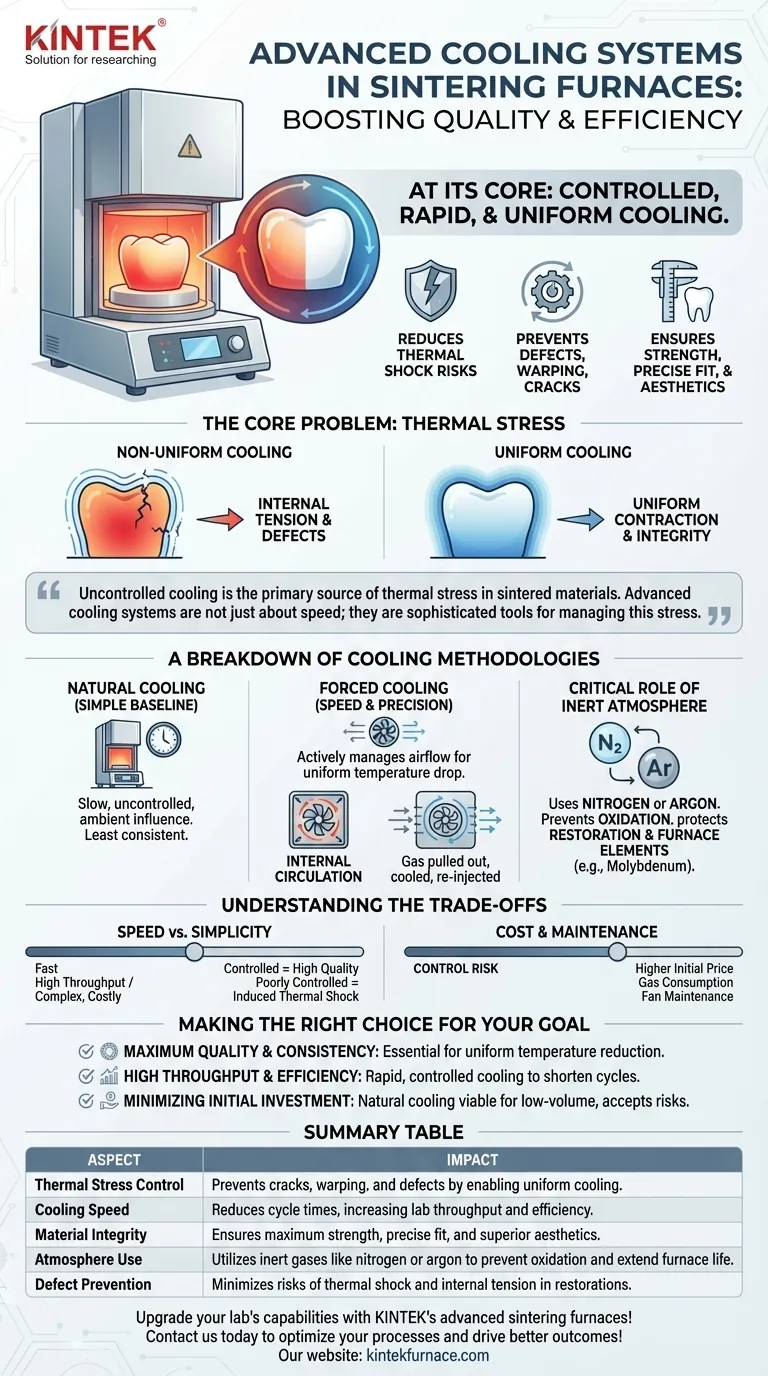

At its core, an advanced cooling system in a sintering furnace provides control over the most critical phase of creating a dental restoration. By enabling rapid yet uniform cooling, these systems dramatically reduce the risk of thermal shock, which prevents cracks, warping, and other defects. This ensures the final prosthetic has maximum strength, a precise fit, and superior aesthetic quality.

Uncontrolled cooling is the primary source of thermal stress in sintered materials. Advanced cooling systems are not just about speed; they are sophisticated tools for managing this stress, directly translating to higher quality, greater consistency, and improved lab efficiency.

The Core Problem: Thermal Stress During Cooling

To understand the value of advanced cooling, you must first understand the physics of what happens when a material like zirconia cools from its sintering temperature of over 1500°C.

How Non-Uniform Cooling Creates Defects

As a restoration cools, it contracts. If one part of the restoration cools faster than another—for instance, the thin outer edges cooling before the dense core—it creates immense internal tension.

This tension, known as thermal stress, is the root cause of most post-sintering failures. The material is literally being pulled apart from the inside.

The Impact on Dental Restorations

When thermal stress exceeds the material's structural integrity, defects appear. These can range from microscopic fissures that compromise long-term stability to full-blown fractures that render the restoration useless.

Even if the restoration doesn't crack, this stress can cause warping, leading to a poor marginal fit—a critical failure in dental prosthetics.

A Breakdown of Cooling Methodologies

Sintering furnaces employ several methods to manage this cooling process, ranging from simple to highly sophisticated.

Natural Cooling: The Simple Baseline

Natural cooling involves simply letting the furnace and its contents cool down on their own. This process is slow, often taking several hours.

While simple and requiring no extra machinery, it offers the least amount of control. The cooling rate is heavily influenced by ambient room temperature and air currents, leading to less consistent results.

Forced Cooling: Speed and Precision

Forced cooling actively accelerates the process using circulated air or inert gas. This is the foundation of all advanced cooling systems.

By actively managing airflow, the furnace can achieve a much faster and, more importantly, a more uniform temperature drop across the entire restoration.

Internal vs. External Circulation

Forced cooling is typically achieved in one of two ways. Internal circulation uses fans within the furnace chamber to move the heated atmosphere around, equalizing the temperature.

External circulation pulls the hot gas out of the chamber, runs it through a heat exchanger to cool it, and then injects the cooled gas back in. This provides an even greater degree of control and speed.

The Critical Role of an Inert Atmosphere

Advanced cooling systems don't just circulate air; they use specific gases to create a controlled, oxygen-free environment.

Why Nitrogen or Argon is Used

The medium used for forced cooling is typically a high-purity inert gas like nitrogen or argon.

At the extreme temperatures inside a furnace, oxygen can react with and degrade both the restoration and the furnace's heating elements (often made of molybdenum). An inert gas creates a protective, non-reactive atmosphere.

Protecting the Furnace and the Restoration

Using an inert atmosphere prevents oxidation, preserving the structural integrity and color stability of the zirconia restoration.

It also significantly extends the life of the furnace's expensive heating elements, reducing long-term maintenance costs and downtime.

Understanding the Trade-offs

While advanced cooling offers clear benefits, it's important to understand the associated considerations.

Speed vs. Simplicity

A furnace with advanced forced cooling will complete a cycle much faster than one relying on natural cooling, significantly increasing a lab's daily throughput. However, this comes at the cost of increased mechanical complexity.

The Risk of Poorly Controlled Cooling

Speed is only a benefit when it is controlled. A forced cooling system that is overly aggressive or creates a non-uniform draft can actually induce thermal shock and cause the very cracks it is meant to prevent.

Cost and Maintenance Considerations

Furnaces equipped with advanced cooling systems have a higher initial purchase price. They also introduce operational costs, such as the consumption of nitrogen or argon gas and maintenance for fans and circulation systems.

Making the Right Choice for Your Goal

The right cooling strategy depends entirely on your operational priorities and quality standards.

- If your primary focus is maximum quality and consistency: An advanced forced cooling system that ensures uniform temperature reduction is essential.

- If your primary focus is high throughput and efficiency: A system with rapid, controlled forced cooling is necessary to shorten cycle times and increase output.

- If your primary focus is minimizing initial investment: Natural cooling can be a viable option for low-volume labs, but you must accept slower turnaround times and a higher risk of inconsistent results.

Ultimately, mastering the cooling process is fundamental to mastering the quality and strength of your final restorations.

Summary Table:

| Aspect | Impact |

|---|---|

| Thermal Stress Control | Prevents cracks, warping, and defects by enabling uniform cooling |

| Cooling Speed | Reduces cycle times, increasing lab throughput and efficiency |

| Material Integrity | Ensures maximum strength, precise fit, and superior aesthetics |

| Atmosphere Use | Utilizes inert gases like nitrogen or argon to prevent oxidation and extend furnace life |

| Defect Prevention | Minimizes risks of thermal shock and internal tension in restorations |

Upgrade your lab's capabilities with KINTEK's advanced sintering furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering enhanced efficiency, consistency, and quality for dental restorations. Contact us today to discuss how our furnaces can optimize your sintering processes and drive better outcomes!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations