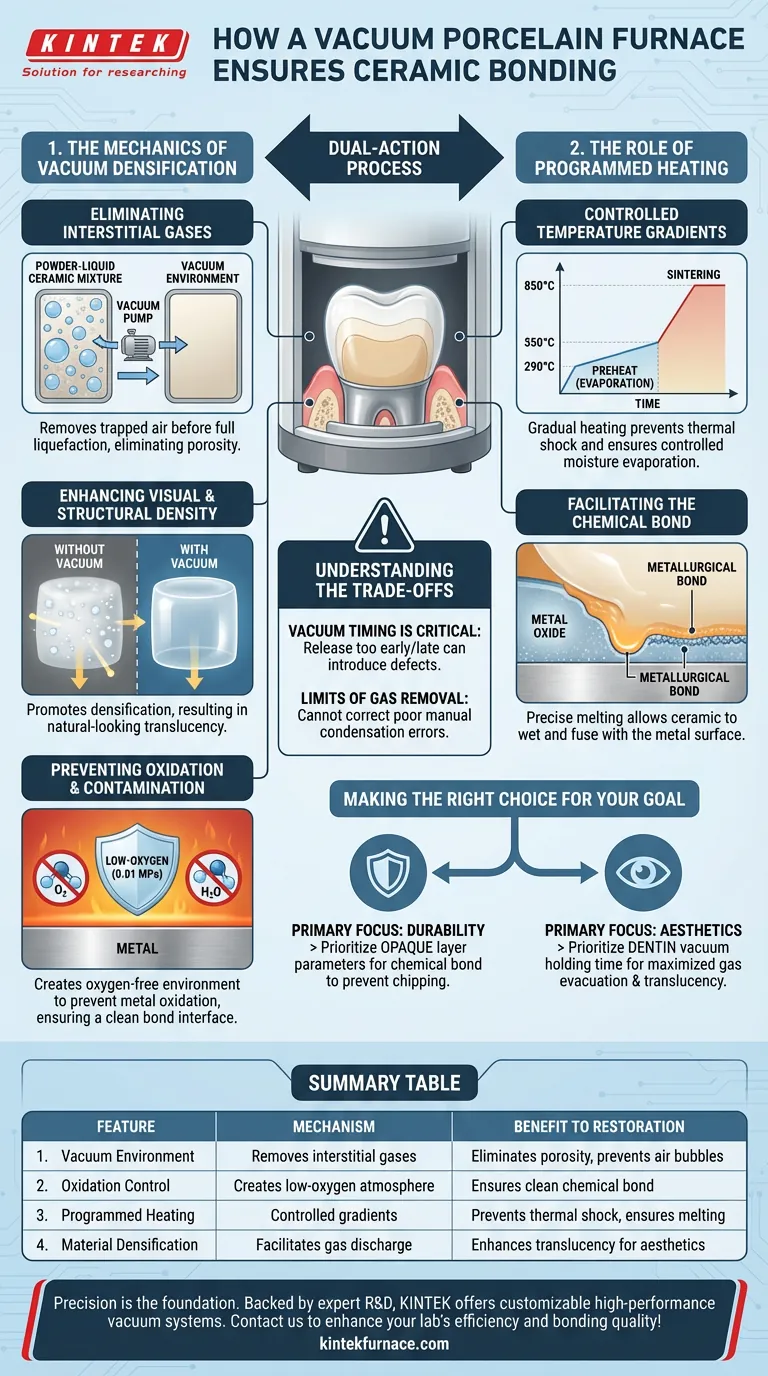

A vacuum porcelain furnace ensures bonding quality by synchronizing precise, programmed heating with a strictly controlled low-pressure environment. This dual-action process removes interstitial gases trapped between ceramic powder particles and prevents oxidation on the metal surface, creating the ideal conditions for a dense, durable chemical bond.

Core Takeaway By expelling residual gases and preventing oxidation, the vacuum environment allows ceramic particles to melt thoroughly into a solid mass. This creates a dense chemical bond at the metal-ceramic interface, which is critical for preventing chipping and ensuring the restoration can withstand clinical mechanical forces.

The Mechanics of Vacuum Densification

Eliminating Interstitial Gases

Ceramic layers are applied as a powder-liquid mixture. Interstitial spaces—tiny gaps filled with air—naturally exist between these powder particles.

Without a vacuum, these air pockets would become trapped during the melting phase, resulting in porosity. The vacuum environment actively draws these gases out before the ceramic fully liquefies, ensuring the final material is dense and void-free.

Enhancing Visual and Structural Density

The removal of air bubbles does more than just strengthen the material; it is essential for aesthetics.

Trapped gas bubbles scatter light, making the porcelain look opaque or milky. By facilitating the discharge of internal gases, the furnace promotes material densification, resulting in the translucency required to mimic natural tooth structure.

Preventing Oxidation and Contamination

High temperatures usually accelerate oxidation, which is detrimental to metal-ceramic bonding.

The vacuum creates an oxygen-free or low-oxygen environment (often reaching levels like 0.01 MPa). This prevents the metal matrix from oxidizing or reacting with harmful atmospheric components like water vapor and nitrogen, ensuring the interface remains chemically clean for bonding.

The Role of Programmed Heating

Controlled Temperature Gradients

Effective sintering is not just about getting hot; it is about how the heat is applied.

The furnace follows a specific schedule, such as preheating from 290°C to 850°C. This gradual increase prevents thermal shock and ensures that the moisture in the ceramic paste evaporates at a controlled rate before the vacuum seal is fully engaged.

Facilitating the Chemical Bond

The ultimate goal of the heating cycle is to form a chemical bond between the metal oxide layer and the opaque porcelain.

Precise temperature control allows the ceramic powder particles to melt thoroughly. This fluidity, combined with the clean vacuum environment, allows the ceramic to wet the metal surface completely, forming a continuous, strong metallurgical bond.

Understanding the Trade-offs

Vacuum Timing is Critical

The vacuum must be released at the exact right moment in the cooling cycle. If the vacuum is held too long or released too early, it can inadvertently introduce bubbles or cause surface defects in the porcelain.

The Limits of Gas Removal

While a vacuum is highly effective, it cannot correct errors in the manual application of the porcelain. If the ceramic is condensed poorly by the technician during the build-up phase, the furnace's vacuum system may not be able to remove all trapped air, leading to residual porosity despite the equipment's performance.

Making the Right Choice for Your Goal

To maximize the performance of your restorations, align your furnace settings with your specific clinical priorities:

- If your primary focus is Durability: Ensure your firing cycle prioritizes the "opaque" layer parameters, as this is where the chemical bond to the metal prevents chipping.

- If your primary focus is Aesthetics: Prioritize vacuum holding time during the "dentin" firing cycle to maximize gas evacuation and improve translucency.

Reliable clinical performance is the result of removing variables; the vacuum furnace achieves this by eliminating gas and oxidation to create a monolithic structure.

Summary Table:

| Feature | Mechanism | Benefit to Restoration |

|---|---|---|

| Vacuum Environment | Removes interstitial gases between particles | Eliminates porosity and prevents air bubbles |

| Oxidation Control | Creates low-oxygen atmosphere (0.01 MPa) | Ensures a clean chemical bond at the metal interface |

| Programmed Heating | Controlled gradients (e.g., 290°C to 850°C) | Prevents thermal shock and ensures complete melting |

| Material Densification | Facilitates discharge of internal gases | Enhances translucency for natural-looking aesthetics |

Precision is the foundation of durable dental restorations. Backed by expert R&D and manufacturing, KINTEK offers high-performance vacuum systems and lab high-temp furnaces tailored for dental and industrial excellence. Whether you need Muffle, Tube, Rotary, or CVD systems, our equipment is fully customizable to meet your unique sintering requirements. Contact us today to discover how KINTEK’s advanced heating solutions can enhance your laboratory's efficiency and bonding quality!

Visual Guide

References

- Haitham Elbishari, Nabeel H. M. Alsabeeha. The Impact of Recasting on the Bond Strength of Metal Ceramic Restorations. DOI: 10.2174/0118742106280608231227055226

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- How does a dental sintering furnace ensure precision and quality in dental restorations? Achieve Perfect Fits and Aesthetics

- What is a combination furnace in dental laboratories? Streamline Your Dental Lab Workflow with One Device

- What is the overall importance of a porcelain furnace machine in dentistry? Essential for Durable, Aesthetic Dental Restorations

- What are the main applications of a dental porcelain furnace? Precision Firing for Crowns, Veneers, and Bridges

- What are the two main types of porcelain furnaces? Choose the Right Furnace for Superior Dental Restorations

- What materials can be processed in a dental zirconia sintering furnace? Essential Guide for Dental Labs

- How do advanced cooling systems in sintering furnaces help? Achieve Crack-Free, High-Quality Dental Restorations

- What does the firing cycle in a dental ceramic furnace consist of? Master Precision for Perfect Restorations