A dental porcelain furnace is a cornerstone of the modern dental laboratory, used primarily for firing, sintering, pressing, and glazing various ceramic materials. These controlled heating processes are what transform shapeless powders or wax patterns into strong, durable, and aesthetically pleasing dental restorations like crowns, veneers, and bridges. Without this equipment, creating high-quality, life-like prosthetics would be impossible.

The true purpose of a dental porcelain furnace extends beyond simple heating. It is a precision instrument designed to manipulate the microstructure of dental ceramics, providing the exact atmospheric and thermal conditions required to achieve optimal strength, fit, and aesthetics in the final restoration.

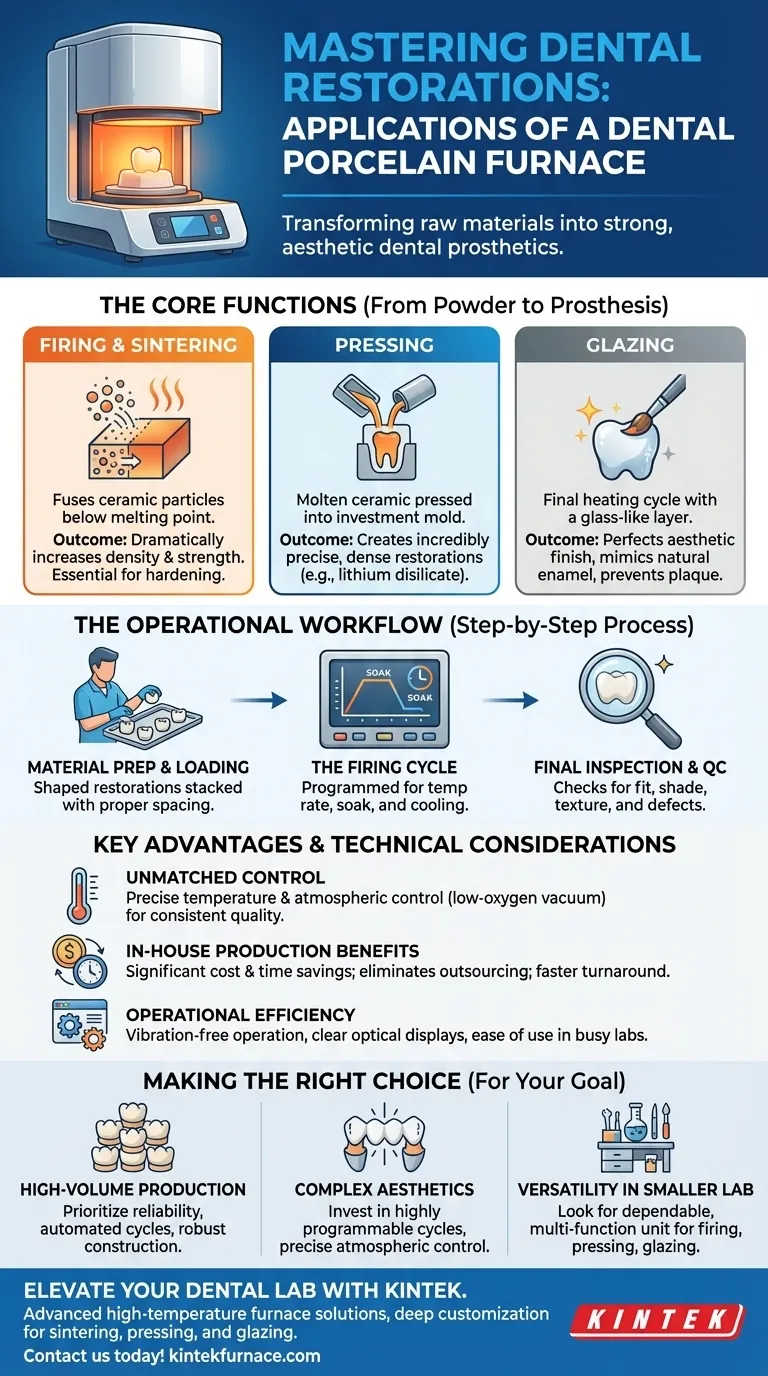

The Core Functions: From Powder to Prosthesis

A porcelain furnace executes several distinct thermal processes, each critical to a different stage of creating a dental restoration. Understanding these functions reveals how a lab technician guides a material from its raw state to a finished product.

Firing and Sintering: Building Strength

The most fundamental application is sintering, a process where heat is applied to ceramic particles just below their melting point.

This causes the particles to fuse, reducing porosity and dramatically increasing the material's density and strength. Firing is the general term for this heat treatment, which is essential for hardening and strengthening nearly all dental ceramics.

Pressing: Achieving Precision Form

For materials like lithium disilicate, the furnace is used for press-ceramic techniques.

A wax pattern of the final restoration is created and encased in an investment material. Inside the furnace, the wax is burned out, and a ceramic ingot is heated until molten and then "pressed" into the resulting mold, creating an incredibly precise and dense restoration.

Glazing: Perfecting the Aesthetic Finish

Glazing is the final heating cycle, applied after the restoration has been shaped and colored.

A thin layer of glass-like porcelain is applied and fired at a specific temperature. This creates a smooth, lustrous, and non-porous surface that mimics the appearance of natural tooth enamel while also preventing plaque accumulation.

The Operational Workflow in Practice

The furnace's applications are integrated into a precise, multi-step workflow that demands both technical skill and material science knowledge.

Material Preparation and Loading

Before any heating can begin, the restorations are carefully shaped, contoured, and stacked on firing trays. Technicians must ensure proper spacing between units to allow for uniform heat distribution, which is critical for preventing warping or stress fractures.

The Firing Cycle: A Programmed Transformation

This is the heart of the process. The technician selects a specific firing program based on the ceramic manufacturer's instructions. The program dictates the rate of temperature increase, the maximum temperature, the "soak" time at that temperature, and the cooling rate. Each variable is critical for achieving the desired material properties.

Final Inspection and Quality Control

After the firing cycle is complete and the restorations have cooled, they are meticulously inspected. The technician checks for proper fit, shade, surface texture, and any potential defects. This quality control step ensures the final product meets both functional and aesthetic clinical standards.

Key Advantages and Technical Considerations

Modern porcelain furnaces offer significant technical advantages that directly impact the quality and efficiency of a dental lab's output. These features are what elevate the furnace from a simple oven to a sophisticated production tool.

Unmatched Temperature and Atmospheric Control

The defining feature of a quality furnace is its ability to execute firing programs with extreme accuracy. Automatic temperature calibration ensures consistent results from one cycle to the next. Many advanced units also control the atmosphere, creating a low-oxygen vacuum to enhance material purity and prevent discoloration.

In-House Production Benefits

Owning a reliable furnace gives a dental lab complete control over its production. This leads to significant cost and time savings by eliminating the need for outsourcing. It also allows for superior customization and faster turnaround times for adjustments, enhancing the quality of service for clinicians and patients.

Operational Efficiency

Modern furnaces are designed for ease of use in a busy lab environment. Features like a precision stepper motor drive ensure quiet, vibration-free operation, which is crucial when lifting delicate restorations. Clear optical displays provide real-time feedback on the furnace's status, allowing technicians to monitor the process at a glance.

Making the Right Choice for Your Goal

Selecting a dental porcelain furnace depends entirely on the specific needs and priorities of your laboratory.

- If your primary focus is high-volume production: Prioritize furnaces known for their reliability, automated firing cycles, and robust construction to handle a demanding workload.

- If your primary focus is complex aesthetic restorations: Invest in a model with highly programmable cycles and precise atmospheric control to master advanced materials like zirconia and lithium disilicate.

- If your primary focus is versatility in a smaller lab: Look for a dependable, multi-function unit that can efficiently handle firing, pressing, and glazing for a wide range of common dental ceramics.

Ultimately, the right furnace empowers a dental laboratory to control the entire restoration process, ensuring every product meets the highest standards of function and beauty.

Summary Table:

| Application | Key Function | Outcome |

|---|---|---|

| Firing/Sintering | Fuses ceramic particles below melting point | Increases strength and density |

| Pressing | Melts and presses ceramic into molds | Creates precise, dense restorations |

| Glazing | Applies and fires a glass-like layer | Enhances aesthetics and prevents plaque |

Elevate your dental lab's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored for dental laboratories. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering superior performance for sintering, pressing, and glazing applications. Contact us today to discuss how we can enhance your production efficiency and restoration quality!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab