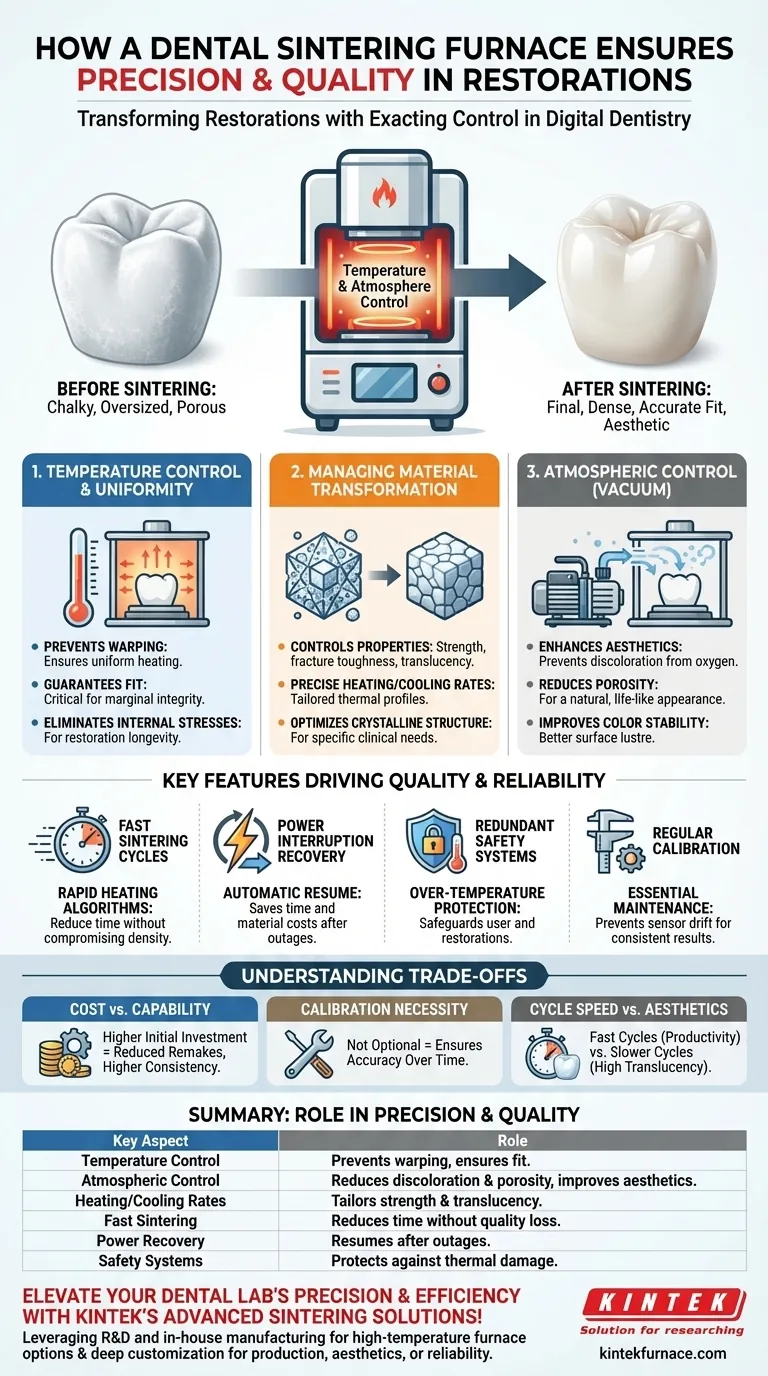

In digital dentistry, precision is the foundation of clinical success. A dental sintering furnace ensures this precision and quality by transforming a chalky, oversized dental restoration into its final, dense form through the exacting control of temperature and atmosphere. This process is what guarantees the strength, accuracy of fit, and aesthetic properties required for a successful clinical outcome.

The core function of a sintering furnace is not simply to heat a material, but to manage a complex material transformation with extreme accuracy. Its ability to execute pre-programmed heat cycles and control the firing environment dictates whether a restoration will fit perfectly or fail completely.

The Core Mechanisms of Sintering Precision

A modern dental furnace is a sophisticated instrument. Its value lies in its ability to precisely manage the physical and chemical changes that occur within materials like zirconia and ceramics at extreme temperatures.

The Critical Role of Temperature Control

Sintering involves heating a porous material to a temperature below its melting point, causing its particles to fuse together and densify. For this to happen correctly, uniform temperature throughout the furnace chamber is paramount.

Uneven heating causes different parts of the restoration to shrink at different rates, leading to warping and internal stresses. This directly compromises the marginal fit, which is critical for preventing secondary caries and ensuring longevity. Advanced heating elements and intelligent control systems work together to ensure temperature uniformity to within a few degrees.

Managing Material Transformation

The final properties of a restoration—its strength, fracture toughness, and translucency—are determined by its final crystalline structure. This structure is a direct result of the heating and cooling rates controlled by the furnace.

Slower or multi-stage cycles can be programmed to achieve higher translucency for aesthetic anterior crowns, while faster cycles might be prioritized for strength in posterior restorations. The furnace's ability to precisely execute these complex thermal profiles is what allows technicians to tailor the material properties to the specific clinical need.

The Importance of Atmospheric Control

The atmosphere inside the furnace during firing has a significant impact on aesthetics. For porcelain restorations, a vacuum is often created within the furnace.

Removing air prevents oxygen from reacting with the ceramic materials, which would otherwise cause discoloration and porosity. This vacuum environment leads to restorations with better color stability, reduced porosity, and enhanced surface lustre, creating a more natural and life-like appearance.

Key Features That Drive Quality and Reliability

Beyond core temperature and atmospheric management, several features enhance the precision and productivity of a dental lab.

Fast Sintering Cycles

Modern furnaces offer "fast sintering" cycles that can dramatically reduce processing time. This is achieved not by simply heating faster, but through advanced control algorithms that rapidly heat the material without introducing thermal shock or compromising its final density and strength.

Power Interruption Recovery

A power outage during a multi-hour sintering cycle can ruin an entire batch of restorations. Furnaces with power interruption recovery can automatically resume the cycle once power is restored, saving significant time and material cost while ensuring the process completes as intended.

Redundant Safety Systems

Features like over-temperature protection and automatic shut-off systems are critical. They not only protect the user and the equipment but also safeguard the dental restorations from a catastrophic thermal event that would render them unusable.

Understanding the Trade-offs

While advanced furnaces offer superior control, it's important to understand the associated considerations.

The Cost vs. Capability Equation

Furnaces with the most precise temperature controls, advanced atmospheric options, and productivity features carry a higher initial investment. The trade-off is between this upfront cost and the long-term benefit of reduced remakes, higher consistency, and greater material versatility.

The Necessity of Calibration

A furnace's precision is only as good as its last calibration. Temperature sensors can drift over time, leading to inaccurate firing and inconsistent results. Regular calibration is not an optional maintenance step; it is essential for ensuring the furnace continues to deliver high-quality, predictable outcomes.

Cycle Speed vs. Aesthetics

While fast sintering is a valuable feature for productivity, it can be a trade-off. For some advanced zirconia materials, a slower, longer firing cycle is necessary to achieve the highest levels of translucency. Labs must balance the need for speed with the aesthetic demands of a specific case.

Making the Right Choice for Your Goal

Selecting a furnace requires aligning its capabilities with the primary goals of your dental practice or lab.

- If your primary focus is high-volume production: Prioritize furnaces with validated fast sintering cycles and robust power-loss recovery features to maximize throughput without sacrificing consistency.

- If your primary focus is high-end aesthetic restorations: Look for furnaces with superior atmospheric control (like vacuum capabilities for porcelain) and highly programmable, multi-stage firing cycles.

- If your primary focus is long-term reliability: Emphasize furnaces with proven, high-quality heating elements and user-friendly calibration procedures to ensure predictable outcomes for years to come.

Ultimately, investing in a high-fidelity sintering furnace is an investment in predictable outcomes and the quality of your clinical work.

Summary Table:

| Key Aspect | Role in Precision & Quality |

|---|---|

| Temperature Control | Ensures uniform heating to prevent warping and ensure marginal fit |

| Atmospheric Control | Uses vacuum to reduce discoloration and porosity for better aesthetics |

| Heating/Cooling Rates | Tailors material properties like strength and translucency |

| Fast Sintering Cycles | Reduces processing time without compromising quality |

| Power Interruption Recovery | Automatically resumes cycles after outages to save time and materials |

| Safety Systems | Protects restorations and equipment from thermal damage |

Elevate your dental lab's precision and efficiency with KINTEK's advanced sintering solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs, whether for high-volume production, high-end aesthetics, or long-term reliability. Contact us today to discuss how our tailored solutions can enhance your dental restorations and drive success in your practice!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Spark Plasma Sintering SPS Furnace

People Also Ask

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab